A kind of poly(styrene-methacrylic acid)-polyaniline-nanometer silver composite microsphere and preparation method thereof

A technology of methacrylic acid and composite microspheres, which is applied in the field of composite materials, can solve problems such as limited catalytic efficiency, complex preparation methods, and high environmental risks, and achieve excellent catalytic performance, simple preparation methods, and improved catalytic efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

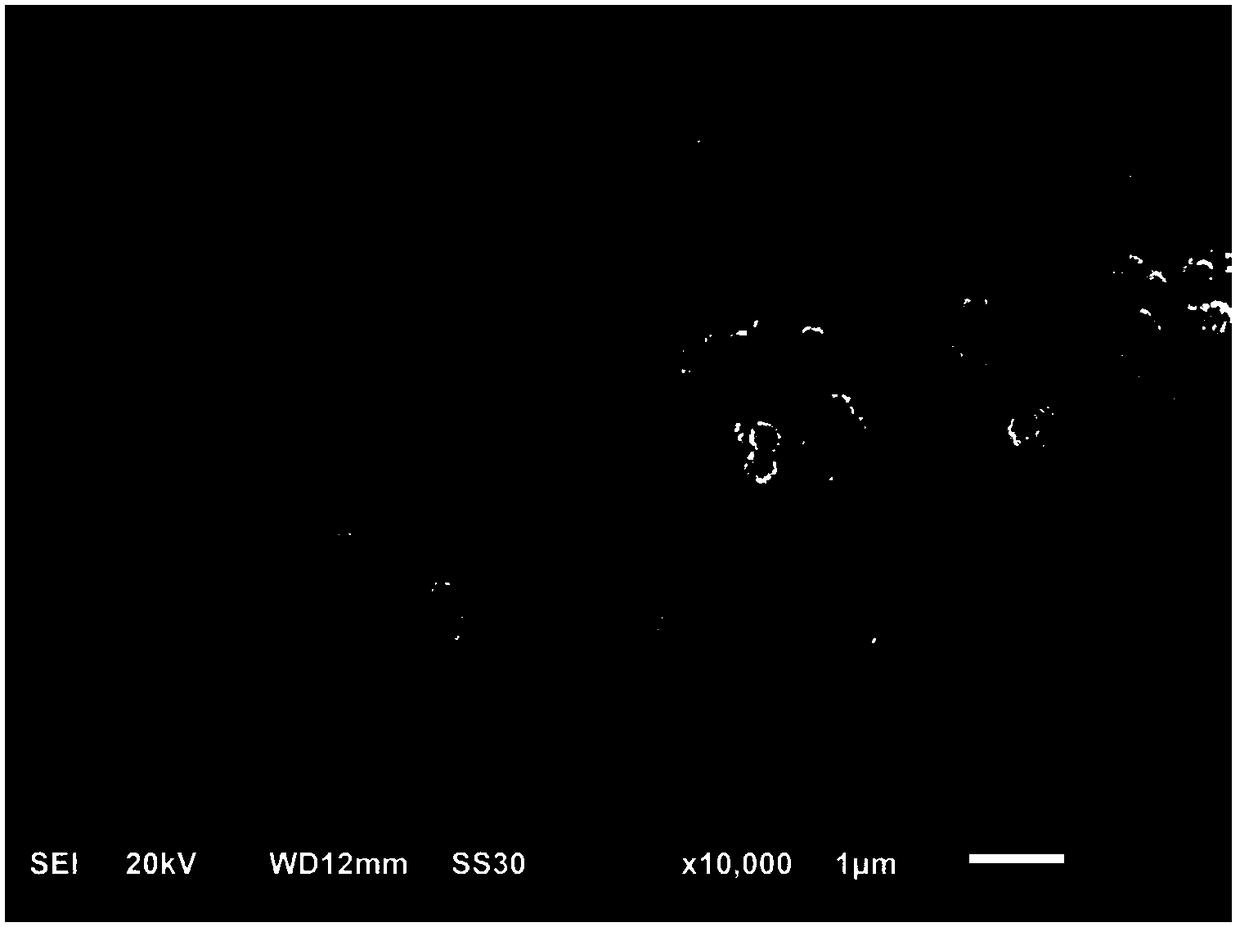

[0027] S1. Preparation of poly(styrene-methacrylic acid) microspheres: Add 15mL of styrene, 1mL of methacrylic acid and 125mL of deionized water into a 250mL four-necked flask, bubbling with nitrogen gas and deoxygenating for 30 minutes, and then heating to 70 ℃, add 0.625g potassium persulfate, react for 24h under the protection of nitrogen at constant pressure, centrifuge, wash, and dry to obtain poly(styrene-methacrylic acid) microspheres;

[0028] S2. Preparation of poly(styrene-methacrylic acid)-polyaniline composite microspheres: 20mL of deionized water, 0.014g (0.15mmol) of aniline and 3.41g of poly(styrene-methacrylic acid) microspheres prepared by S1 Add to a 100mL three-necked flask, stir for 1h at room temperature, add 0.9mmol ferric nitrate, react at room temperature for 12h, centrifuge, wash, and dry to obtain poly(styrene-methacrylic acid)-polyaniline composite microspheres;

[0029] S3. Preparation of poly(styrene-methacrylic acid)-polyaniline-nanosilver composite mi...

Embodiment 2

[0031] S1. Preparation of poly(styrene-methacrylic acid) microspheres: add 20mL of styrene, 3mL of methacrylic acid and 125mL of deionized water into a 250mL four-necked flask, bubbling with nitrogen gas and deoxygenating for 30 minutes, and then heating to 75 ℃, add 0.625g potassium persulfate, react for 24h under the protection of nitrogen at constant pressure, centrifuge, wash, and dry to obtain poly(styrene-methacrylic acid) microspheres;

[0032] S2. Preparation of poly(styrene-methacrylic acid)-polyaniline composite microspheres: 25mL deionized water, 0.023g (0.25mmol) aniline and 3.41g poly(styrene-methacrylic acid) microspheres prepared by S1 Add to a 100mL three-necked flask, stir at room temperature for 1h, add 1.5mmol ferric nitrate, react at room temperature for 20h, centrifuge, wash, and dry to obtain poly(styrene-methacrylic acid)-polyaniline composite microspheres;

[0033] S3. Preparation of poly(styrene-methacrylic acid)-polyaniline-nanosilver composite microsphere...

Embodiment 3

[0035] S1. Preparation of poly(styrene-methacrylic acid) microspheres: Put 18mL styrene, 2mL methacrylic acid and 125mL deionized water into a 250mL four-necked flask, bubbling with nitrogen gas and deoxygenating for 30 minutes, and then heating to 65 ℃, add 0.625g potassium persulfate, react for 20h under the protection of nitrogen at constant pressure, centrifuge, wash and dry to obtain poly(styrene-methacrylic acid) microspheres;

[0036] S2. Preparation of poly(styrene-methacrylic acid)-polyaniline composite microspheres: 20mL deionized water, 0.19g (0.020mmol) aniline and 3.41g poly(styrene-methacrylic acid) microspheres prepared by S1 Add to a 100mL three-necked flask, stir at room temperature for 1h, add 1.2mmol ferric chloride, react at room temperature for 18h, centrifuge, wash, and dry to obtain poly(styrene-methacrylic acid)-polyaniline composite microspheres;

[0037] S3. Preparation of poly(styrene-methacrylic acid)-polyaniline-nanosilver composite microspheres: 25mL o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com