Preparation method for 2,3,3,3-tetrafluoropropene

A technology of tetrafluoropropene and pentafluoropropane, which is applied in the field of preparation of fluorine-containing olefins, can solve the problems of large equipment investment, long process route, and high separation cost, and achieve the effects of simplified process, short process flow and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

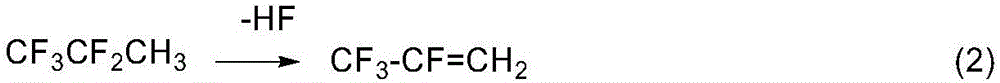

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of 1,1,1,2,2-pentafluoropropane

[0030] Replace the 2L stainless steel autoclave with nitrogen three times, then add 250g of tetrahydrofuran solution of methylmagnesium chloride (concentration of methylmagnesium chloride is 2mol / Kg) and 750g of tetrahydrofuran, and feed pentafluorochloroethane while stirring at 50°C 160g, continue to react for 3 hours after passing through. After the reaction is over, stop stirring, cool to 0°C, and filter to obtain 1,1,1,2,2-pentafluoropropane synthetic liquid, which has a purity of 99.5% after rectification and purification. Based on methylmagnesium chloride, the yield of 1,1,1,2,2-pentafluoropropane is 81.3%.

[0031] (2) Preparation of 2,3,3,3-tetrafluoropropene

[0032] The 1,1,1,2,2-pentafluoropropane obtained by the reaction in step (1) is passed through a potassium hydroxide solution with an excess mass percent concentration of 40% and a temperature of 70°C, and the gas phase product is collected and dried, C...

Embodiment 2

[0035] (1) Preparation of 1,1,1,2,2-pentafluoropropane

[0036] Replace the 2L stainless steel autoclave with nitrogen three times, then add 250g of tetrahydrofuran solution of methylmagnesium chloride (the concentration of methylmagnesium chloride is 2mol / Kg), 750g of tetrahydrofuran, and 200g of ethylene glycol dimethyl ether, and stir at 60°C 350 g of pentafluorochloroethane was passed through, and the reaction was continued for 1 hour after the passage was completed. After the reaction is finished, stop stirring, cool to 5°C, and filter to obtain 1,1,1,2,2-pentafluoropropane synthetic liquid, which has a purity of 99.5% after rectification and purification. Based on methylmagnesium chloride, the yield of 1,1,1,2,2-pentafluoropropane is 85.6%.

[0037] (2) Preparation of 2,3,3,3-tetrafluoropropene

[0038] The 1,1,1,2,2-pentafluoropropane obtained by the reaction in step (1) is passed through a sodium hydroxide solution with an excess mass percentage concentration of 60% ...

Embodiment 3

[0041] (1) Preparation of 1,1,1,2,2-pentafluoropropane

[0042]Replace the 2L stainless steel autoclave with nitrogen for three times, then add 250g of tetrahydrofuran solution of methylmagnesium chloride (the concentration of methylmagnesium chloride is 2mol / Kg) and 750g of tetrahydrofuran, and feed pentafluorochloroethane while stirring at 20°C 200g, continue to react for 5 hours after passing through. After the reaction is finished, stop stirring, cool to 10°C, and filter to obtain 1,1,1,2,2-pentafluoropropane synthetic liquid, the purity of which is 99.5% after rectification and purification. Calculated on the basis of methylmagnesium chloride, the yield of 1,1,1,2,2-pentafluoropropane is 73.5%.

[0043] (2) Preparation of 2,3,3,3-tetrafluoropropene

[0044] The 1,1,1,2,2-pentafluoropropane obtained by the reaction in step (1) is passed through a calcium hydroxide solution with an excess mass percent concentration of 20% and a temperature of 90°C, and the gas phase produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com