Polyacrylamide (PAM) solid compound polymer electrolyte and preparation method thereof

A polyacrylamide and composite polymer technology, applied in the field of composite polymer electrolyte component design and preparation, can solve problems such as difficulty of uniform mixing by common methods, and achieve high room temperature conductivity, lithium ion migration number, and good dimensional stability. The effect of avoiding solvent volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The technical solution of the present invention is not limited to the following specific implementation manners.

[0020] Weigh 0.6g LiClO 4 and 0.25g nano Y 2 o 3 , dried in vacuum at 100°C for 24h before use.

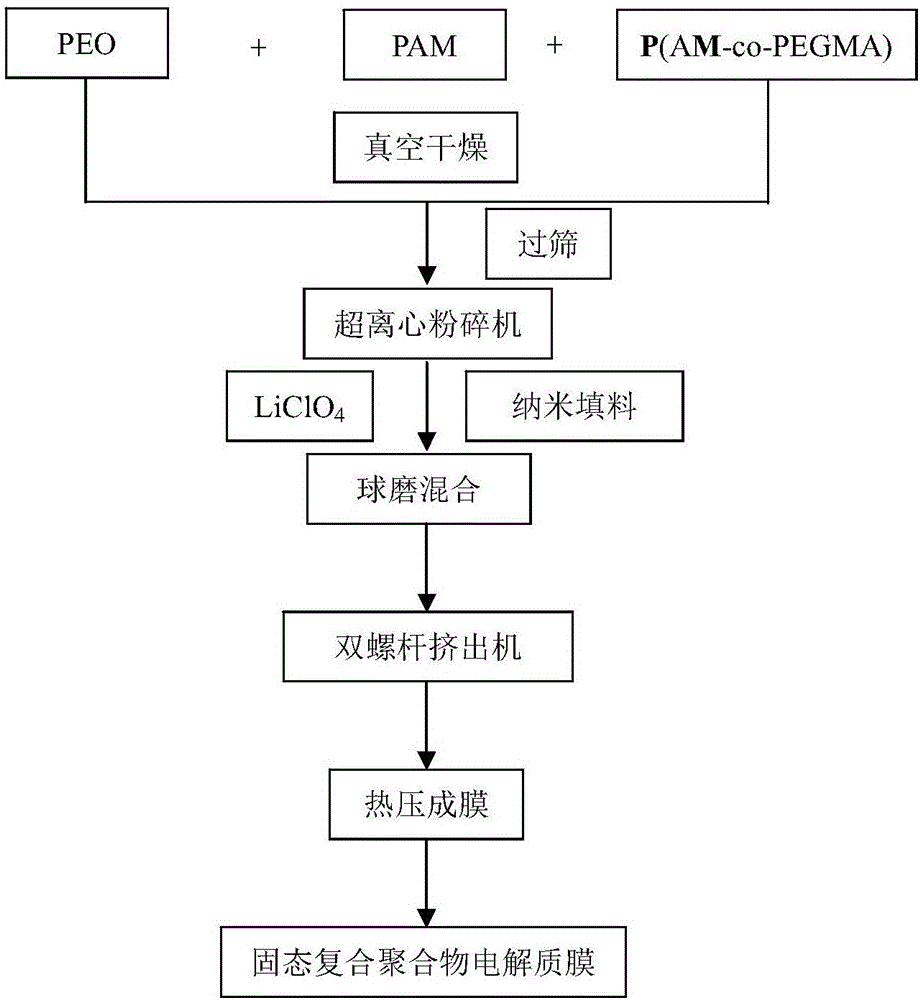

[0021] Weigh 4.8g of PEO with a molecular weight of 200,000 in proportion; a molecular weight of 2.4 million is PAM 1.3g; a molecular weight of 2.0×10 4 1.2g of P(AM-co-PEGMA), wherein the mass fraction of PEGMA in P(AM-co-PEGMA) accounts for 70%, and AM accounts for 30%. The above-mentioned polymer matrix was sent to an ultracentrifugal pulverizer, and an ultracentrifuge with a diameter of 99 mm and a 12-tooth rotary knife was selected for pulverization, pulverized for 3 minutes, and passed through a trapezoidal sieve with a pore size of 125 μm, and repeated 3 times. Under the protection of nitrogen atmosphere, the dried LiClO 4 , nano Y 2 o 3 The pulverized polymer matrix is sent to a nitrogen-protected planetary ball mill, and after ball milling for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com