Environment-friendly coated slow-release fertilizer for wheat

An environmentally friendly, coated and slow-release technology, which is applied in the direction of layered/coated fertilizers, nitrogen fertilizers, and potassium fertilizers, can solve the problems of difficult degradation of coated materials, restrictions on large-scale use, and expensive coated fertilizers. Absorb, improve soil nutrient status, prevent premature aging and defertilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

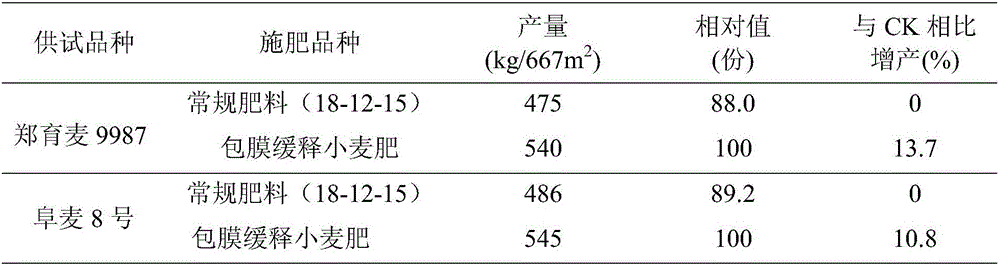

Image

Examples

Embodiment 1

[0026] In this embodiment, an environment-friendly coated slow-release wheat fertilizer comprises the following raw materials by weight percentage: 15% urea, 34% monoammonium phosphate, 16% potassium chloride, 12% ammonium phosphorus nitrate, and 1% ammonium sulfate , potassium sulfate 3%, organic fertilizer 5%, trace element fertilizer 5%, 2-chloro-6-trichloromethylpyridine 0.1%, modified cassava flour 6.9%, kaolin 2%;

[0027]Wherein, the preparation method of the modified cassava flour comprises: adding water to the cassava flour and raising the temperature to 50°C, stirring until a paste is formed, adding ferrous sulfate and stirring evenly, adding hydrogen peroxide with a content of 32% dropwise, and completing the dripping within 5 minutes. Add, stir evenly, then add 35% sodium hydroxide solution, adjust the pH to 10, stir and react at a constant temperature for 1 hour to obtain gelatinized cassava flour; add polyvinyl alcohol and stir evenly, heat up to 90°C, and keep wa...

Embodiment 2

[0034] In this embodiment, an environmentally friendly coated slow-release wheat fertilizer comprises the following raw materials by weight percentage: 22% urea, 26% monoammonium phosphate, 16% potassium chloride, 6% ammonium nitrate, and 5% ammonium sulfate , potassium sulfate 1%, organic fertilizer 15%, trace element fertilizer 2%, n-butyl thiophosphoric triamide 0.5%, modified cassava flour 4%, diatomaceous earth 2.5%;

[0035] Wherein, the preparation method of the modified cassava flour comprises: adding water to the cassava flour and raising the temperature to 55° C., stirring until a paste is formed, adding ferrous sulfate and stirring evenly, adding hydrogen peroxide with a content of 28% dropwise, and completing the dripping within 10 minutes. Add, stir evenly, then add 30% sodium hydroxide solution, adjust the pH to 12, stir and react at a constant temperature for 0.5h to obtain gelatinized cassava flour; add polyvinyl alcohol and stir evenly, heat up to 95°C, and kee...

Embodiment 3

[0042] In this embodiment, an environmentally friendly coated slow-release wheat fertilizer comprises the following raw materials by weight percentage: 15% urea, 26% monoammonium phosphate, 23% potassium chloride, 9% ammonium nitrate, and 3% ammonium sulfate , potassium sulfate 2%, organic fertilizer 6%, trace element fertilizer 3.5%, tetraclopyridine carboxylic acid 0.5%, modified cassava flour 10%, zeolite powder 2%;

[0043] Wherein, the preparation method of the modified cassava flour comprises: adding water to the cassava flour and raising the temperature to 53° C., stirring until a paste is formed, adding ferrous sulfate and stirring evenly, adding 30% hydrogen peroxide dropwise, and completing the dripping within 7 minutes. Add, stir evenly, then add sodium hydroxide solution with a content of 33%, adjust the pH to 11, stir and react at a constant temperature for 0.7h, and obtain gelatinized cassava flour; add polyvinyl alcohol and stir evenly, heat up to 92°C, and keep ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com