A kind of assembly system and preparation method of pegma-modified moox and thermosensitive pnipam microgel

A microgel, temperature-sensitive technology, which is applied in the directions of non-active ingredient medical preparations, medical preparations containing active ingredients, drug combinations, etc., can solve the problems of difficult target release of drugs, toxic and side effects, and achieve low cost. , easy operation, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

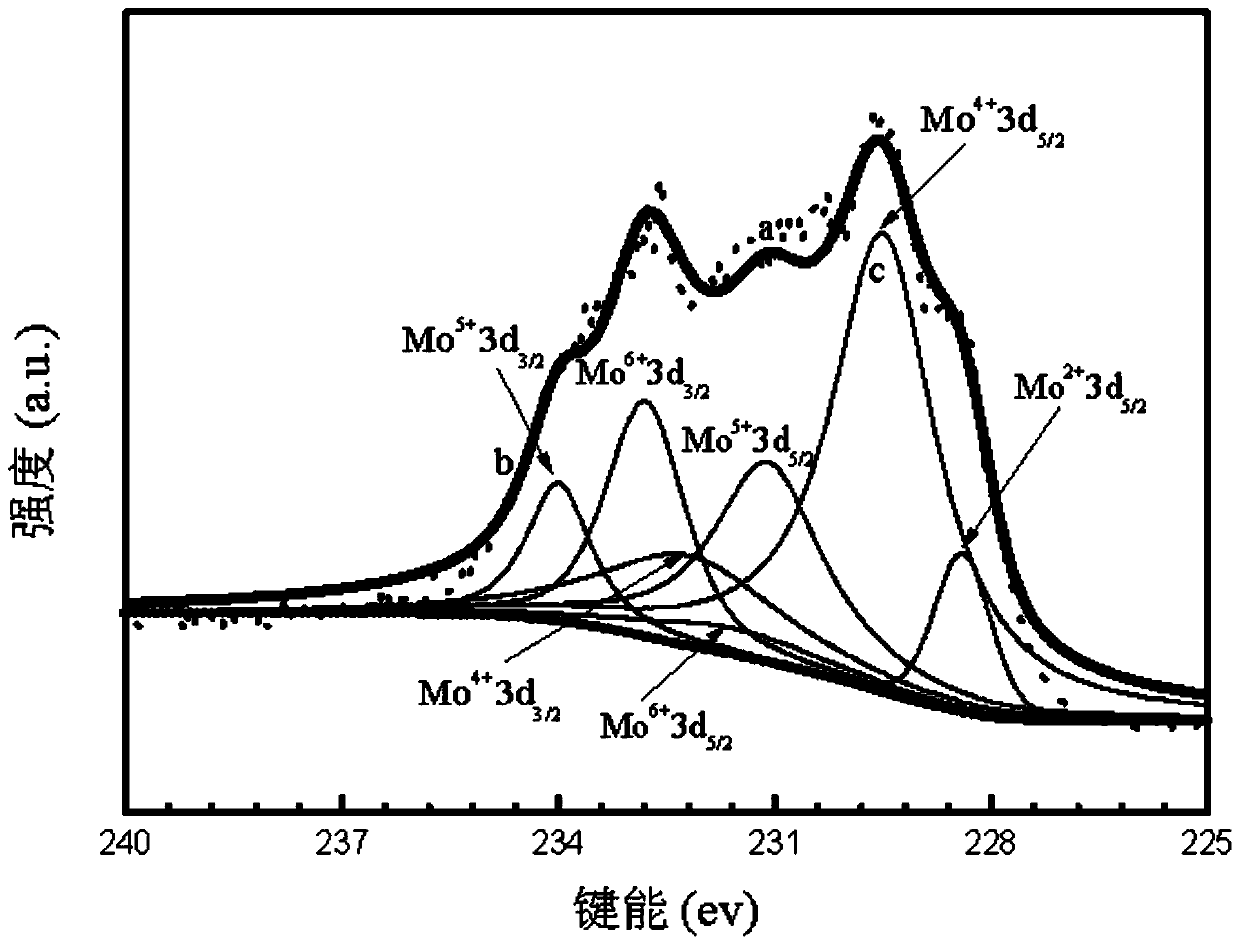

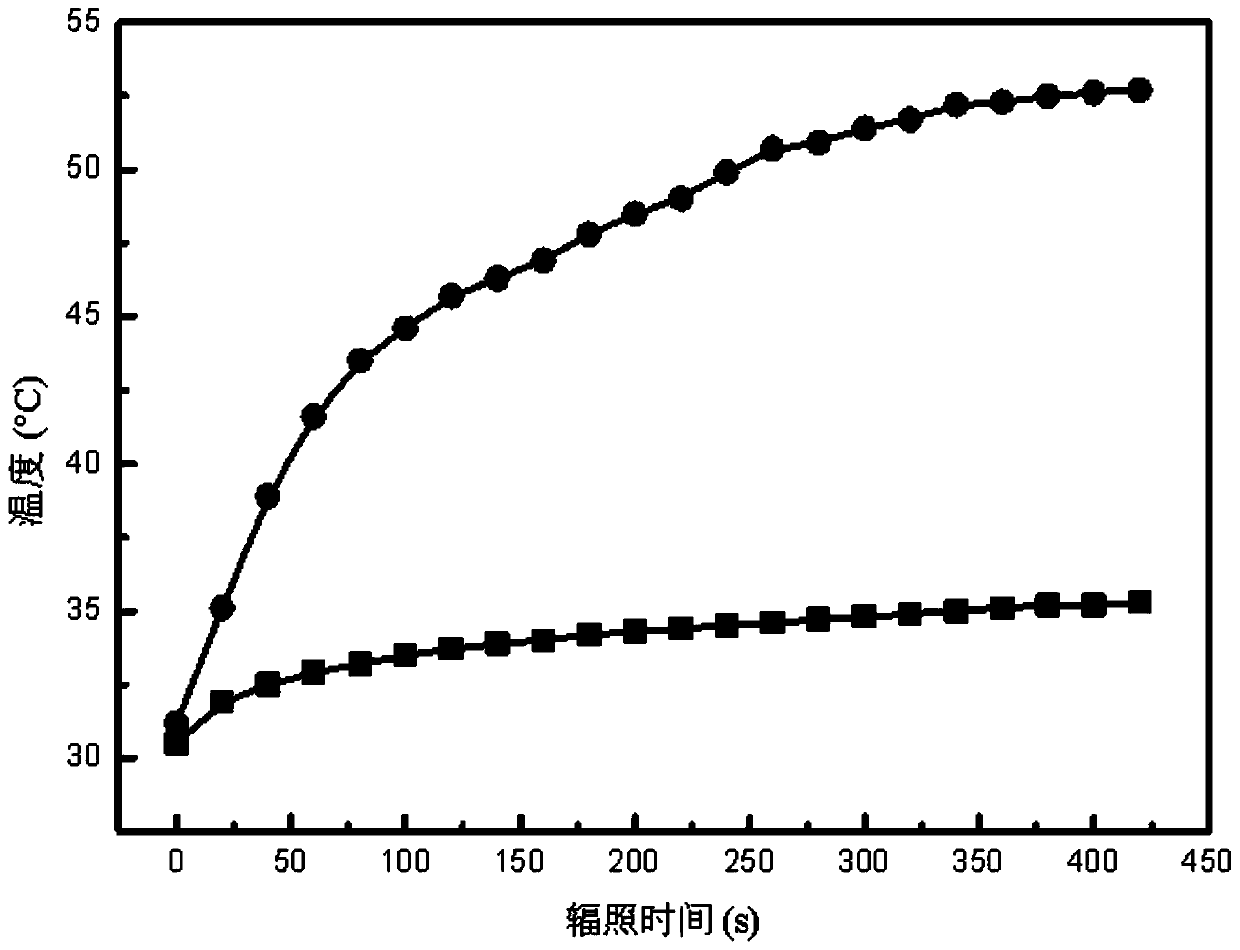

[0027] Specific Embodiment 1: This embodiment is an assembly system of PEGMa-modified MoOx and temperature-sensitive PNIPAM microgel, the chemical formula of which is PEGMa-MoOx / P(NIPAM-co-MAA).

specific Embodiment approach 2

[0028] Specific embodiment two: In this embodiment, a method for preparing an assembly system of PEGMa modified MoOx and thermosensitive PNIPAM microgel is carried out according to the following steps:

[0029] 1. Dissolve 0.08-0.09g of ammonium molybdate in 15-25ml of deionized water under stirring;

[0030] 2. Dissolve 0.4-0.6g methacrylate in 10-15ml absolute ethanol solution;

[0031] 3. Mix the solutions obtained in step 1 and step 2, and then react at a constant temperature of 160°C for 10 to 14 hours by hydrothermal method, centrifuge the precipitate, wash and dry to obtain modified molybdenum oxide PEGMa-MoOx;

[0032] 4. Dissolve the above-mentioned PEGMa-MoOx in a beaker filled with 100ml of deionized water, stir for 30min, transfer to a 250ml round bottom flask, then add 1.5-2.0g of N-isopropylacrylamide, 82-328μL of methyl Acrylic acid, 0.05~0.07g N,N-methylene bisacrylamide and 0.05~0.06g sodium lauryl sulfate and mix well, heat up to 70°C at a heating rate of 1~...

specific Embodiment approach 3

[0036] Specific embodiment three: this embodiment is different from specific embodiment two in that: in step one, 0.0865 g of ammonium molybdate is dissolved in 20 ml of deionized water under stirring conditions. Other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com