Flexible chitosan luminescent film with rare earth and method for preparing flexible chitosan luminescent film

A rare earth luminescent and luminescent thin film technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems such as being insoluble in water and conventional organic solvents, the preparation process of luminescent thin films is not environmentally friendly, and the application is limited. Fluorescence quenching, reducing the use of pharmaceuticals, and improving the effect of luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of a rare earth-containing flexible chitosan luminescent film, using the following steps:

[0025] 1) Take 1g of hectorite in a 100ml flask, add 15ml of double distilled water to dissolve, sonicate it to make it fully expand, and stir it with a glass rod until it is in a transparent gel state. The stirring time is about 30min, and then add 10ml of 0.1mol / LEuCl 3 ·6H 2 O ethanol solution, stirred in an oil bath at 80°C for 24h. After centrifugation, ultrasonic washing, and finally drying in an oven at 50°C for 24 hours, the ion-exchanged water-soluble gel-state nanoclay was obtained, which was designated as LA-Eu. Among them, the rare earth ion Eu 3+ The mass percent content is 6.3%.

[0026] 2) Take 0.29g (1.308mmol) α-thienoyltrifluoroacetone (TTA) in a 100ml flask (the molar number of Ln ions is excessive relative to TTA), add 10ml of absolute ethanol to dissolve, and then dissolve the gel obtained in step 1) LA-Eu in the state was added to ...

Embodiment 2

[0030] A preparation method of a rare earth-containing flexible chitosan luminescent film, using the following steps:

[0031] 1) same as step 1) of embodiment 1;

[0032] 2) same as step 2) of embodiment 1;

[0033] 3) Dissolve 0.161g of carboxyimidazole ionic liquid V in 8.4ml of water, add 0.329g of chitosan, and sonicate until it is completely dissolved; take 0.13g of LA-EuTTA and disperse it into 8.4ml of water, mix well, sonicate for 30min, and use dripping Add it dropwise to a glass slide, put it in an oven at 30°C, and dry it slowly to obtain a light, uniform, and transparent luminescent film II. Among them, carboxyimidazole ionic liquid: chitosan = 1: 2, rare earth luminescent material: ionic liquid bond chain chitosan derivative = 1: 3.8. Add 16 mg of water-soluble gel-state rare earth luminescent material, 39 mg of chitosan, and 19 mg of carboxyimidazole ionic liquid per 1 ml of water.

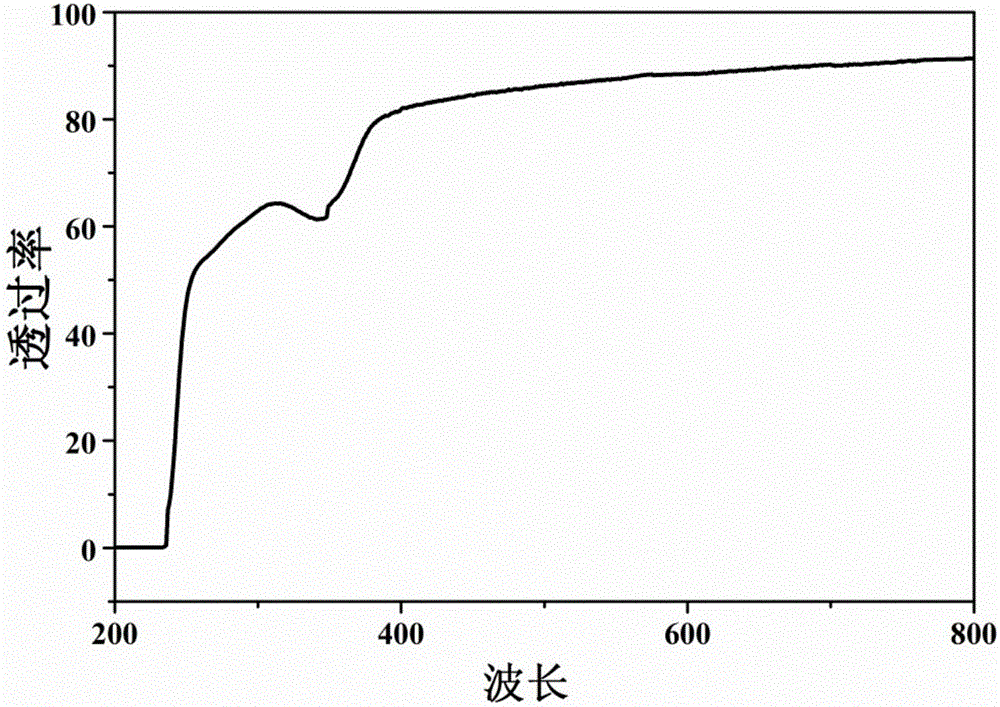

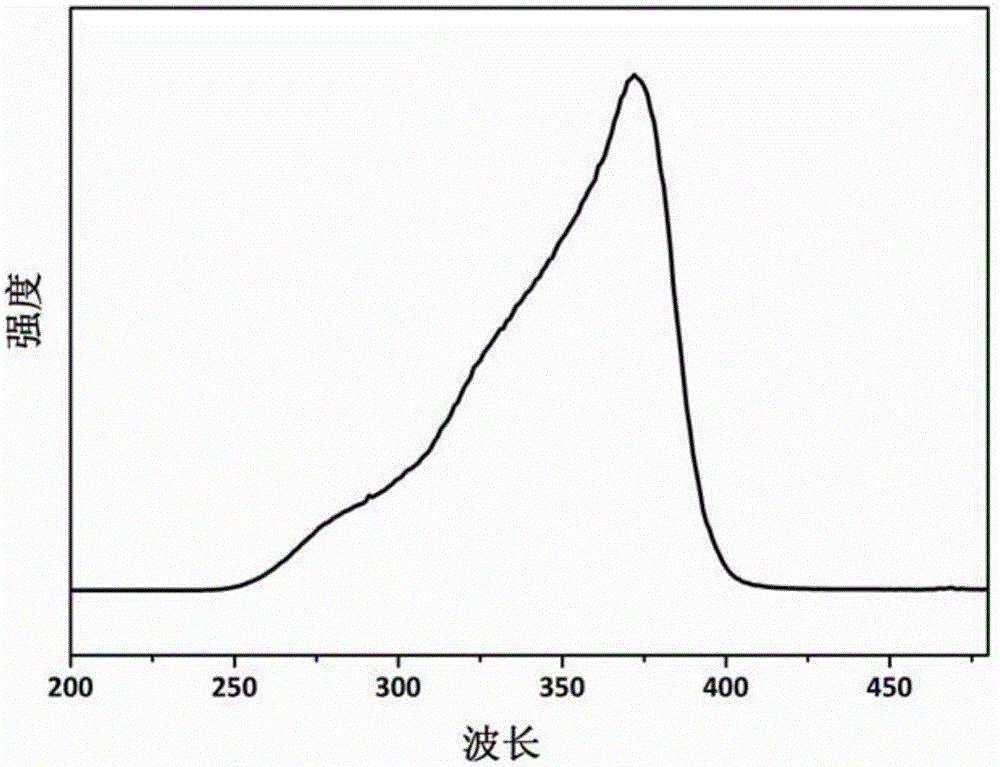

[0034] The above-mentioned luminescent film II is the same as the luminescen...

Embodiment 3

[0036] A preparation method of a rare earth-containing flexible chitosan luminescent film, using the following steps:

[0037] 1) same as step 1) of embodiment 1;

[0038] 2) same as step 2) of embodiment 1;

[0039] 3) Dissolve 0.073g of carboxyimidazole ionic liquid II in 3.8ml of water, add 0.148g of chitosan, and sonicate until it is completely dissolved; take 0.045g of LA-EuTTA and disperse it into 3.8ml of water, mix well, ultrasonicate for 30min, and use drop Add it dropwise to a glass slide, put it in an oven at 30°C, and dry it slowly to obtain a light, uniform, and transparent flexible chitosan luminescent film III. Among them, carboxyimidazole ionic liquid: chitosan = 1: 2, rare earth luminescent material: ionic liquid bond chain chitosan derivative = 1: 4.9. Add 12 mg of water-soluble gel-state rare-earth luminescent material, 39 mg of chitosan, and 16 mg of carboxyimidazole ionic liquid per 1 ml of water.

[0040] The luminescent film III, like the luminescent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com