Method and system for processing zinc volatilization kiln slag

A technology for zinc volatilization and kiln slag, applied in the field of zinc volatilization kiln slag treatment, can solve the problems of environmental pollution, poor economy, waste of social resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

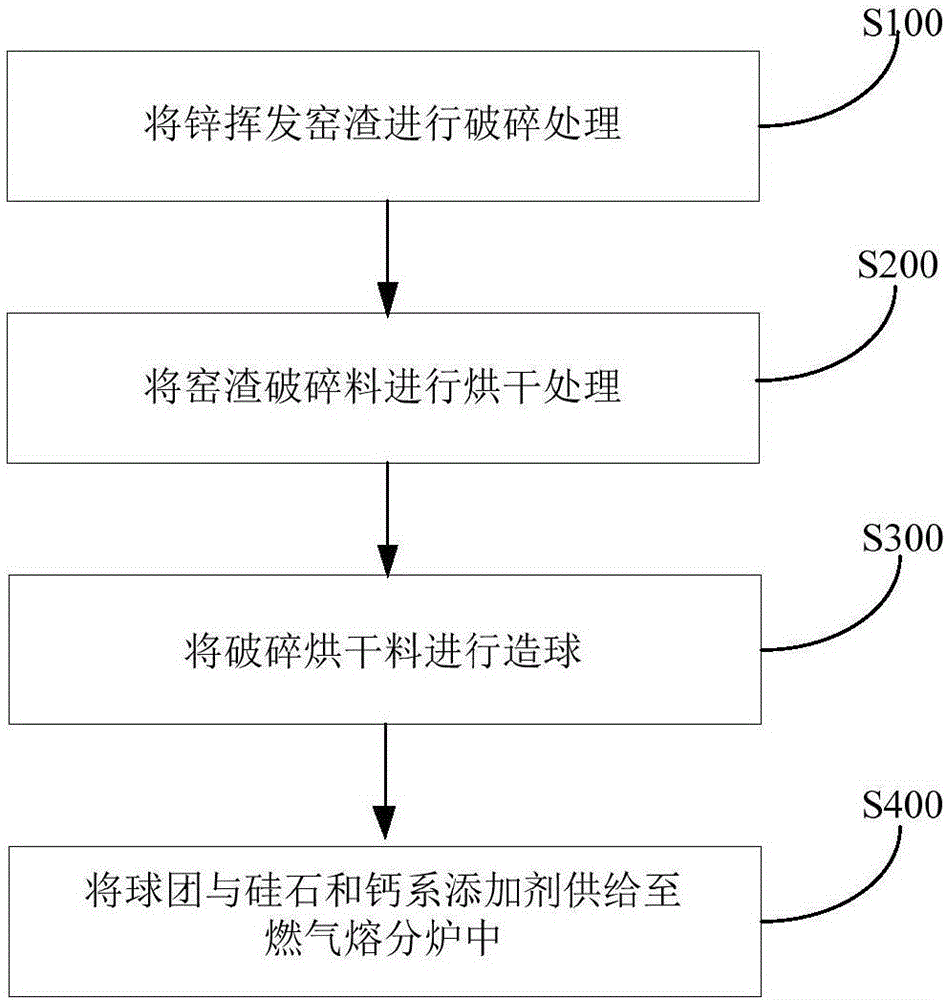

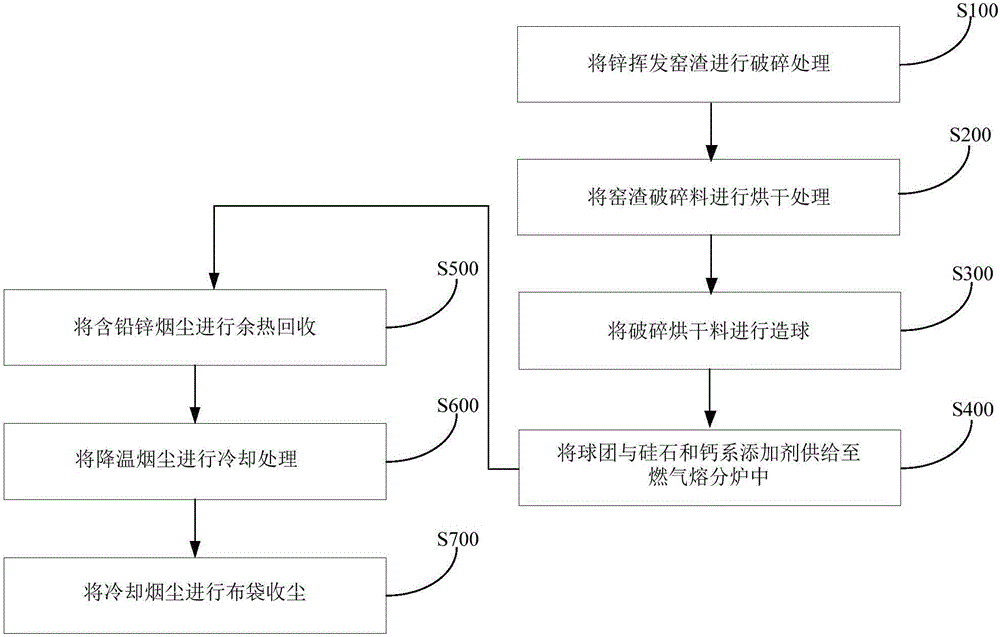

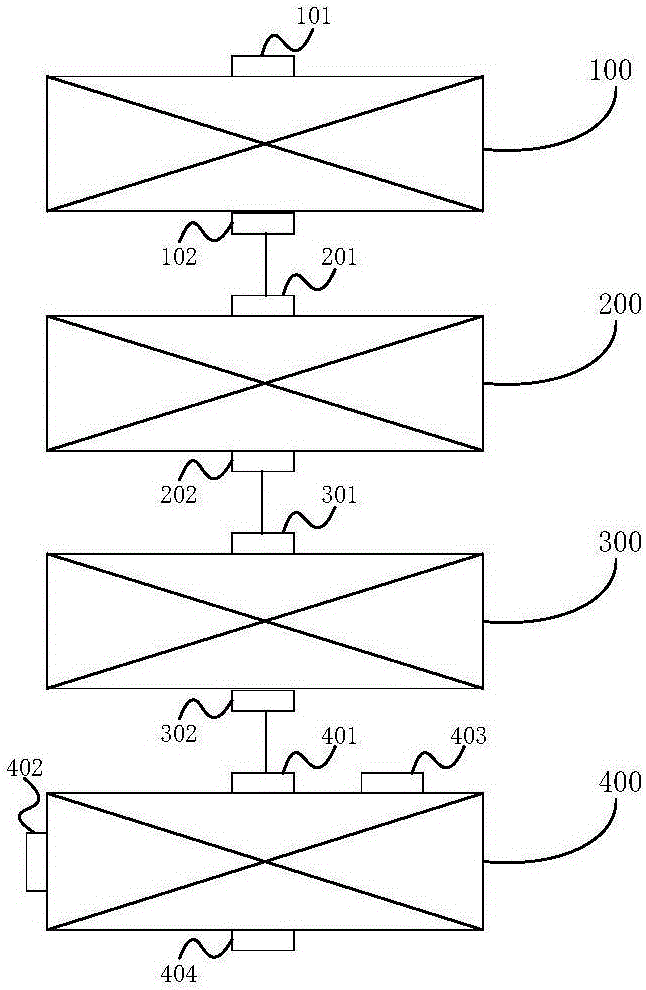

Method used

Image

Examples

Embodiment 1

[0076] Zinc volatilization kiln slag contains 24wt% iron, of which metallic iron accounts for 53wt% of total iron, lead content is 1.5wt%, zinc content is 3.8wt%, silver content is 110g / t, carbon content is 35wt%, indium content is 180g / t; First, crush the zinc volatilization kiln slag until the particle size is not higher than 3mm, then dry it to obtain a dry material with a moisture content of not higher than 0.5wt% kiln slag, and then pelletize it through a disc pelletizer to obtain pellets , raise the temperature of the gas melting furnace to 1560 degrees Celsius, keep it warm for 30 minutes, and then put the dried pellets into the molten pool, so that the liquid level of the molten pool reaches one-third of the height of the gas melting furnace, and the molten pool is completed Afterwards, continuous feeding is carried out. During the feeding process, it is necessary to ensure that all the materials of the previous batch are completely melted, and then the next batch of m...

Embodiment 2

[0078] Zinc volatilization kiln slag contains 32wt% iron, of which metallic iron accounts for 55wt% of total iron, lead content is 1.8wt%, zinc content is 4.3wt%, silver content is 120g / t, carbon content is 38wt%, indium content is 220g / t; crush the zinc volatilization kiln slag until the particle size is not higher than 3mm, and then dry it to obtain the dried crushed material with a moisture content of not higher than 0.5wt%, and then pelletize it through a disc pelletizer to obtain pellets. The temperature of the gas melting furnace is raised to 1580 degrees Celsius, and the temperature is kept for 30 minutes, and then the dried pellets are put into the molten pool, so that the liquid level of the molten pool reaches one-third of the height of the gas melting furnace. After the molten pool is built, For continuous feeding, the feeding process must ensure that the previous batch of materials are completely melted and then the next batch of materials is added so that the liqu...

Embodiment 3

[0080] Zinc volatilization kiln slag contains 38wt% iron, of which metallic iron accounts for 49wt% of total iron, lead content is 3.0wt%, zinc content is 5.0wt%, silver content is 138g / t, carbon content is 33wt%, indium content is 256g / t; Firstly, the zinc volatilization kiln slag is crushed until the particle size is not higher than 3mm, and then dried to obtain a crushed and dried material with a moisture content of not higher than 0.5wt%, and then pelletized by a disc pelletizer to obtain pellets , raise the temperature of the gas melting furnace to 1600 degrees Celsius, keep it warm for 30 minutes, and then put the dried kiln slag pellets into the molten pool, so that the liquid level of the molten pool reaches one-third of the height of the gas melting furnace, and the molten pool After the production is complete, continuous feeding is carried out. During the feeding process, it is necessary to ensure that all the materials of the previous batch are completely melted, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com