Method for preparing silvery white chemical conversion coating on brass surface

A chemical conversion film, silver-white technology, applied in the direction of metal material coating process, etc., can solve the problems of poor film adhesion, weak corrosion resistance, easy discoloration, etc., and achieves good adhesion, low cost, and acid corrosion resistance. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

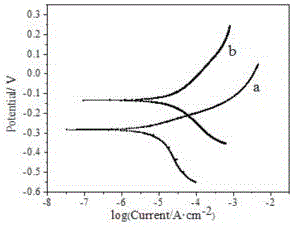

Image

Examples

Embodiment 1

[0038] 1) Weigh 0.5000g of benzotriazole and add 20mL of ethanol to dissolve, then add 20.0000g of tartaric acid to dissolve in water, then add 5.0000g of antimony trioxide, then add 200mL of hydrochloric acid to completely dissolve the precipitate, add water to make up to 1000mL;

[0039] 2) Weigh 50g of sodium hydroxide, 20g of sodium carbonate, 50g of sodium phosphate, and 8g of sodium silicate and dissolve them in water in turn, add water to make up to 1000mL;

[0040] 3) Measure 700mL of hydrogen peroxide, then add 150g of ethylene glycol, 40g of concentrated sulfuric acid, 2mL of OP-10, add water to 1000mL;

[0041] 4) Slowly add 10mL of concentrated sulfuric acid into water, cool to room temperature, add water to make up to 1000mL;

[0042] 5) Brass surface pretreatment: for the substrate at 70 0 Degreasing under C conditions, the duration is 5 minutes; polishing is performed at room temperature, the duration is 30s; activation treatment is performed at room temperatur...

Embodiment 2

[0052] 1) Weigh 0.8000g of benzotriazole and add 25mL of ethanol to dissolve, then add 26.0000g of tartaric acid to dissolve in water, then add 7.0000g of antimony trioxide, then add 240mL of hydrochloric acid to completely dissolve the precipitate, add water to make up to 1000mL;

[0053] 2) Weigh 40g of sodium hydroxide, 15g of sodium carbonate, 40g of sodium phosphate, and 5g of sodium silicate and dissolve them in water in turn, add water to make up to 1000mL;

[0054] 3) Measure 600mL of hydrogen peroxide, then add 120g of ethylene glycol, 30g of concentrated sulfuric acid, 1mL of OP-10, add water to 1000mL;

[0055] 4) Slowly add 10mL of concentrated sulfuric acid into water, cool to room temperature, add water to make up to 1000mL;

[0056] 5) Brass surface pretreatment: for the substrate at 60 0 Degreasing under C conditions for 3 minutes; polishing at room temperature for 30 s; activation at room temperature for 10 s; a water washing process interspersed between each...

Embodiment 3

[0066] 1) Weigh 1.0000g of benzotriazole and add 30mL of ethanol to dissolve, then add 30.0000g of tartaric acid to dissolve in water, then add 10.0000g of antimony trioxide, then add 300mL of hydrochloric acid to completely dissolve the precipitate, add water to make up to 1000mL;

[0067] 2) Weigh 43g of sodium hydroxide, 17g of sodium carbonate, 45g of sodium phosphate, and 7g of sodium silicate, dissolve them in water in turn, add water to make up to 1000mL;

[0068] 3) Measure 660mL of hydrogen peroxide, then add 135g of ethylene glycol, 35g of concentrated sulfuric acid, 3mL of OP-10, add water to 1000mL;

[0069] 4) Slowly add 10mL of concentrated sulfuric acid into water, cool to room temperature, add water to make up to 1000mL;

[0070] 5) Brass surface pre-treatment: for the substrate at 65 0 Degreasing under C conditions for 4 minutes; polishing at room temperature for 30 s; activation at room temperature for 15 s; a water washing process interspersed between each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com