Special organic fertilizer for kidney beans, and application method and preparation method thereof

A technology of organic fertilizer and kidney bean, applied in the application, fertilization device, fertilizer mixture and other directions, can solve the problems of low relative content, unreasonable ratio, fertilizer waste, etc., to achieve strong adsorption capacity, improve quality, and reduce the effect of fertilization cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

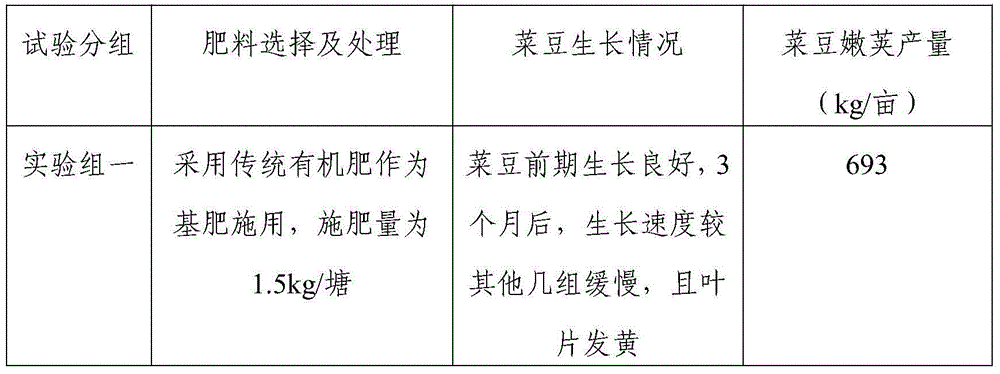

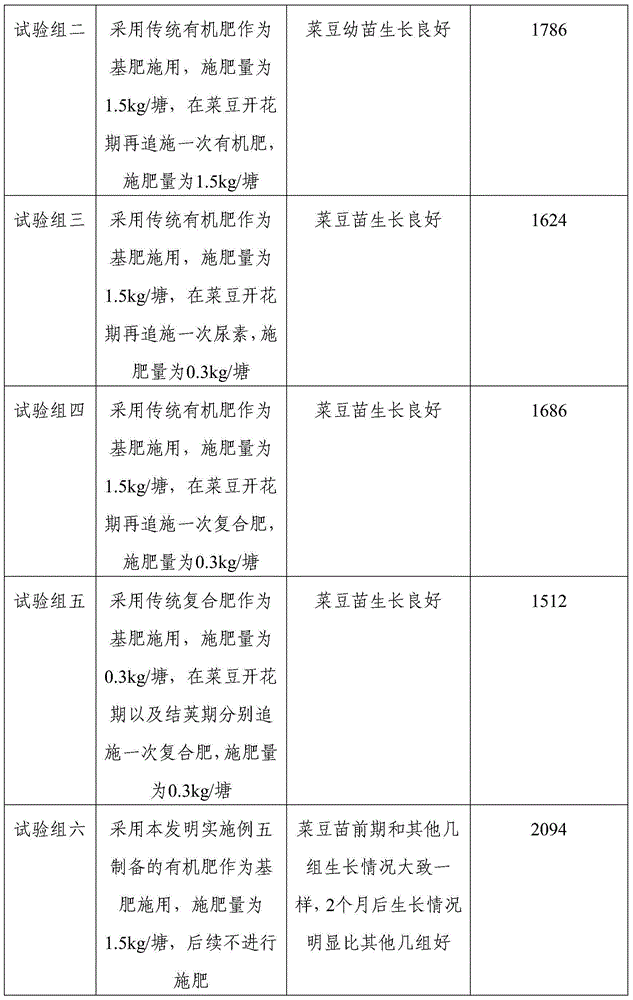

Examples

Embodiment 1

[0030] raw material:

[0031] Vermicompost 10kg, cow dung 40kg, pig manure 20kg, chicken manure 10kg, oil 80kg, starter 0.3kg, salt hornwort 20kg, moss 15kg, ghost needle grass 20kg, wormwood 20kg, potassium nitrate 15kg, urea formaldehyde 6kg, Potassium dihydrogen phosphate 4kg and potassium sulfate 12kg.

[0032] Preparation:

[0033] (1) Pretreatment of raw materials: First, boil wormwood, moss, salt hornwort and ghost needle grass with hot water at 80°C for 20 minutes, then boil the wormwood, moss, salt hornwort and ghost needle grass at a temperature of 120 ℃ in the drying machine, and then crushed into 4mm in diameter and mixed evenly, the obtained mixed material was sent to the carbonization kiln, the temperature was raised to 140 ℃ and kept at a constant temperature for 3 hours, and then the temperature was raised to Keep at 600°C for 8 hours, and obtain semi-carbonized material after cooling;

[0034] (2) Fermentation: Send the semi-carbonized material obtained in ...

Embodiment 2

[0046] raw material:

[0047] Vermicompost 20kg, cow manure 60kg, pig manure 30kg, chicken manure 20kg, oil 100kg, starter 0.4kg, salt hornwort 30kg, moss 25kg, ghost needle grass 30kg, wormwood 30kg, potassium nitrate 25kg, urea formaldehyde 10kg, Potassium dihydrogen phosphate 8kg and potassium sulfate 18kg.

[0048] Preparation:

[0049] (1) Pretreatment of raw materials: First, boil wormwood, moss, salt hornwort and ghost needle grass with hot water at 100°C for 30 minutes, then boil the wormwood, moss, salt hornwort and ghost needle grass at a temperature of 140 ℃ drying machine, and then crushed into powders with a diameter of 10mm and mixed evenly, the obtained mixture was sent to the carbonization kiln, the temperature was raised to 160 ℃ and kept at a constant temperature for 4 hours, and then the temperature was raised to Keep at 700°C for 10 hours, and obtain semi-carbonized material after cooling;

[0050] (2) Fermentation: Send the semi-carbonized material obta...

Embodiment 3

[0062] raw material:

[0063] Vermicompost 12kg, cow dung 45kg, pig manure 22kg, chicken manure 12kg, oil 85kg, starter 0.3kg, salt hornwort 22kg, moss 17kg, ghost needle grass 22kg, wormwood 22kg, potassium nitrate 16kg, urea formaldehyde 7kg, Potassium dihydrogen phosphate 5kg and potassium sulfate 13kg.

[0064] Preparation:

[0065] (1) Raw material pretreatment: First, boil wormwood, moss, salt hornwort and ghost needle grass with hot water at 85°C for 22 minutes, then boil the wormwood, moss, salt hornwort and ghost needle grass at a temperature of 125 ℃ drying machine, and then crushed into powders with a diameter of 6mm and mixed evenly, the obtained mixture was sent to the carbonization kiln, the temperature was raised to 145 ℃ and kept at a constant temperature for 4 hours, and then the temperature was raised to Keep at 620°C for 9 hours, and obtain a semi-carbonized material after cooling;

[0066] (2) Fermentation: Send the semi-carbonized material obtained in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com