A kind of preparation method of leaf-shaped nanometer gamma-alumina

An alumina and blade-like technology, which is applied in the field of synthesis of nanometer γ-alumina carriers with high specific surface area, can solve the problem of high equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

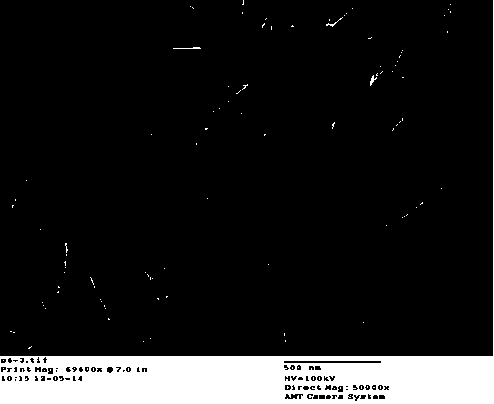

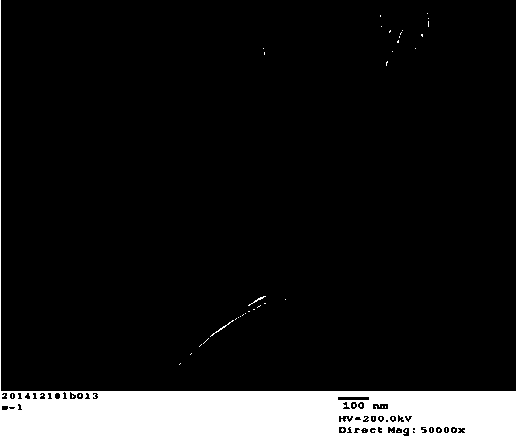

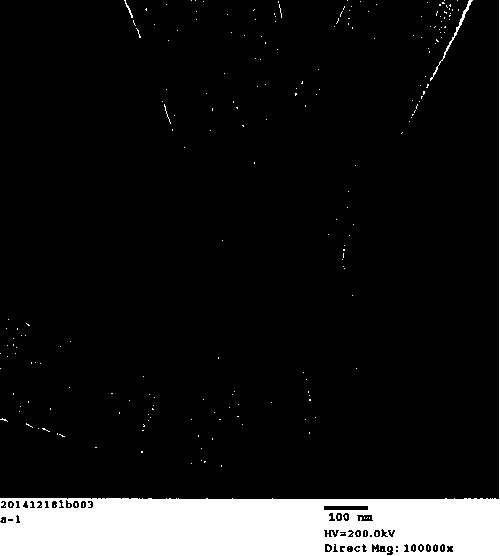

Image

Examples

Embodiment 1

[0025] Add 7.5g of aluminum nitrate and 6g of urea into 70mL of deionized water, and stir magnetically for 20 minutes to obtain a colorless and transparent solution. Then the solution was transferred to the autoclave, and hydrogen gas was introduced to discharge the air in the autoclave, and then the hydrogen pressure in the autoclave was set to 0.5 MPa, and the autoclave was sealed. The temperature of the reaction kettle was raised to 120° C., and the reaction was carried out for 24 hours. After the reaction, the reaction kettle was naturally cooled to room temperature, the gas in the reaction kettle was discharged, the reaction kettle was opened, and the reaction slurry was collected. The reaction slurry was suction-filtered, and the filtrate was washed repeatedly with deionized water for 3 times, and then transferred to an oven at 80° C. for drying for 8 hours to obtain boehmite, a precursor of γ-alumina. Finally, put the boehmite into a muffle furnace for roasting, raise ...

Embodiment 2

[0027] Add 6.6g of aluminum sulfate and 6g of urea into 70mL of deionized water, and stir magnetically for 20 minutes to obtain a colorless and transparent solution. Then the solution was transferred to the autoclave, and hydrogen gas was introduced to discharge the air in the autoclave, and then the hydrogen pressure in the autoclave was set to 0.5 MPa, and the autoclave was sealed. The temperature of the reaction kettle was raised to 120° C., and the reaction was carried out for 24 hours. After the reaction, the reaction kettle was naturally cooled to room temperature, the gas in the reaction kettle was discharged, the reaction kettle was opened, and the reaction slurry was collected. The reaction slurry was suction-filtered, and the filtrate was washed repeatedly with deionized water for 3 times, and then transferred to an oven at 80° C. for drying for 8 hours to obtain boehmite, a precursor of γ-alumina. Finally, put the boehmite into a muffle furnace for roasting, raise ...

Embodiment 3

[0029] Add 7.5g of aluminum nitrate and 6g of urea into 70mL of deionized water, and stir magnetically for 20 minutes to obtain a colorless and transparent solution. Then the solution was transferred to an autoclave, and hydrogen gas was introduced to discharge the air in the autoclave, and then the hydrogen pressure in the autoclave was set to 0.4 MPa, and the autoclave was sealed. The temperature of the reaction kettle was raised to 140° C., and the reaction was carried out for 12 hours. After the reaction, the reaction kettle was naturally cooled to room temperature, the gas in the reaction kettle was discharged, the reaction kettle was opened, and the reaction slurry was collected. The reaction slurry was suction-filtered, and the filtrate was washed repeatedly with deionized water for 3 times, and then transferred to an oven at 80° C. for drying for 8 hours to obtain boehmite, a precursor of γ-alumina. Finally, put the boehmite into a muffle furnace for roasting, raise t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com