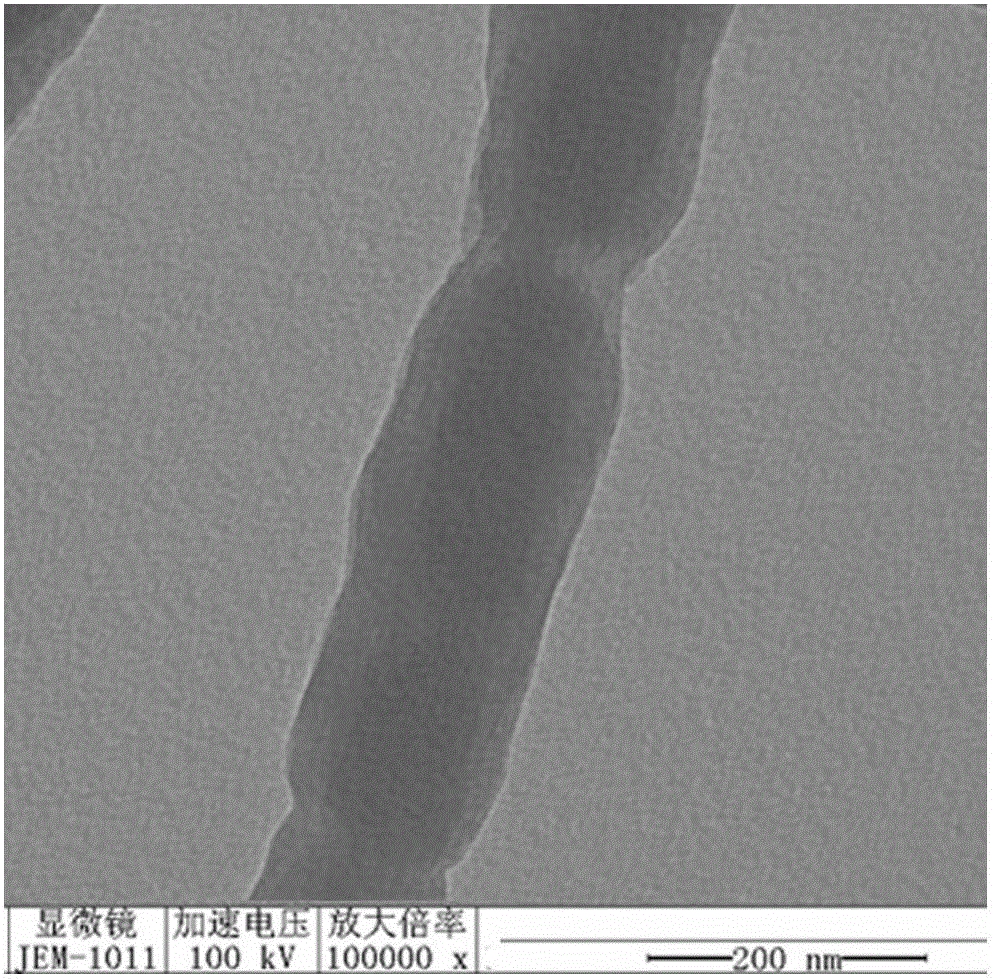

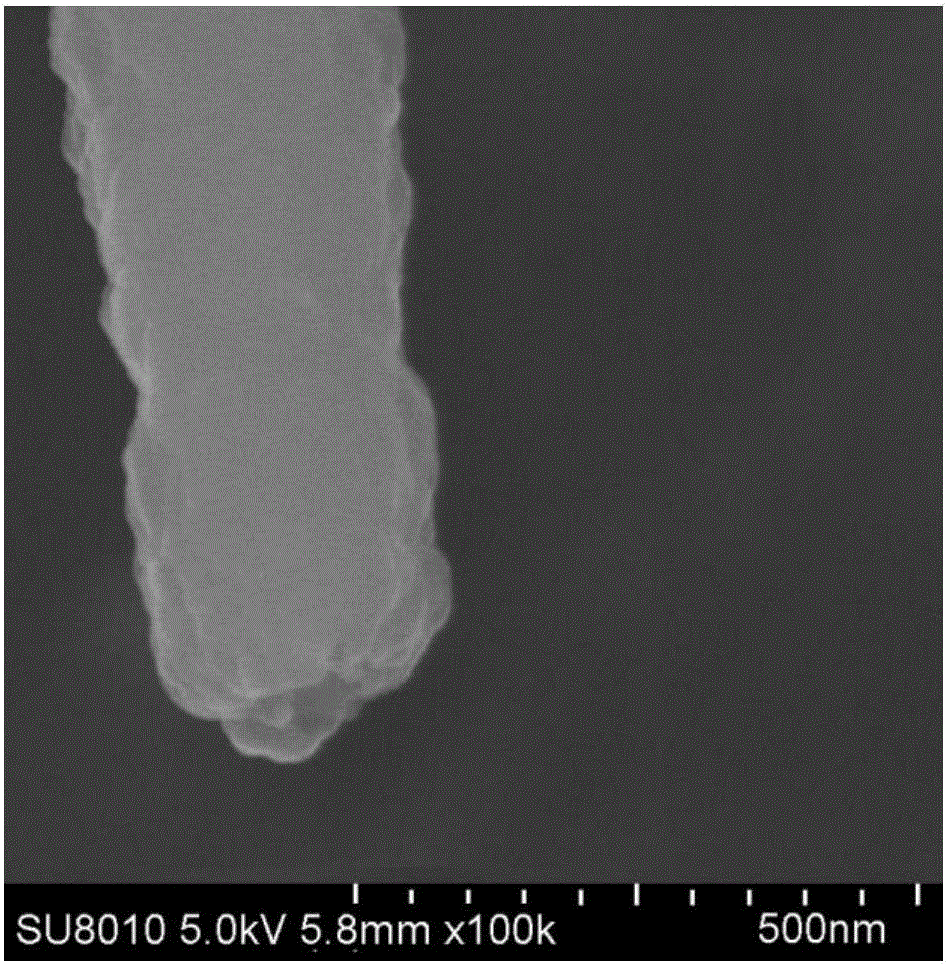

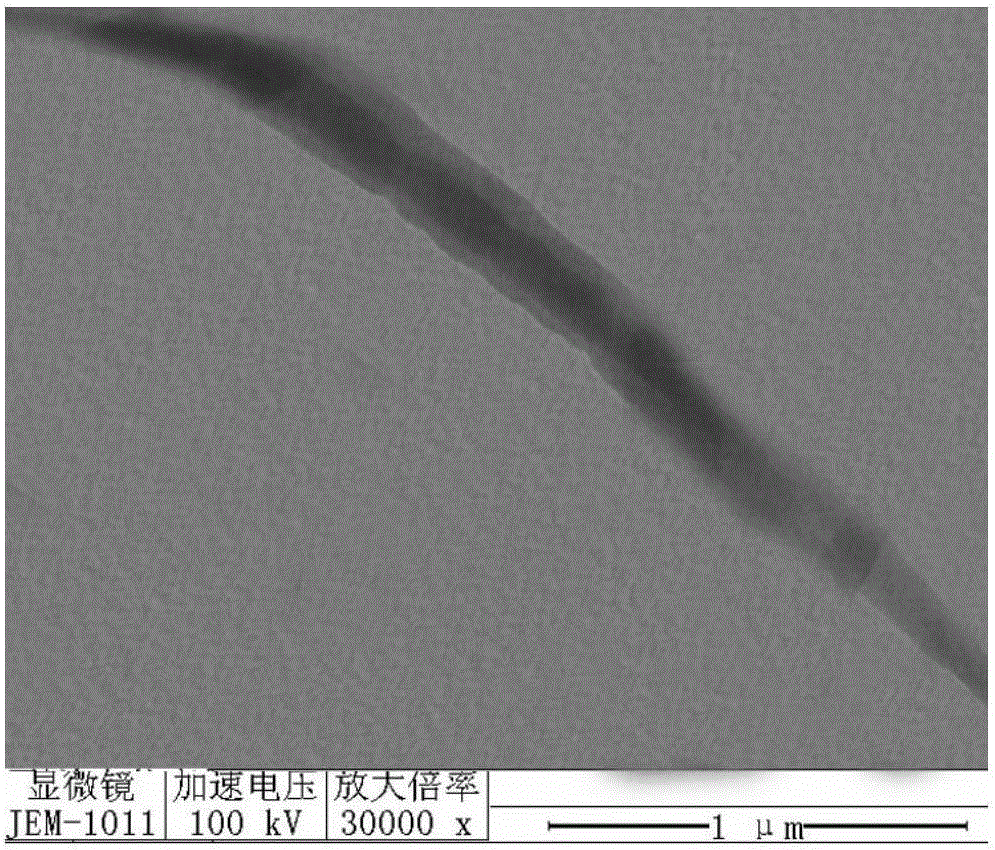

Preparation method of high-yield core-shell drug-loading PAN nanofiber

A core-shell structure, nanofiber technology, applied in fiber processing, pharmaceutical formulations, fiber chemical characteristics, etc., can solve the problems of safe use, agglomeration, influence on emulsion stability, and fiber yield reduction, etc. The effect of good sustained release performance and high fiber yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Take oxytetracycline hydrochloride 0.15g and dissolve in 5mL deionized water with an electronic balance, stir and dissolve to obtain a uniform drug aqueous solution;

[0041] (2) Weigh 8 g of polyacrylonitrile (PAN) with a viscosity-average molecular weight of 70,000 KDa and place it in a conical flask, stir and dissolve with 100 mL of DMF to obtain a uniform polymer solution;

[0042] (3) Add the uniform drug aqueous solution dropwise into the homogeneous polyacrylonitrile polymer solution under stirring state, and stop stirring after stirring at room temperature for 10 hours to form a spinning solution, which is a uniform, stable and transparent solution;

[0043] (4) Electrospinning the spinning solution using a NSLAB 500 nanospider electrospinning machine to prepare gel fibers;

[0044]The steps and process conditions of electrospinning are: firstly, the spinning solution is added to the liquid storage tank, the linear electrode is used as the spinning electrode...

Embodiment 2

[0048] (1) Take tetracycline hydrochloride 0.2g and dissolve in 5mL deionized water with an electronic balance, stir and dissolve to obtain a uniform drug aqueous solution;

[0049] (2) Weigh 9 g of polyacrylonitrile (PAN) with a viscosity-average molecular weight of 80,000 KDa and place it in a conical flask, stir and dissolve with 100 mL of DMF to obtain a uniform polymer solution;

[0050] (3) Add the uniform drug aqueous solution dropwise into the polyacrylonitrile polymer homogeneous solution under stirring state, and stop stirring after stirring at room temperature for 12 hours to form a spinning solution, which is a uniform, stable and transparent solution;

[0051] (4) Electrospinning the spinning solution using a NSLAB 500 nanospider electrospinning machine to prepare gel fibers; the steps and process conditions of the electrospinning are: first, the spinning solution is added to the liquid storage tank, and the linear The electrode was used as the spinning electrode,...

Embodiment 3

[0055] (1) Take 0.3 g of doxycycline hydrochloride with an electronic balance and dissolve it in 5 mL of deionized water, stir and dissolve to obtain a uniform drug aqueous solution;

[0056] (2) Weigh 8 g of polyacrylonitrile (PAN) with a viscosity-average molecular weight of 90,000 Kda and place it in a conical flask, stir and dissolve with 95 mL of DMF to obtain a uniform polymer solution;

[0057] (3) Add the uniform drug aqueous solution dropwise into the polyacrylonitrile polymer homogeneous solution under stirring state, and stop stirring after stirring at room temperature for 16 hours to form a spinning solution, which is a uniform, stable and transparent solution;

[0058] (4) Electrospinning the spinning solution using a NSLAB 500 nanospider electrospinning machine to prepare gel fibers;

[0059] The steps and process conditions of electrospinning are: firstly, the spinning solution is added to the liquid storage tank, the linear electrode is used as the spinning ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity average molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| viscosity average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com