Method for treating chromium-containing wastewater by using straw cellulose-cerium oxide composite through photocatalytic reduction

A technology of straw cellulose and cerium oxide, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as hazards and carcinogenicity, and achieve high photocatalytic removal rate , reduced bandgap width, and high industrial application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

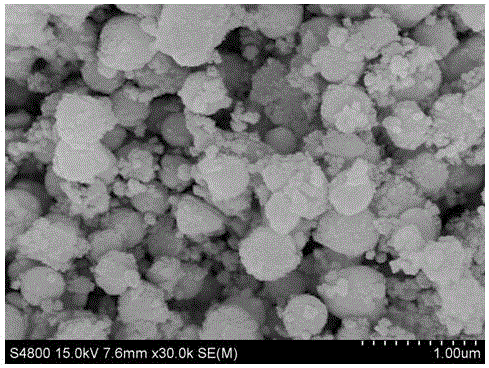

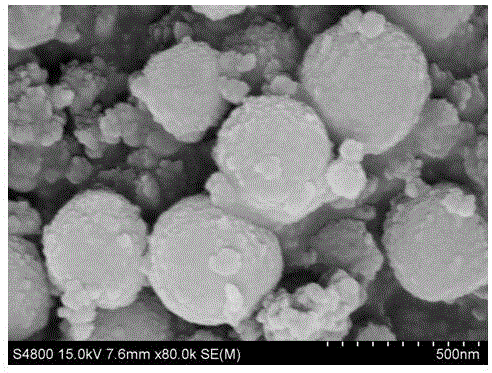

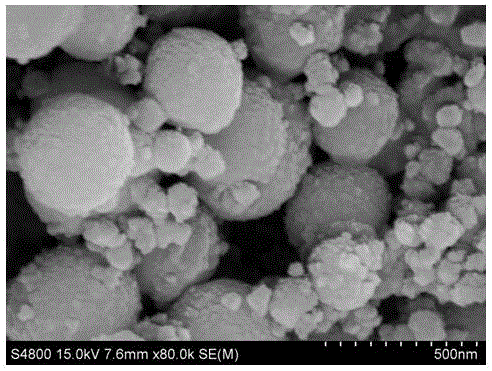

Image

Examples

Embodiment 1

[0038] A method for treating chromium-containing wastewater by catalytic reduction of straw cellulose-cerium oxide composite of the present invention comprises the following steps in sequence:

[0039] (1) Weighing 10-20 grams of straw pulp, adding it to an aqueous solution containing 0.05-0.2 grams of TEMPO and 0.5-1.5 grams of sodium bromide;

[0040] (2) configure a sodium hypochlorite solution with a mass fraction of 3 to 6%, and adjust its pH in a suitable range with a hydrochloric acid solution of 0.05 to 0.3 mol / liter;

[0041] (3) Slowly add (2) to the mixed solution obtained in step (1), and stir vigorously;

[0042] (4) adjust step (3) pH in a suitable range with 0.2~1.0 mol / liter of sodium hydroxide solution and keep the reaction for several hours;

[0043] (5) After the reaction product of step (4) is suction filtered to remove water, it is washed with deionized water repeatedly until the pH value of the solution is close to 7.0, and the washed reaction product is...

Embodiment 2

[0049] A method for treating chromium-containing wastewater by catalytic reduction of straw cellulose-cerium oxide composite of the present invention comprises the following steps in sequence:

[0050] (1) Weighing 10-20 grams of straw pulp, adding it to an aqueous solution containing 0.05-0.2 grams of TEMPO and 0.5-1.5 grams of sodium bromide;

[0051] (2) configure a sodium hypochlorite solution with a mass fraction of 3 to 6%, and adjust its pH in a suitable range with a hydrochloric acid solution of 0.05 to 0.3 mol / liter;

[0052] (3) Slowly add (2) to the mixed solution obtained in step (1), and stir vigorously;

[0053] (4) adjust step (3) pH in a suitable range with 0.2~1.0 mol / liter of sodium hydroxide solution and keep the reaction for several hours;

[0054] (5) After the reaction product of step (4) is suction filtered to remove water, it is washed with deionized water repeatedly until the pH value of the solution is close to 7.0, and the washed reaction product is...

Embodiment 3

[0060] A method for treating chromium-containing wastewater by catalytic reduction of straw cellulose-cerium oxide composite of the present invention comprises the following steps in sequence:

[0061] (1) Weighing 10-20 grams of straw pulp, adding it to an aqueous solution containing 0.05-0.2 grams of TEMPO and 0.5-1.5 grams of sodium bromide;

[0062] (2) configure a sodium hypochlorite solution with a mass fraction of 3 to 6%, and adjust its pH in a suitable range with a hydrochloric acid solution of 0.05 to 0.3 mol / liter;

[0063] (3) Slowly add (2) to the mixed solution obtained in step (1), and stir vigorously;

[0064] (4) adjust step (3) pH in a suitable range with 0.2~1.0 mol / liter of sodium hydroxide solution and keep the reaction for several hours;

[0065] (5) After the reaction product of step (4) is suction filtered to remove water, it is washed with deionized water repeatedly until the pH value of the solution is close to 7.0, and the washed reaction product is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com