Preparation method of flame-retardant and high-heat-resisting polyethylene terephthalate

A technology of ethylene glycol phthalate and high heat resistance, applied in the field of polymer material preparation, can solve the problems that PET cannot meet the application requirements, CPET has poor toughness, poor flame retardancy, etc., and achieves excellent mechanical properties and processing Excellent performance and improved heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of flame-retardant, high heat-resistant polyethylene terephthalate,

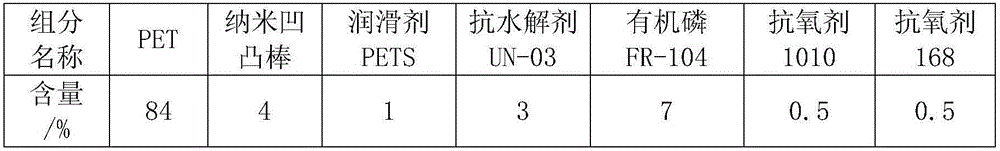

[0031] The proportioning of raw material components by mass percentage is:

[0032]

[0033] The steps are:

[0034] a. Raw material pretreatment: Dry PET in a vacuum oven at 140°C for 3 hours, dry nano-attapulgite, organic phosphorus flame retardant FR-104, antioxidant 1010 and antioxidant 168 at 110°C for 2 hours ;

[0035] b. Ingredients: weigh the dried material according to the proportion, pre-mix with the anti-hydrolysis agent UN-03 and lubricant PETS weighed according to the proportion in advance, and then continue to mix in the high-speed mixer for 10 minutes, and then discharge;

[0036] c. Processing: Add the mixture into the feeding hopper of the twin-screw extruder; under the conditions of feeding speed of 100r / min, screw speed of 400r / min, and processing temperature of 240°C, the mixture is melted, After extrusion, cooling and pelletizing, the pellets are dried ...

Embodiment 2

[0038] A preparation method of flame-retardant, high heat-resistant polyethylene terephthalate,

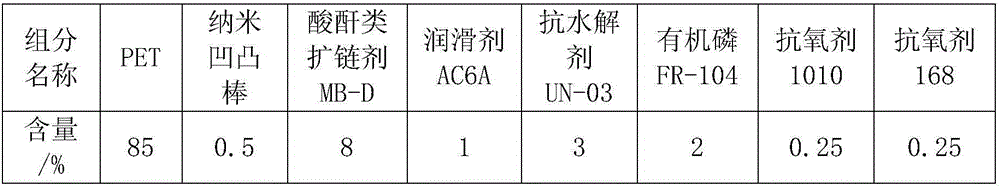

[0039] The proportioning of raw material components by mass percentage is:

[0040]

[0041] The steps are:

[0042] a. Raw material pretreatment: Put PET in a vacuum drying oven at 140°C for 3 hours and dry the nano-attapulgite, anhydride chain extender MB-D, organic phosphorus flame retardant FR-104, antioxidant 1010 and antioxidant Agent 168 was dried at 110°C for 2 hours;

[0043] b. Ingredients: weigh the dried material according to the proportion, pre-mix with the anti-hydrolysis agent UN-03 and lubricant AC6A weighed in advance, then continue to mix in the high-speed mixer for 10 minutes, and discharge;

[0044] c. Processing: Add the mixture into the feeding hopper of the twin-screw extruder; under the conditions of feeding speed of 40r / min, screw speed of 400r / min, and processing temperature of 260°C, the mixture is melted, Extruded, cooled and pelletized, the pelle...

Embodiment 3

[0046] A preparation method of flame-retardant, high heat-resistant polyethylene terephthalate,

[0047] The proportioning of raw material components by mass percentage is:

[0048]

[0049] The steps are:

[0050] a. Raw material pretreatment: Put PET and polycarbonate (PC) in a vacuum oven at 140°C for 3 hours and dry them for attapulgite, organic phosphorus flame retardant FR-104, antioxidant 1010 and antioxidant 168 Dry at 110°C for 2 hours;

[0051] b. Ingredients: weigh the dried material according to the proportion, pre-mix with the anti-hydrolysis agent UN-03 and lubricant AC6A weighed in advance, then continue to mix in the high-speed mixer for 10 minutes, and discharge;

[0052] c. Processing: Add the mixture into the feeding hopper of the twin-screw extruder; under the conditions of feeding speed of 40r / min, screw speed of 400r / min, and processing temperature of 260°C, the mixture is melted, Extruded, cooled and pelletized, the pellets were dried at 120°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com