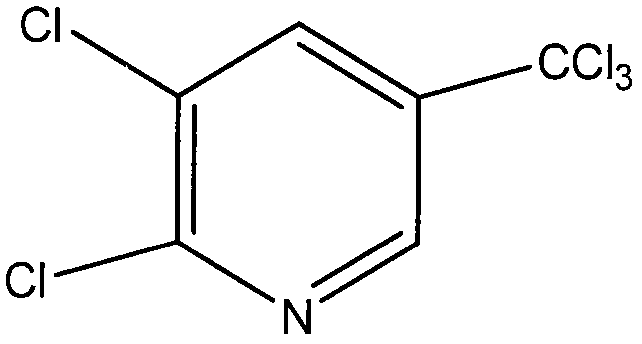

Method for preparing 2,3-dichloro-5-trichloromethylpyridine from DCTF distillation and rapid-steaming residues

A technology of trichloromethylpyridine and chloropyridine, which is applied in organic chemistry and other fields, and can solve problems such as difficult harmless treatment, non-combustibility or flammability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

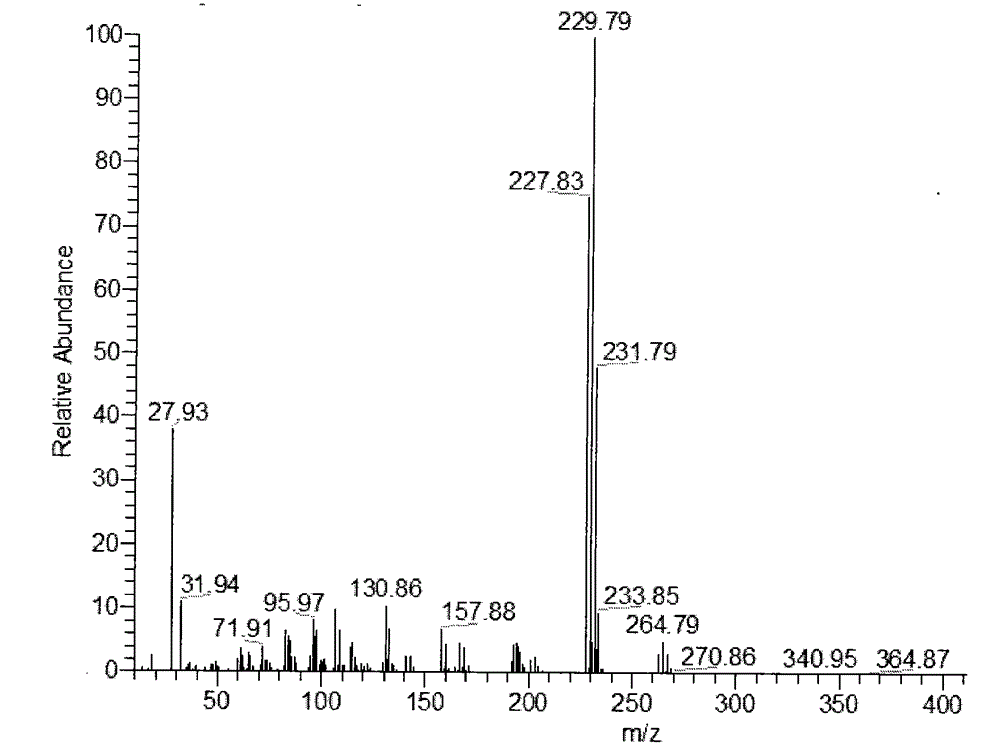

Image

Examples

Embodiment 1

[0013]1000 grams of DCTF rectification short-distillation residue and 100 grams are made of aluminum oxide, silicon dioxide, zirconia, 4A zeolite, magnesium oxide, mordenite, and HZSM-5 zeolite in a mass ratio of 0.01: 30: 10: 20: 10 : The catalyst composed of 0.01:0.1 is added into the reactor together, stirred and under the conditions of 0.01MPa vacuum degree and 400°C, the in-situ catalytic cracking and vacuum distillation of the DCTF rectification and short distillation residue are realized, so that the The polymers formed by the chloropyridine compounds, fluorochloropyridine compounds and fluoropyridine compounds in the residue under high temperature conditions are converted into 2,3-dichloro-5-trichloromethylpyridine, 2,5 , 6-trichloro-3-trifluoromethylpyridine, 2,3,4,6-tetrachloro-5-trifluoromethylpyridine, 2,3,6-trichloro-5-(dichlorofluoromethyl ) pyridine, 2,3,6-trichloro-5-(difluorochloromethyl)pyridine, 5,6-dichloro-3-hydroxymethylpyridin-2-ol, 2,3-dichloro-5- (Dic...

Embodiment 2

[0015] 1000 grams of DCTF rectification short-distillation residue and 50 grams of aluminum oxide, silicon dioxide, zirconia, 4A zeolite, magnesium oxide, mordenite, and HZSM-5 zeolite are in a mass ratio of 0.1:2:1:0.1:3 : The catalyst composed of 0.1:0.01 is added into the reactor together, stirred and under the conditions of 0.05MPa vacuum degree and 350°C, the in-situ catalytic cracking and vacuum distillation of the short-distillation residue of DCTF rectification are realized, so that the short-distillation residue present in DCTF rectification The polymers formed by the chloropyridine compounds, fluorochloropyridine compounds and fluoropyridine compounds in the residue under high temperature conditions are converted into 2,3-dichloro-5-trichloromethylpyridine, 2,5 , 6-trichloro-3-trifluoromethylpyridine, 2,3,4,6-tetrachloro-5-trifluoromethylpyridine, 2,3,6-trichloro-5-(dichlorofluoromethyl ) pyridine, 2,3,6-trichloro-5-(difluorochloromethyl)pyridine, 5,6-dichloro-3-hydr...

Embodiment 3

[0017] 1000 grams of DCTF rectification short-distillation residue and 10 grams are made of aluminum oxide, silicon dioxide, zirconia, 4A zeolite, magnesium oxide, mordenite, and HZSM-5 zeolite in a mass ratio of 1: 0.2: 1: 0.01: 15 : The catalyst composed of 10:10 is added into the reactor together, stirred and under the conditions of 0.09MPa vacuum degree and 300 ℃ to realize the in-situ catalytic cracking and vacuum distillation of the DCTF rectification short distillation residue, so that the short distillation residue present in the DCTF rectification short distillation The polymers formed by the chloropyridine compounds, fluorochloropyridine compounds and fluoropyridine compounds in the residue under high temperature conditions are converted into 2,3-dichloro-5-trichloromethylpyridine, 2,5 , 6-trichloro-3-trifluoromethylpyridine, 2,3,4,6-tetrachloro-5-trifluoromethylpyridine, 2,3,6-trichloro-5-(dichlorofluoromethyl ) pyridine, 2,3,6-trichloro-5-(difluorochloromethyl)pyri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com