Self-assembled super-molecular polymer nano-filtration membrane based on graphene and preparation method thereof

A supramolecular polymer, self-assembly technology, applied in chemical instruments and methods, membrane, membrane technology, etc., to achieve the effect of good controllability, multiple added value, and expansion of assembled materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

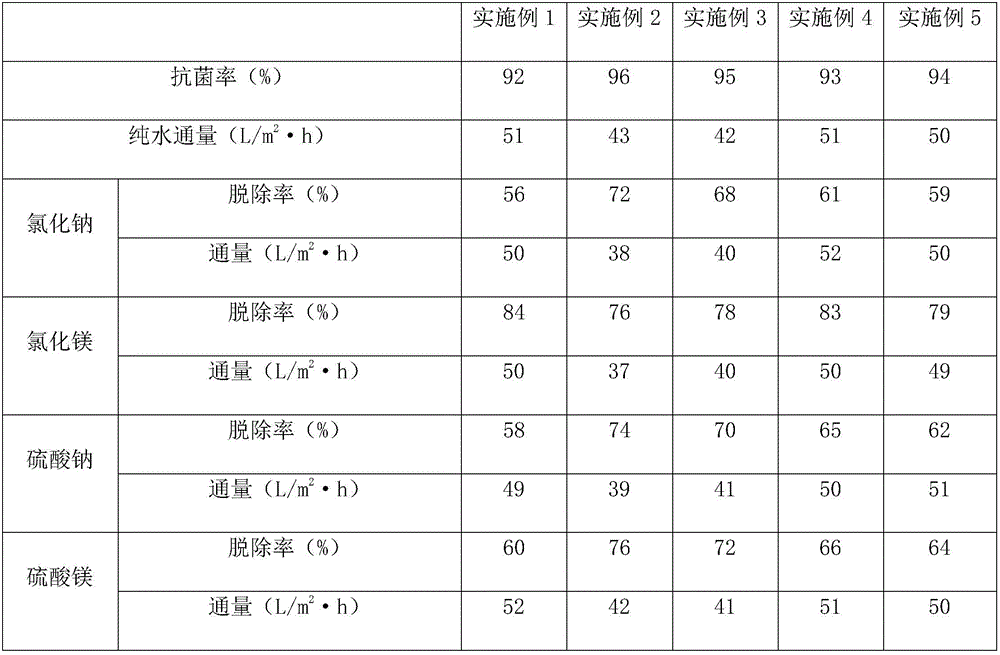

Examples

Embodiment 1

[0030] (1) Add polyethyleneimine to deionized water, stir fully, add sodium chloride, and stir evenly to obtain a covalent cationic polyelectrolyte solution with a mass fraction of 0.2%, wherein the concentration of sodium chloride is 0.5M, and the pH value is 2.5.

[0031] (2) Mix the 1mmol / L zinc ion transition metal ion solution and the bis-leidyl oxalic acid solution, wherein the molar ratio of the transition metal ion to the bis-leidyl oxalic acid is 1:1, and adjust the pH value of the mixed system to 5 with a buffer , fully stirred to obtain a supramolecular polymer solution.

[0032] (3) The alkali-modified polyacrylonitrile ultrafiltration membrane with a molecular weight cut-off of 30,000 is used as the base membrane, and the base membrane is fixed in a container with a porous support layer, with the membrane facing up, and then a total of valent cation polyelectrolyte solution, pressurized assembly at 0.1 MPa for 5 min, and fully washed with deionized water for 1 mi...

Embodiment 2

[0037] (1) Add polyvinylamine into deionized water, stir fully, add sodium chloride, stir evenly to obtain a covalent cationic polyelectrolyte solution with a mass fraction of 0.5%, wherein the concentration of sodium chloride is 0.5M, and the pH value is 3 .

[0038] (2) Mix 3mmol / L copper ions and cobalt ions transition metal ion solution and bisleidyl oxalic acid solution, wherein the molar ratio of transition metal ions to bisleidyl oxalic acid is 1:2, adjust the pH of the mixed system with buffer The value is 6, and the supramolecular polymer solution is obtained by stirring thoroughly.

[0039] (3) The sulfonated polyethersulfone ultrafiltration membrane with a molecular weight cut-off of 50,000 is used as the base membrane, and the base membrane is fixed in a container with a porous support layer, with the membrane facing up, and then covalent cations are added to the container The polyelectrolyte solution was pressurized and assembled at 0.8 MPa for 5 minutes, and ful...

Embodiment 3

[0044] (1) polyallyl ammonium chloride is added in deionized water, fully stirred, sodium chloride is added, stirred evenly, and the covalent cationic polyelectrolyte solution that obtains mass fraction is 0.3%, wherein the concentration of sodium chloride is 0.5M, The pH is 2.7.

[0045] (2) The iron ion of 3.5mmol / L and the lanthanum ion transition metal ion solution and the bis-leidyl oxalic acid solution are mixed, wherein the mol ratio of the transition metal ion and the bis-leidyl oxalic acid is 1:1.5, regulates the mixed system with buffer The pH value is 5.4, and the supramolecular polymer solution is obtained by thorough stirring.

[0046] (3) The alkali-modified polyacrylonitrile ultrafiltration membrane with a molecular weight cut-off of 40,000 is used as the base membrane, and the base membrane is fixed in a container with a porous support layer with the membrane facing up, and then a total of Valence cationic polyelectrolyte solution, pressurized assembly at 0.5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com