SiO2@TiO2 nuclear shell structure with stable dispersion and controllable photocatalysis, preparing method and application thereof

A technology with photocatalytic activity and core-shell structure, applied in chemical instruments and methods, chemical/physical processes, light water/sewage treatment, etc., can solve poor stability and weather resistance, affect product dispersibility, product yellowing and shedding, etc. problem, to achieve the effects of stable dispersion, controllable photocatalytic activity, uniform shell thickness and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

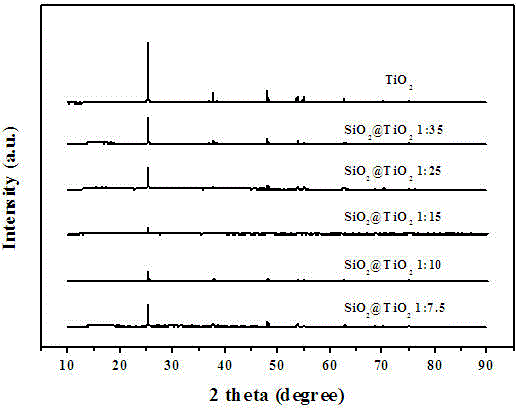

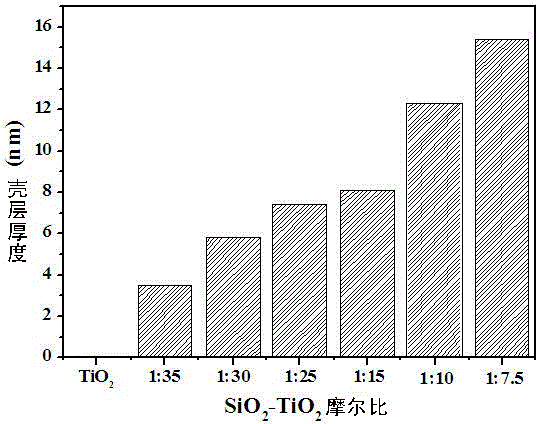

[0024] A stable dispersed SiO with controllable photocatalytic activity 2 @TiO 2 The macro-preparation method of the core-shell structure, the steps are as follows:

[0025] (1) 100 g anatase TiO 2 Add distilled water to form a suspension with a concentration of 100 g / L, add 0.3 g of (NaPO 3 ) 6 As a dispersant, stir for 30 min;

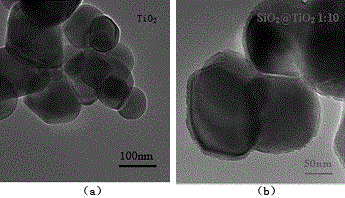

[0026] (2) Transfer the dispersed sample in step (1) to the reactor, add 0.5 mol / L sodium silicate solution and 1.5 mol / L Sulfuric acid solution, the molar ratio of sodium silicate to titanium dioxide is 1:10, the pH of the reaction system is 9.5, the dropping rate of sodium silicate solution is 1.5 mL / min, after reacting for 2 hours, aging at room temperature for 3 hours, washing with distilled water until the conductivity Less than 20 mS / m, get a certain solid-liquid ratio of SiO 2 @TiO 2 suspension storage;

[0027] (3) or the SiO of step (2) 2 @TiO 2 The suspension was dried at 105 °C for 24 h, ground into powder for storage, and @ mean...

Embodiment 2

[0029] A stable dispersed SiO with controllable photocatalytic activity 2 @TiO 2 The macro-preparation method of the core-shell structure, the steps are as follows:

[0030] (1) 100 g anatase TiO 2 Add distilled water to make a suspension with a concentration of 300g / L, add 0.5g of (NaPO 3 ) 6 As a dispersant, stir for 1h;

[0031] (2) Transfer the dispersed sample in step (1) to the reactor, add 0.5mol / L sodium silicate solution and 0.5mol / L Sulfuric acid solution, the molar ratio of sodium silicate to titanium dioxide is 1:7.5, the pH of the reaction system is 8, the dropping rate of sodium silicate solution is 1.5 mL / min, after reacting for 1 h, aging at room temperature for 2 h, washing with distilled water until the conductivity The rate is less than 20 mS / m, and a certain solid-liquid ratio of SiO 2 @TiO 2 suspension storage;

[0032] (3) or the SiO of step (2) 2 @TiO 2 The suspension was dried at 105 °C for 24 h, ground into powder for storage, and @ means coa...

Embodiment 3

[0034] A stable dispersed SiO with controllable photocatalytic activity 2 @TiO 2 The macro-preparation method of the core-shell structure, the steps are as follows:

[0035](1) 100 g anatase TiO 2 Add distilled water to form a suspension with a concentration of 500g / L, add 0.1g of (NaPO 3 ) 6 As a dispersant, stir for 2h;

[0036] (2) Transfer the dispersed sample in step (1) to the reactor, add 0.5 mol / L sodium silicate solution and 1 mol / L sulfuric acid to the reactor at the same time in a water bath at 100 °C and a stirring rate of 500 r / min solution, the molar ratio of sodium silicate to titanium dioxide is 1:15, the pH of the reaction system is 10, the dropping rate of the sodium silicate solution is 1.5 mL / min, after reacting for 3 h, aging at room temperature for 1.5 h, washing with distilled water until the conductivity Less than 20 mS / m, get a certain solid-liquid ratio of SiO 2 @TiO 2 suspension storage;

[0037] (3) or the SiO of step (2) 2 @TiO 2 The susp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com