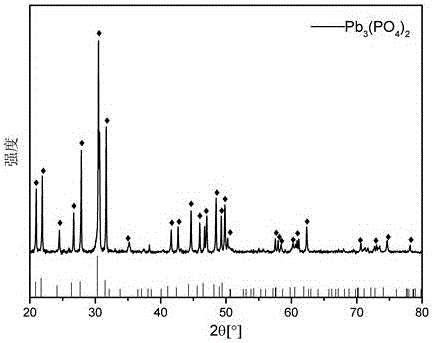

Method for preparing Pb3(PO4)2 nanowire film

A nanowire and thin film technology, applied in the field of preparing Pb32 nanowire thin film, can solve the problems of unsatisfactory requirements, low purity of lead phosphate, irregular shape, etc., and achieve the effect of low cost, easy large-scale production, and regular shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

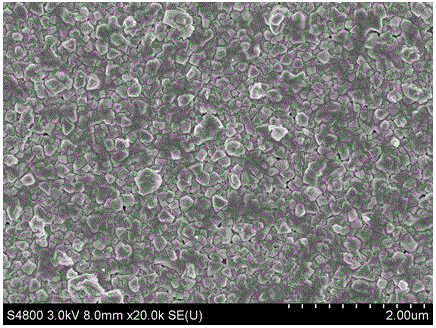

Embodiment 1

[0018] (1) The pre-cut conductive glass electrode was ultrasonically cleaned for 3 minutes with analytical acetone, analytical pure ethanol and secondary water respectively, and air-dried to prepare the matrix electrode.

[0019] (2) Measure 1 mL of Pb(NO 3 ) 2 solution, 1 mL of 0.2 mol / L EDTA solution, 3.5 mL of 0.3 mol / L Na 2 S 2 o 3 solution and 4 mL of Na at a concentration of 1.25 mol / L 2 SO 4 The solutions were placed in a 20 mL beaker and mixed evenly to obtain the bottom solution of electrodeposited PbS film.

[0020] (3) set up a three-electrode system in the electrodeposited PbS thin film bottom liquid that step (2) makes, wherein, the substrate electrode that step (1) makes is as working electrode, and Ag / AgCl is reference electrode, and Pt is auxiliary electrode , using cyclic voltammetry for electrodeposition, the scanning range is -1~0V, the scanning speed is 0.05V / s, and the number of scanning segments is 50. After the deposition is completed, the working ...

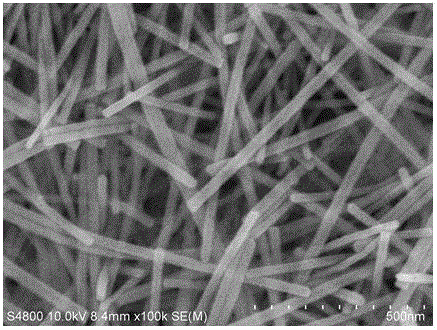

Embodiment 2

[0026] (1) The pre-cut conductive glass electrode was ultrasonically cleaned for 3 minutes with analytical acetone, analytical pure ethanol and secondary water respectively, and air-dried to prepare the matrix electrode.

[0027] (2) Measure 1 mL of Pb(NO 3 ) 2 solution, 1 mL of 0.2 mol / L EDTA solution, 3.5 mL of 0.3 mol / L Na 2 S 2 o 3 solution and 4 mL of Na at a concentration of 1.25 mol / L 2 SO 4 The solutions were placed in a 20 mL beaker and mixed evenly to obtain the bottom solution of electrodeposited PbS film.

[0028] (3) set up a three-electrode system in the electrodeposited PbS thin film bottom liquid that step (2) makes, wherein, the matrix electrode that step (1) makes is as working electrode, and Ag / AgCl is reference electrode, and Pt is auxiliary electrode , using cyclic voltammetry for electrodeposition, the scanning range is -1~0V, the scanning speed is 0.05V / s, and the number of scanning segments is 60. After the deposition is completed, the working ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com