Functional starch and preparation method and application thereof

A functional, starch technology, applied in the application, function of food ingredients, food ingredients as antioxidants, etc., can solve the problem that phenols are difficult to maintain activity for a long time, light, heat, oxygen is unstable, and polyphenols are not stable. Material protection and other issues, to achieve the effect of strong practical performance, guarantee stability and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 10g (dry weight) of ordinary cornstarch, add 100mL of phosphate buffer solution with pH 4.0 and 0.1g of α-amylase to hydrolyze at 30°C for 3min, add 50mL of 70% ethanol solution to inactivate the enzyme treatment; then at room temperature, add Gallic acid with 35% dry weight of starch, mixed at 3000rpm for 20min; washed with 200mL distilled water three times. After centrifugation, the material is dried at 35°C, crushed, and sieved to obtain a relatively high content of slow-digesting and resistant-digestible starch products.

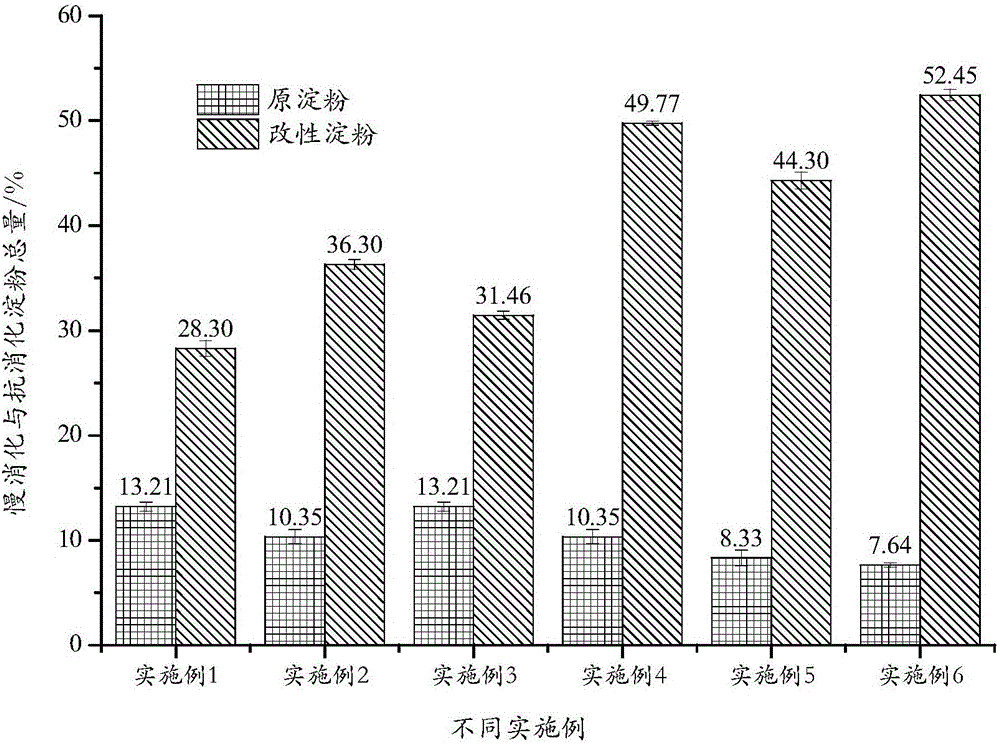

[0027] Using the Englyst method to measure the digestibility of the sample, the sum of the slowly digestible and resistant starch content is 28.30 ± 0.75%; while the sum of the slowly digestible and resistant starch content in the untreated control sample is 13.21 ± 0.43%, indicating that the processing method can Significantly increase the content of slowly digestible and resistant starch, suitable for processing and manufacturing functiona...

Embodiment 2

[0029] Weigh 15g (dry weight) of waxy cornstarch, add 100mL of phosphate buffer solution with pH 4.0 and 1.5g of α-amylase for enzymolysis at 37°C for 6min, add 50mL of 70% ethanol solution to inactivate the enzyme treatment; then at room temperature, Add green tea extract (the main component is catechin) with 50% starch dry basis, mix at 4000rpm for 30min; wash with 200mL distilled water three times. After centrifugation, the material is dried at 40°C, crushed, and sieved to obtain a relatively high content of slow-digesting and resistant-digestible starch products.

[0030] The digestibility of the sample was measured by the Englyst method, and the sum of the slowly digestible and resistant starch content was 36.30 ± 0.46%; while the sum of the slow digestible and resistant starch content in the untreated control sample was 10.35 ± 0.67%, indicating that the processing method can Significantly increase the content of slowly digestible and resistant starch, suitable for proce...

Embodiment 3

[0032] Weigh 10g (dry weight) of ordinary cornstarch, add 80mL of phosphate buffer solution with pH 4.0 and 0.8g of α-amylase for enzymolysis at 30°C for 5min, add 45mL of 70% ethanol solution to inactivate the enzyme treatment; then at room temperature, add Chlorogenic acid with 40% dry weight of starch, mixed at 4000rpm for 20min; washed with 200mL distilled water three times. After centrifugation, the material is dried at 35°C, crushed, and sieved to obtain a relatively high content of slow-digesting and resistant-digestible starch products.

[0033] The digestibility of the sample was measured by the Englyst method, and the sum of the slowly digestible and resistant starch content was 31.46 ± 0.39%; while the sum of the slowly digestible and resistant starch content in the untreated control sample was 13.21 ± 0.43%, indicating that the processing method can Significantly increase the content of slowly digestible and resistant starch, suitable for processing and manufacturi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com