Preparation method of MCM-41 mesoporous molecular sieve with mixed doping of Bi-La-Mo-Sr

A technology of mesoporous molecular sieve and MCM-41 is applied in the field of preparation of Bi-La-Mo-Sr mixed-doped MCM-41 mesoporous molecular sieve, which can solve the problems of poor crystallinity and poor stability, and achieves low cost and simple production. , the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

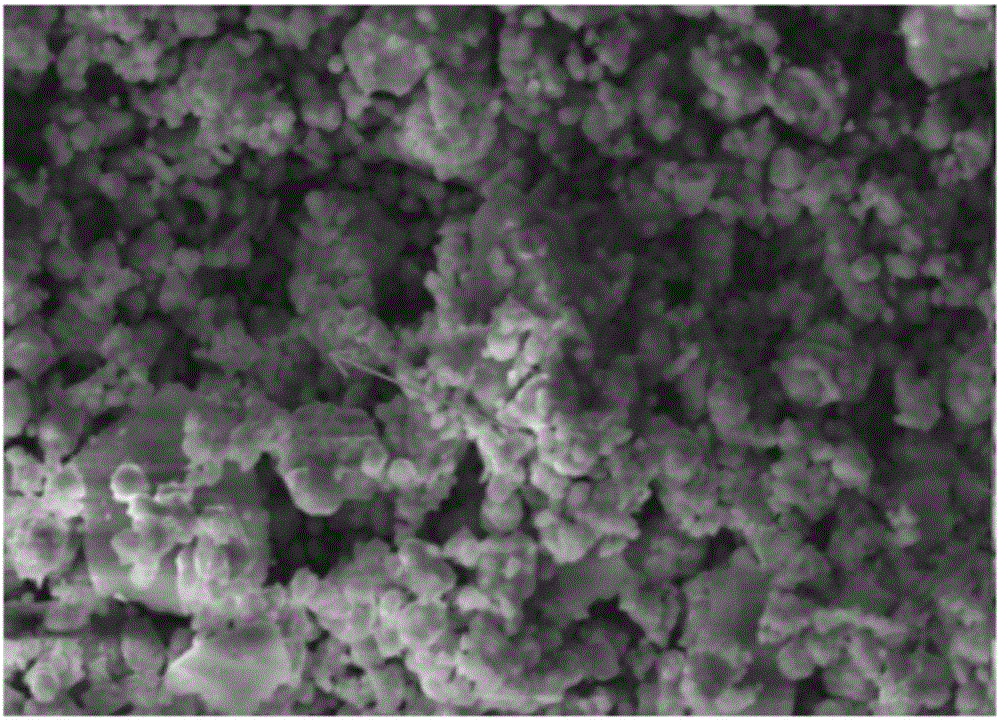

[0039] 1. Preparation of MCM-41 mesoporous molecular sieve:

[0040] ①. Use CTAB as a single template to prepare a homogeneous solution of cationic template

[0041] Weigh 2.2g of CTAB with an electronic balance, add it to the beaker A containing 43ml of distilled water measured in advance, and stir it evenly with a magnetic stirrer;

[0042] ②, adjust the pH of the cationic template solution

[0043] Take 13.0ml of ammonia water and 67.0ml of 95% ethanol in beaker B and stir evenly, pour the liquid in beaker B into beaker A, and adjust the pH to 7-8;

[0044] ③. Add inorganic silicon source to make it polycondensate with organic template

[0045] Slowly add 4.4ml of ethyl silicate (TEOS) dropwise to the pH-adjusted solution, and stir at room temperature for 2 hours to make the final mixed solution in a colloidal state. This process has been kept in a stirring state, so that the templating agent and silicon The source reacts completely;

[0046] ④. Transfer and crystallize...

Embodiment 2

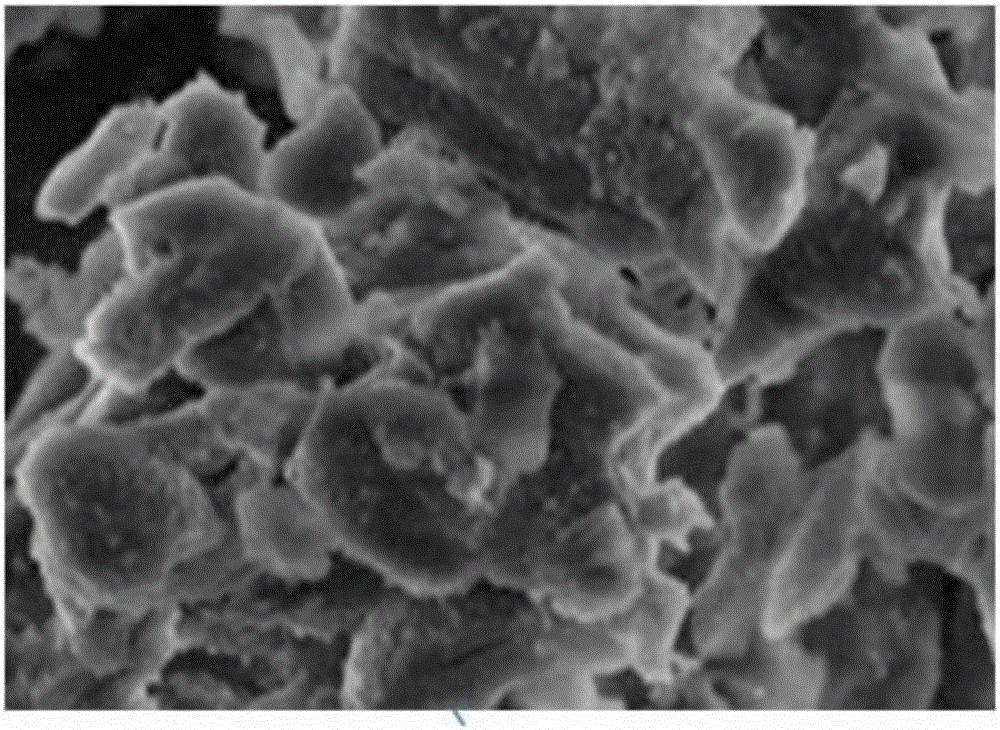

[0053] Preparation of Bi-doped MCM-41 mesoporous molecular sieve:

[0054] Weigh 0.4g of MCM-41 mesoporous molecular sieve and disperse it in a beaker filled with 35mL of 95% ethanol to form solution A, stir for 30min until the solution is completely mixed; then weigh 7.6g of bismuth chloride and disperse it in 15mL of 95% ethanol % ethanol, stirred evenly and slowly added dropwise to solution A, so that the two solutions were mixed, and continued to stir for 1h. During this process, heteroatoms were adsorbed on the surface of molecular sieves; then 5mL of 0.5M dilute hydrochloric acid was added dropwise Mix C solution with 10mL of distilled water, stir for 2h, then add 10mL of distilled water dropwise, continue stirring for 2h to ensure complete hydrolysis, centrifuge, wash with deionized water, dry at 50°C, calcined at 800°C for 4h, cool naturally, and grind Finally, Bi-doped MCM-41 mesoporous molecular sieves were obtained.

Embodiment 3

[0056] Preparation of La doped MCM-41 mesoporous molecular sieves:

[0057] Weigh 0.4g of MCM-41 mesoporous molecular sieve and disperse it in a beaker filled with 35mL of 95% ethanol to form solution A, stir for 30min until the solution is completely mixed; then weigh 5.2g of lanthanum chloride and disperse it in 15mL of 95% ethanol % ethanol, stirred evenly and slowly added dropwise to solution A, so that the two solutions were mixed, and continued to stir for 1h. During this process, heteroatoms were adsorbed on the surface of molecular sieves; then 5mL of 0.5M dilute hydrochloric acid was added dropwise Mix C solution with 10mL of distilled water, stir for 2h, then add 10mL of distilled water dropwise, continue stirring for 2h to ensure complete hydrolysis, centrifuge, wash with deionized water, dry at 50°C, calcined at 800°C for 4h, cool naturally, and grind Finally, La doped MCM-41 mesoporous molecular sieves were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com