A rare earth polishing solution and a preparing method thereof

A rare earth polishing and powder technology, applied in the field of polishing liquid, can solve problems such as slow speed, and achieve the effects of less human injury, excellent performance and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

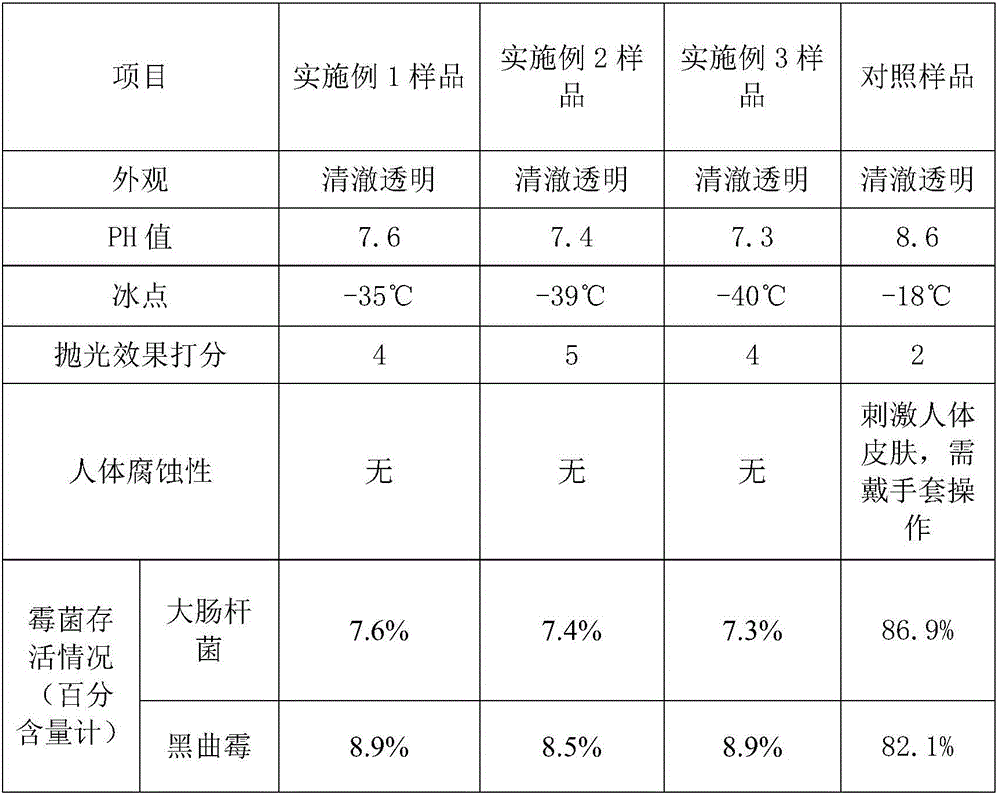

Embodiment 1

[0016] The rare earth polishing solution in this embodiment is composed of the following components in parts by mass: 18 parts of cerium oxide powder, 20 parts of magnesium sulfate, 16 parts of sandalwood oil, 14 parts of palygorskite powder, 20 parts of silicon oxide powder, chromium oxide 16 parts of powder, 14 parts of aminotrimethylene phosphonic acid, 20 parts of sodium tetraborate decahydrate, 16 parts of maleic anhydride, 14 parts of sodium benzoate, 20 parts of phthalate, 16 parts of hydroxyethylidene diphosphonic acid , 16 parts of p-nitrobenzoic acid, 14 parts of polyethylene glycol siloxane, 20 parts of trimethylolpropane, 16 parts of sodium hexametaphosphate, 14 parts of carbendazim, 20 parts of benzyltriphenylphosphine bromide , 16 parts of malic acid, 14 parts of octylphenol polyoxyethylene ether, 20 parts of potassium sorbate, 16 parts of amyl acetate, 14 parts of sodium gluconate, 20 parts of alcohol ether sulfosuccinic acid monoester disodium salt, diacylglycer...

Embodiment 2

[0022] The rare earth polishing solution in this embodiment is composed of the following components in parts by mass: 20 parts of cerium oxide powder, 22 parts of magnesium sulfate, 18 parts of sandalwood oil, 16 parts of palygorskite powder, 22 parts of silicon oxide powder, chromium oxide 18 parts of powder, 16 parts of aminotrimethylene phosphonic acid, 22 parts of sodium tetraborate decahydrate, 18 parts of maleic anhydride, 16 parts of sodium benzoate, 22 parts of phthalate, 18 parts of hydroxyethylidene diphosphonic acid , 18 parts of p-nitrobenzoic acid, 16 parts of polyethylene glycol siloxane, 22 parts of trimethylolpropane, 18 parts of sodium hexametaphosphate, 16 parts of carbendazim, 22 parts of benzyltriphenylphosphine bromide , 18 parts of malic acid, 16 parts of octylphenol polyoxyethylene ether, 22 parts of potassium sorbate, 18 parts of amyl acetate, 16 parts of sodium gluconate, 22 parts of alcohol ether sulfosuccinic acid monoester disodium salt, 22 parts of ...

Embodiment 3

[0028]The rare earth polishing solution in this embodiment is composed of the following components in parts by mass: 22 parts of cerium oxide powder, 24 parts of magnesium sulfate, 20 parts of sandalwood oil, 18 parts of palygorskite powder, 24 parts of silicon oxide powder, chromium oxide 20 parts of powder, 18 parts of amino trimethylene phosphonic acid, 24 parts of sodium tetraborate decahydrate, 20 parts of maleic anhydride, 18 parts of sodium benzoate, 24 parts of phthalate, 20 parts of hydroxyethylidene diphosphonic acid , 20 parts of p-nitrobenzoic acid, 18 parts of polyethylene glycol siloxane, 24 parts of trimethylolpropane, 20 parts of sodium hexametaphosphate, 18 parts of carbendazim, and 24 parts of benzyltriphenylphosphine bromide , 20 parts of malic acid, 18 parts of octylphenol polyoxyethylene ether, 24 parts of potassium sorbate, 20 parts of amyl acetate, 18 parts of sodium gluconate, 24 parts of alcohol ether sulfosuccinic acid monoester disodium salt, 24 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com