Nitrogen-doped carbonized bacterial cellulose loaded nano-platinum electrode material and preparation method thereof

A technology of bacterial cellulose and bacterial cellulose membrane is applied in the field of preparation of nitrogen-doped carbonized bacterial cellulose-loaded nano-platinum electrode materials, which can solve the problems of complex preparation process, volatile, expensive equipment, etc., and increase the number of active sites. , the effect of increasing the electrical conductivity and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

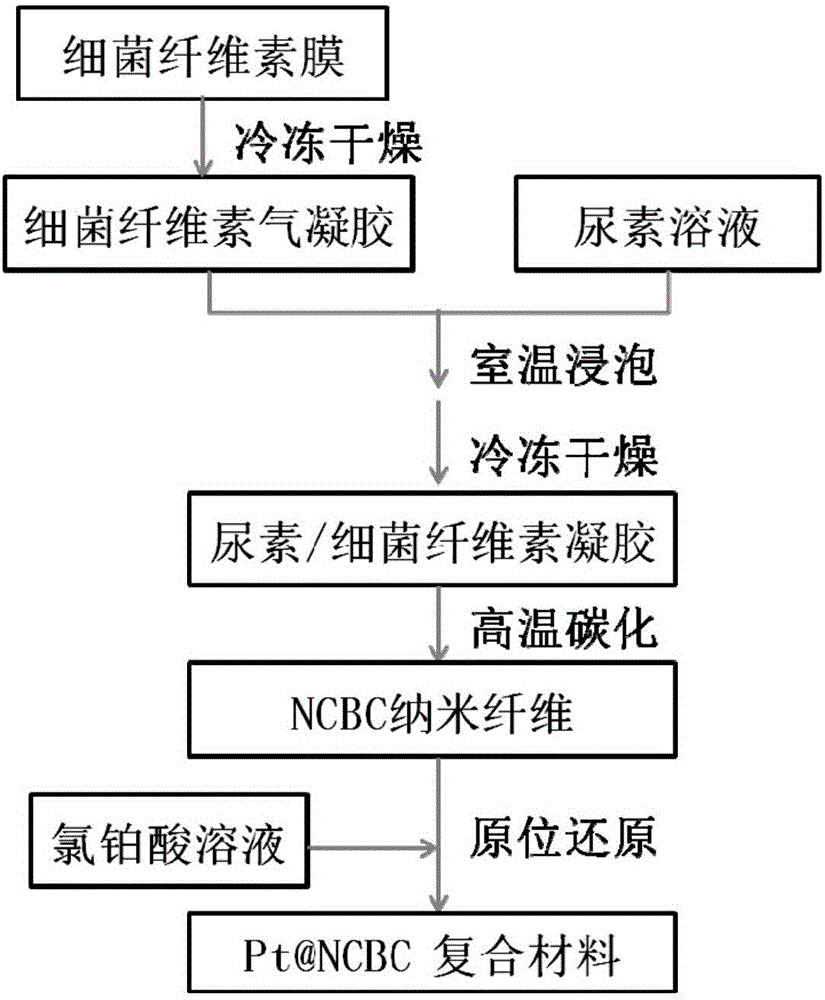

[0026] A kind of preparation method of nitrogen-doped carbonized bacterial cellulose supported nano-platinum electrode material of the present invention, the preparation flow chart is as follows figure 1 shown, including the following steps:

[0027] In the first step, the bacterial cellulose fermented by Acetobacter xylinum is pretreated to obtain a clean bacterial cellulose film, and the bacterial cellulose aerogel is obtained after freeze-drying;

[0028] The second step is to divide the airgel, soak it in urea solution, ultrasonically make the nitrogen source urea fully adsorbed into the bacterial cellulose, and let it stand for 20-24 hours; take out the urea / bacterial cellulose gel and freeze-dry it;

[0029] The third step is to heat the freeze-dried urea / bacterial cellulose gel to 600°C-1000°C for 2 hours, and obtain nitrogen-doped carbonized bacterial cellulose nanofibers after high-temperature carbonization;

[0030] The fourth step is to disperse the obtained nitrog...

Embodiment 1

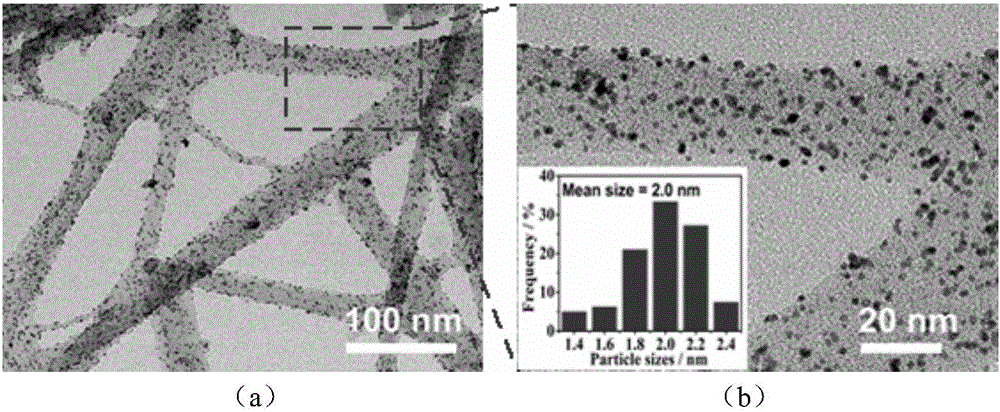

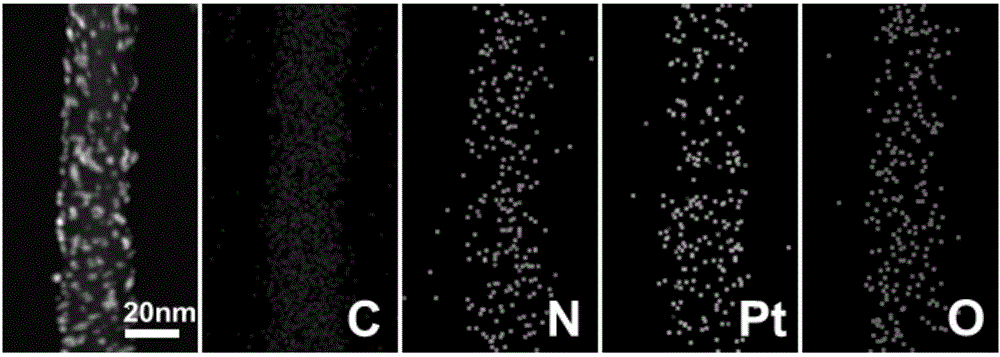

[0032] Heat the bacterial cellulose film obtained by the static fermentation of Acetobacter xylinum with 0.3% NaOH at 80°C for 3 hours, wash it with tap water until it becomes neutral; cut it into small pieces with a regular size of 2cm×2cm with scissors, place them in a freeze dryer and dry them for 24 hours. Take out and soak in 2.5% urea solution, ultrasonic for 30 minutes, then stand for 24 hours, and freeze-dry for 12 hours to obtain urea / bacterial cellulose airgel. Place in a tubular muffle furnace, raise the temperature to 800°C at a heating rate of 2°C / min, and keep the temperature for 2 hours to obtain nitrogen-doped carbonized bacterial cellulose. Take 20 mg of the product, disperse it in 80 mL of ethylene glycol solution, ultrasonicate for 30 min, then add 540 μL of chloroplatinic acid aqueous solution to adjust the pH to 9, transfer the sample to a three-neck flask, heat to 90°C and reflux for 3 h. Centrifuge the reaction product at a speed of 10000r / min for 15min,...

Embodiment 2

[0035]Heat the bacterial cellulose film obtained by the static fermentation of Acetobacter xylinum with 0.2% NaOH at 80°C for 3 hours, wash it with tap water until it becomes neutral; cut it into small pieces with a regular size of 2cm×2cm with scissors, place it in a freeze dryer and dry it for 24 hours, Take it out and soak it in 2.0% urea solution, sonicate for 30 minutes, then let it stand for 24 hours, and freeze-dry for 12 hours to obtain a white airgel. Place in a tubular muffle furnace, raise the temperature to 800°C at a heating rate of 2°C / min, and keep the temperature for 2 hours to obtain nitrogen-doped carbonized bacterial cellulose. Take 20 mg of the product, disperse it in 80 mL of ethylene glycol solution, ultrasonicate for 30 min, then add 540 μL of chloroplatinic acid aqueous solution to adjust the pH to 9, transfer the sample to a three-neck flask, heat to 90°C and reflux for 3 h. Centrifuge the reaction product at a speed of 10000r / min for 15min, pour off t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com