Measuring method for acid value of unsaturated polyester resin emulsion

A technology of polyester resin and determination method, which is applied in the direction of chemical analysis by titration method, which can solve the problems of insoluble substances, human injury, and insufficient scope of application, so as to improve stability and accuracy, avoid human errors, and achieve good results. Solubility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Reagents

[0035] Propylene glycol methyl ether (analytical pure), acetone (analytical pure), potassium hydroxide (analytical pure), ethanol (95%), potassium hydrogen phthalate (standard), phenolphthalein indicator: 10g / L, carbon dioxide-free water ( For water quality above grade 3 in the laboratory, heat to boiling for 3 minutes, remove carbon dioxide in the water, and cool to room temperature).

[0036] 2. Instrument

[0037] Potentiometric titrator (Mettler T-50), electrode (Mettler DGI 113-SC), electronic balance (Sartorius BS224S), electric oven (SC101-3), 10ml alkaline burette, 100ml, poly Vinyl container (1000ml), brown ground bottle (1000ml)

[0038] 3. Solution preparation

[0039] 3.1 0.1mol / L potassium hydroxide-ethanol standard titration solution: configure and calibrate according to "Preparation of GB 601-2002 Chemical Reagent Standard Titration Solution".

[0040] 3.2 Preparation of mixed solvent: Pour 600 ml of acetone and 300 ml of propylene glyco...

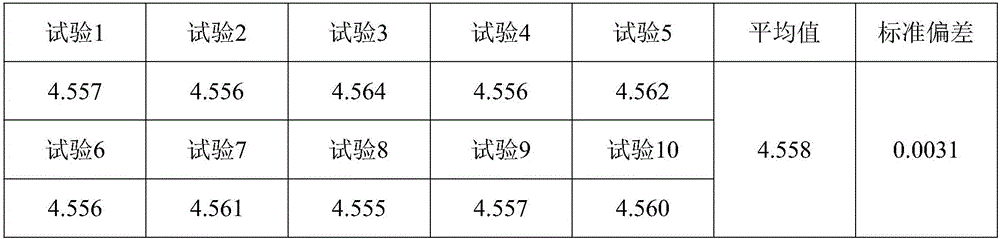

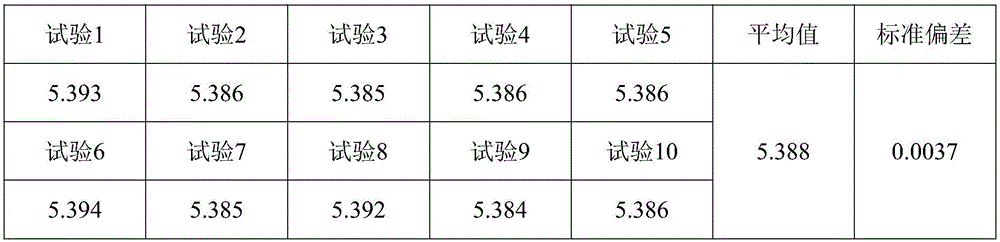

Embodiment 2

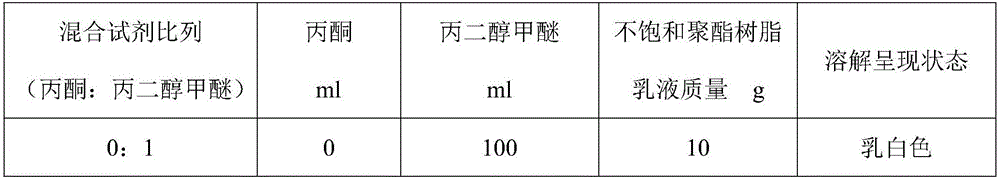

[0067]Test the dissolving effect of mixed solvents in different proportions on the unsaturated polyester resin emulsion sample, and select the most suitable ratio therefrom. The results are shown in Table 2:

[0068] Table 2

[0069]

[0070]

[0071] From the perspective of dissolution effect, use a single solvent (only with acetone or only with propylene glycol methyl ether, the sample cannot be completely dissolved); 100 milliliters of mixed reagents with a ratio of 1:1 cannot completely dissolve 10 grams of samples; The amount of acetone and propylene glycol methyl ether used, when the ratio of acetone and propylene glycol methyl ether is 3:2, the sample begins to dissolve; when the ratio of acetone and propylene glycol methyl ether in the mixed solvent reaches 2:1, the solution reaches a colorless and transparent state. When the ratio of acetone to propylene glycol methyl ether in the miscible solvent reaches 4:1, the wall-mounted droplets are milky white, and some ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com