A kind of method for producing propionic acid by fermentation with mixed bacteria system

A system, propionic acid technology, applied in the field of microorganisms, can solve the problems of high input-output ratio, can not meet the needs of industrialization, limited strain sources, etc., and achieve the effect of low input and output, which is conducive to the implementation of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

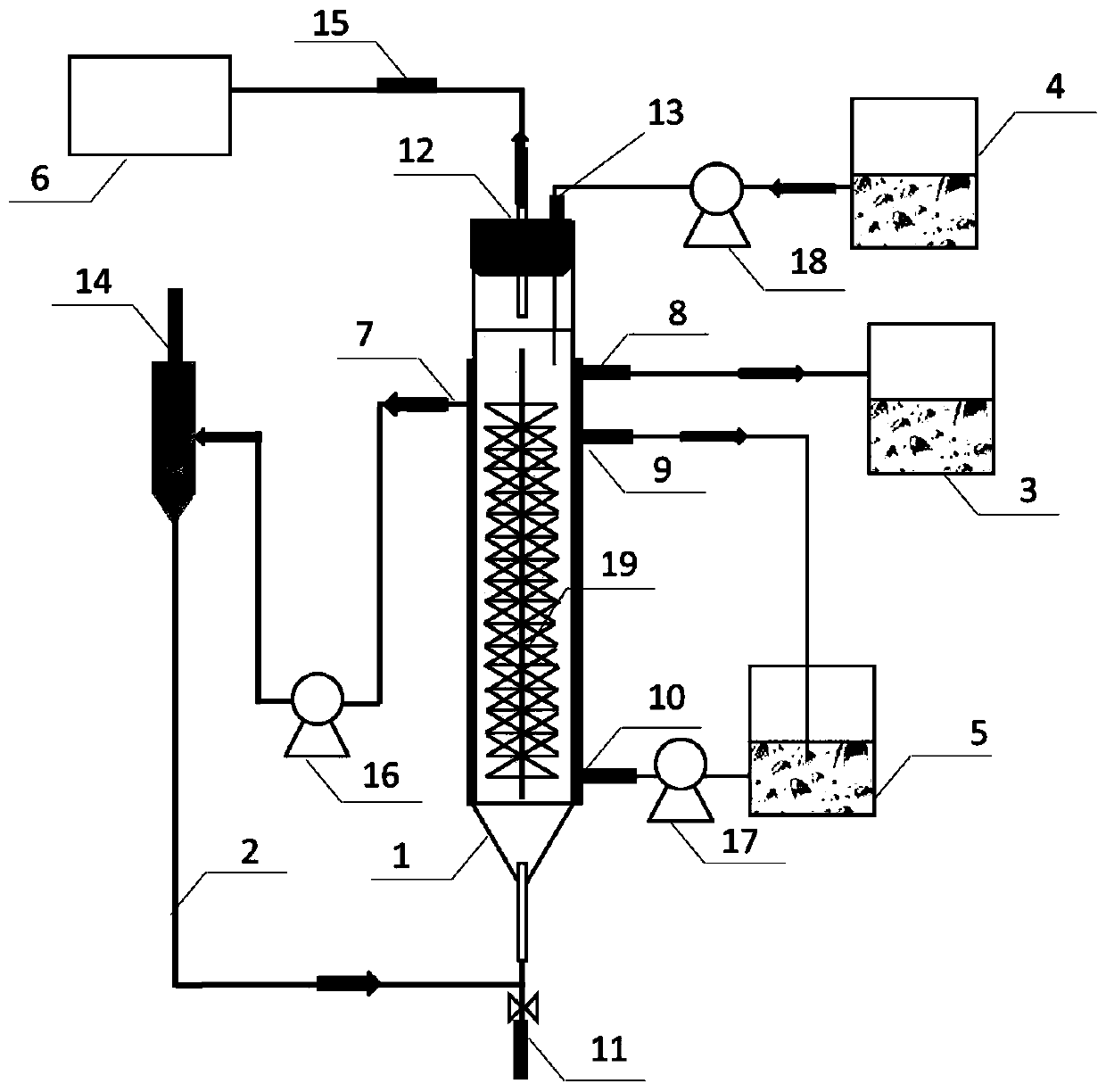

Image

Examples

Embodiment 1

[0042] Embodiment 1: fermentation method of the present invention (first round of fermentation)

[0043] The medium composition that this embodiment adopts is:

[0044] NH 4 Cl, 530mg / L; KH 2 PO 4 2H 2 O, 200mg / L; Na 2 SO 4 , 40mg / L; KCl, 50mg / L; CaCl 2 , 10mg / L; MgCl 2 ·6H 2 O, 70 mg / L; MnCl 2 4H 2 O, 0.8mg / L; CoCl 2 2H 2 O, 1.2mg / L; FeSO 4 ·7H 2 O, 3.2mg / L; AlCl 3 , 0.5mg / L; NaMO 4 2H 2 O, 1 mg / L; H 3 BO 3 , 0.2mg / L; NiCl 2 ·6H 2 O, 0.5mg / L; CuCl 2 2H 2 O, 1.1mg / L; ZnSO 4 2H 2 O, 3.2mg / L; EDTA (Na + type), 3.0mg / L.

[0045] The present embodiment anaerobic sludge flora composition:

[0046] Methanosaeta 8%, Methanobacterium 0.4%, Dethiosulfovibrionaceae 9.1%, Anaerolinaceae 7.1%, Streptococcaceae 6.9%, Syntrophobacteraceae 4.2%, Cloacamonaceae 3.7%, Syntrophorhabdaceae 3.5%, SB-1 3.4%, Geobacteraceae 3.1%, Clostridiaceae 2.5%, Porphyromonadaceae 1.9%, Pseudomonadaceae 1.7%, Syntrophomonadaceae 1.6%, [Tissierell...

Embodiment 2

[0056] Embodiment 2: fermentation method (second round of fermentation) of the present invention

[0057] The solid matter containing the flora of Example 1 and the anaerobic fermentation medium (same as Example 1) are used to form a fermentation system, the pH of the fermentation system is adjusted to 7.0-7.3, the temperature is 35-37°C, and the fermentation system is fed every day Add 5 g of glycerol to the fermentation system to make the concentration of organic matter between 0.1-5 g / L, and gradually increase the concentration of ammonium ions in the fermentation system at a rate of 0.3 g / (L·d) until the concentration of ammonium ions in the fermentation system is 1g / L, the process time is generally 7-20 days.

[0058] After the ammonium ion concentration in the fermentation system is stabilized at 1g / L, keep the ion concentration constant, and continue to add organic glycerol to the reaction system in the sequential batch mode to maintain the organic concentration between...

Embodiment 3

[0062] Embodiment 3: fermentation method of the present invention (first round+second round of fermentation)

[0063] According to the method of embodiment 1 and embodiment 2, with being different from the anaerobic sludge in the anaerobic fermentation tank of another sewage treatment plant of embodiment 1 as starting material, flora composition is as follows:

[0064] Methanosaeta 10%, Methanobacterium 2.5%, Anaerolinaceae 15.5%, Streptococcaceae 12.8%, Cloacamonaceae 6.5%, Thermotogaceae 6.2%, Dethiosulfovibrionaceae 4.2%, Ruminococcaceae 3.6%, Enterobacteriaceae 2.7%, Clostridiaceae 2.5%, Peptococcaceae 2.3%, Syntrophomonadaceae 1.9%, Porphyromonadaceae 1.7%, Geobacteraceae 1.7%, Gracilibacteraceae 1.6%, Synergistaceae 0.9%, Pseudomonadaceae 0.6%, Sphaerochaetaceae 0.5%, other 22.3% (content less than 0.5% and unclassified flora not listed).

[0065] After the first round of fermentation, it was tested that the purity of prop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com