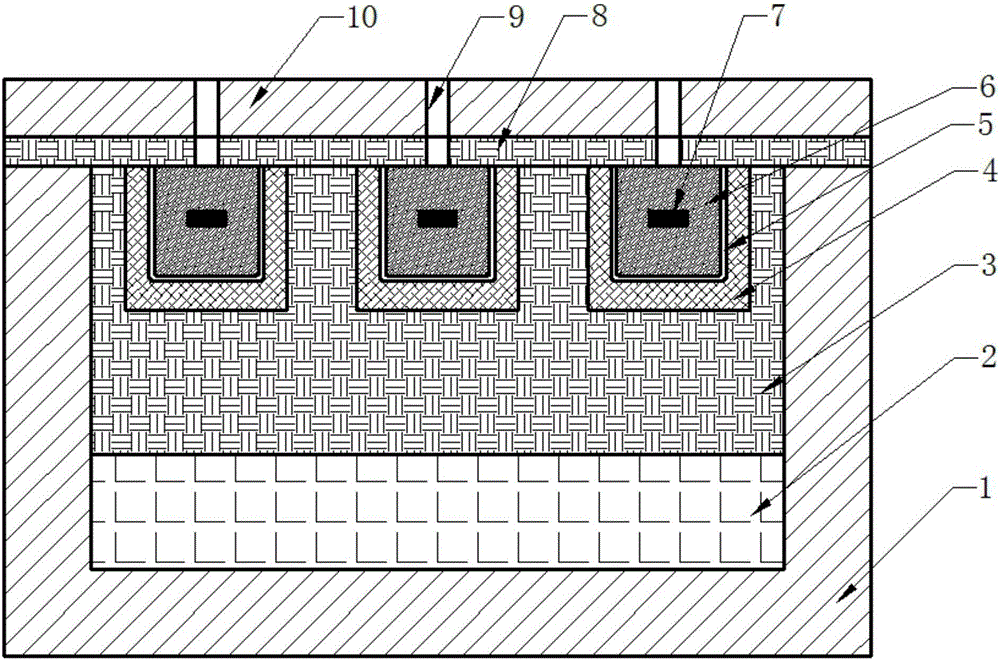

Multicavity microwave sintering insulation device for ceramic tool

A technology of microwave sintering and ceramic knives, which is applied in the direction of furnaces, furnace types, lighting and heating equipment, etc., can solve the problems of low production efficiency of knives materials, too fast temperature loss of crucibles, etc., and achieve good interchangeability, fast heating rate, Avoid the effects of oxidation reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Sintering of alumina-based ceramic knives. Three sintered samples of the same quality were placed in a crucible, placed in a buried powder composed of silicon carbide and graphite mixed powder, and covered with an aluminum silicate non-asbestos cover and a mullite cover. Place the heat preservation device in the cavity of the microwave sintering furnace, adjust the position so that the infrared rays emitted by the infrared thermometer hit the buried powder in the middle cavity, then close the furnace door, vacuumize, and turn on the microwave switch for sintering. The low temperature section is raised to 800°C at a speed of 20°C / min and kept for 5 minutes, then raised to 1700°C at a speed of 30-40°C / min, kept for 10 minutes, and then cooled with the furnace. Alumina-based ceramic tool materials were obtained, and the densities of the materials obtained by the three cavities were 99.2±0.2%, 99.3±0.3% and 99.1±0.1%, which can meet the requirements for the use of tool mate...

Embodiment 2

[0026] Sintering of silicon nitride based ceramic cutting tools. Three sintered samples of the same quality were placed in a crucible, placed in a buried powder composed of silicon carbide and boron nitride mixed powder, and covered with an aluminum silicate non-asbestos cover and a mullite cover. Place the heat preservation device in the cavity of the microwave sintering furnace, adjust the position so that the infrared rays emitted by the infrared thermometer hit the buried powder in the middle cavity, then close the furnace door, vacuumize, and turn on the microwave switch for sintering. At a speed of 30-40°C / min, the temperature is raised to 1800°C at a uniform speed, kept for 10 minutes, and then cooled with the furnace. A silicon nitride-based ceramic tool was obtained, and the densities of the materials obtained in the three cavities were 96.4±0.3%, 96.3±0.2% and 96.1±0.1%, respectively, and the Vickers hardness was 13.7±0.6GPa, 13.8±0.4GPa and 13.7±0.5GPa, the fractur...

Embodiment 3

[0028] Sintering of titanium carbonitride-based ceramic tools. Three sintered samples of the same quality were placed in a crucible, placed in a buried powder composed of silicon carbide and graphite mixed powder, and covered with an aluminum silicate non-asbestos cover and a mullite cover. Place the heat preservation device in the cavity of the microwave sintering furnace, adjust the position so that the infrared rays emitted by the infrared thermometer hit the buried powder in the middle cavity, then close the furnace door, vacuumize, and turn on the microwave switch for sintering. At a speed of 30-50°C / min, the temperature was raised to 1550°C at a uniform speed, kept for 10 minutes, and then cooled with the furnace. Titanium carbonitride-based ceramic tool materials were obtained, and the densities of the materials obtained in the three cavities were 98.1±0.2%, 98.3±0.1% and 98.2±0.3%, which can meet the requirements of tool materials. The entire sintering process Last fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com