Chemical mineral dressing pretreatment method for waste printed circuit board multi-metal powder

A waste circuit board and chemical beneficiation technology, applied in chemical instruments and methods, wet separation, process efficiency improvement, etc., can solve the problem of difficult elimination of smelting flue gas odor, difficulty in normal operation of electrolytic refining, and unqualified cathode copper quality and other problems, to achieve the effect of eliminating secondary pollution, eliminating dispersion loss, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

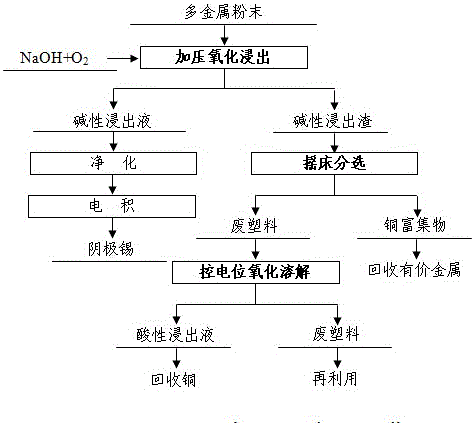

Method used

Image

Examples

Embodiment 1

[0022] The main components of the polymetallic powder produced during the crushing and sorting process of waste circuit boards in a domestic company are (%): Cu65.0, Sn8.2, Pb9.4, Au50g / t and Ag2500g / t . Both sodium hydroxide and sodium nitrate are industrial grade reagents, and their mass percentage content is not less than 98.0%.

[0023]Prepare a sodium hydroxide solution with a molar concentration of 2.5mol / L, add polymetallic powder according to the liquid-solid ratio (ratio of liquid volume to solid weight) 4:1, and add 0.4% sodium nitrate by weight of polymetallic powder as a catalyst at the same time. The mixed slurry is added to the stainless steel high-pressure reaction kettle, and the reaction temperature is controlled at 175°C and the oxygen partial pressure is 1.0MPa to react for 3.0h. After the reaction is completed, the temperature is lowered to 75°C and the liquid and solid are separated. The leaching rate of tin is more than 98.0%. ; Control the strength of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com