Silver-doped copper zinc tin sulfur selenium light absorption layer film material and application thereof in solar cell

A copper-zinc-tin-sulfur-selenium, solar cell technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve problems such as narrow pure phase stable region, achieve the effect of less solvent usage, low requirements, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

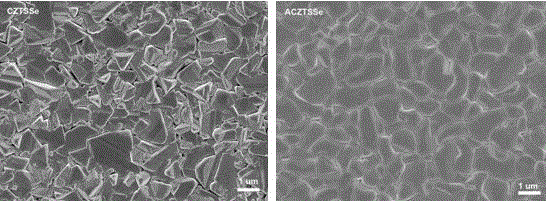

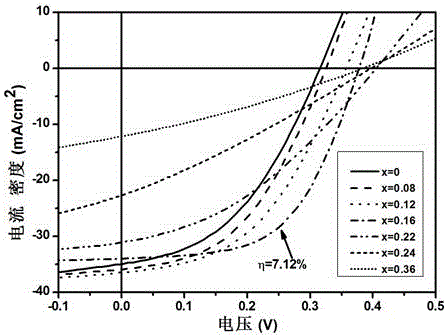

[0034] (1) Add 0.1 mol / L copper acetate, 0.05 mol / L anhydrous stannous chloride, 0.06 mol / L zinc acetate and 2 mol / L thiourea to 20 mL dimethyl sulfoxide (DMSO), stir until completely dissolved to form a transparent and clear CZTS precursor solution; (2) Spin-coat the CZTS sol precursor onto the cleaned molybdenum-coated glass substrate with a homogenizer, then dry it on a heating plate at 400°C for 5 minutes, and spin-coat repeatedly 11 times; (3) After the spin coating is completed, the sample is placed in a rapid heating furnace for selenization at 550 °C for 10 minutes, the heating rate is 10 °C / s, and the temperature is naturally lowered. During the annealing process, the protective gas N 2 , with a flow rate of 15 mL / min, an undoped ACZTSSe film with a thickness of about 1.5 μm can be obtained (as shown in the attached figure 1shown). (4) Chemical bath deposition of CdS buffer layer (~30 nm) at 65 ℃. (5) The intrinsic ZnO window layer (~30 nm) was prepared by radio fre...

Embodiment 2

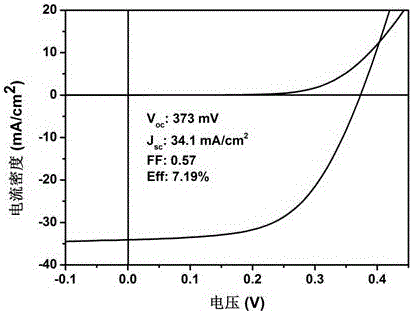

[0037] (1) Add 0.095 mol / L copper acetate, 0.005 mol / L silver nitrate, 0.05 mol / L anhydrous stannous chloride, 0.06 mol / L zinc acetate and 2 mol / L thiourea to 20 mL DMSO, stir until completely dissolved to form a silver-doped CZTS solution; (2) Spin-coat the ACZTS sol precursor onto the cleaned molybdenum-coated glass substrate using a homogenizer, then dry it on a heating plate at 400 °C for 5 minutes, and spin-coat repeatedly for 11 (3) After the spin coating is completed, the sample is placed in a rapid heating furnace for selenization at 550 °C for 10 minutes, the heating rate is 10 °C / s, and the temperature is naturally lowered. During the annealing process, the protective gas N 2 , with a flow rate of 15mL / min, an ACZTSSe film with a thickness of about 1.5 μm can be obtained. (4) Chemical bath deposition of CdS buffer layer (~30 nm) at 65 ℃. (5) The intrinsic ZnO window layer (~30 nm) was prepared by radio frequency magnetron sputtering. (6) DC magnetron sputtering ITO...

Embodiment 3

[0040] (1) Add 0.085 mol / L copper acetate, 0.015 mol / L silver nitrate, 0.05 mol / L anhydrous stannous chloride, 0.06 mol / L zinc acetate and 2 mol / L thiourea to 20 mL DMSO, Stir until completely dissolved to form a silver-doped CZTS solution; (2) Spin-coat the ACZTS sol precursor onto the cleaned molybdenum-coated glass substrate using a homogenizer, then dry it on a heating plate at 400 °C for 5 minutes, and spin-coat repeatedly 11 times; (3) After the spin coating is completed, the sample is placed in a rapid heating furnace for selenization at 550 °C for 10 minutes, the heating rate is 10 °C / s, and the temperature is naturally lowered. During the annealing process, the protective gas N 2 , with a flow rate of 15mL / min, an ACZTSSe film with a thickness of about 1.5 μm can be obtained. figure 1 shown). (4) Chemical bath deposition of CdS buffer layer (~30 nm) at 65 ℃. (5) The intrinsic ZnO window layer (~30 nm) was prepared by radio frequency magnetron sputtering. (6) DC mag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com