Ultrasonic assisted nanometer aluminum oxide modified polyvinyl alcohol-sodium alginate embedding material, preparation method and applications thereof

A nano-alumina, polyvinyl alcohol technology, applied in chemical instruments and methods, aerobic and anaerobic process treatment, water/sludge/sewage treatment, etc., can solve the problem of high operating energy consumption, complex technical management, and infrastructure investment It can improve the pore structure, strengthen the effect, and improve the mass transfer performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: An ultrasonic-assisted nano-alumina modified polyvinyl alcohol-sodium alginate embedding material. The main components and contents are as follows (per 100mL of aqueous solution):

[0040] 10g of polyvinyl alcohol, 0.8g of sodium alginate, 0.5g of nano-alumina, and 10g of activated sludge.

[0041] Prepare as follows:

[0042] ① Preparation of polyvinyl alcohol-sodium alginate gel solution

[0043] Dissolve polyvinyl alcohol in a water bath at 90°C, then add sodium alginate to the polyvinyl alcohol solution, mix well, and cool to room temperature to obtain a polyvinyl alcohol-sodium alginate gel solution;

[0044] ②Add nano-alumina

[0045] Add nano-alumina to the polyvinyl alcohol-sodium alginate gel solution and mix well;

[0046] ③ Ultrasonic treatment

[0047] Put the mixed gel solution into the ultrasonic device, set the frequency to 40kHz, after ultrasonic treatment for 30min, let it stand until completely cooled;

[0048] ④Treatment of activated slu...

Embodiment 2

[0056] Example 2: An ultrasonic-assisted nano-alumina modified polyvinyl alcohol-sodium alginate embedding material. The main components and contents are as follows (per 100mL of aqueous solution):

[0057] 10g of polyvinyl alcohol, 0.1g of sodium alginate, 0.3g of nano-alumina, and 15g of activated sludge.

[0058] The preparation method is the same as in Example 1.

Embodiment 3

[0059] Example 3: An ultrasonic-assisted nano-alumina modified polyvinyl alcohol-sodium alginate embedding material. The main components and contents are as follows (per 100mL of aqueous solution):

[0060] 15g of polyvinyl alcohol, 1.0g of sodium alginate, 0.7g of nano-alumina, and 20g of activated sludge.

[0061] The preparation method is the same as in Example 1.

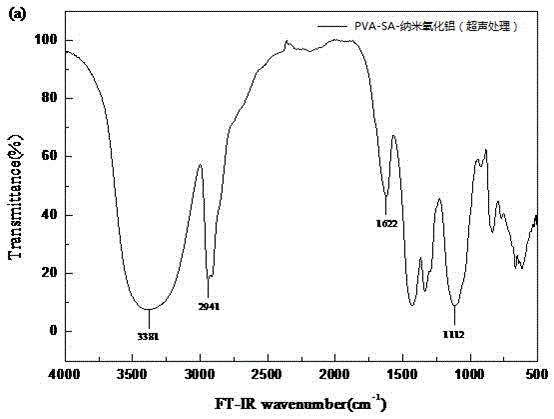

[0062] see figure 1 , at 3381cm -1 There is a strong transmission peak at , corresponding to the stretching vibration of the hydroxyl group (-OH), which is mainly due to the high hydrophilicity of polyvinyl alcohol leading to stretching vibrations of intermolecular and intramolecular hydrogen bonds. The characteristic peak is at 2941 cm -1 ,1622 cm -1 and 1112 cm -1 corresponding to the stretching vibrations of C-H, -COO and C-O respectively.

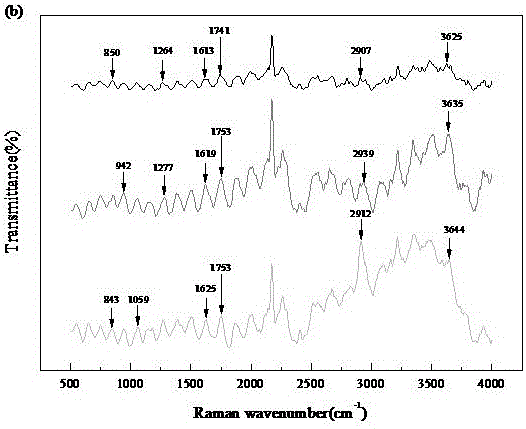

[0063] see figure 2 , which are the Raman spectra before and after material modification, from bottom to top are polyvinyl alcohol-sodium alginate, polyvinyl alco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com