Nano-TiO2/activated carbon fibrofelt three-dimensional porous material high in adsorption and photocatalytic performance, and preparation method thereof

A technology of activated carbon fiber felt and nano-titanium dioxide is applied in the field of woven materials, which can solve the problems of reducing the adsorption performance of activated carbon fiber felt, secondary pollution of the environment, long preparation period, etc., and achieves excellent filtering effect, economical environment, and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

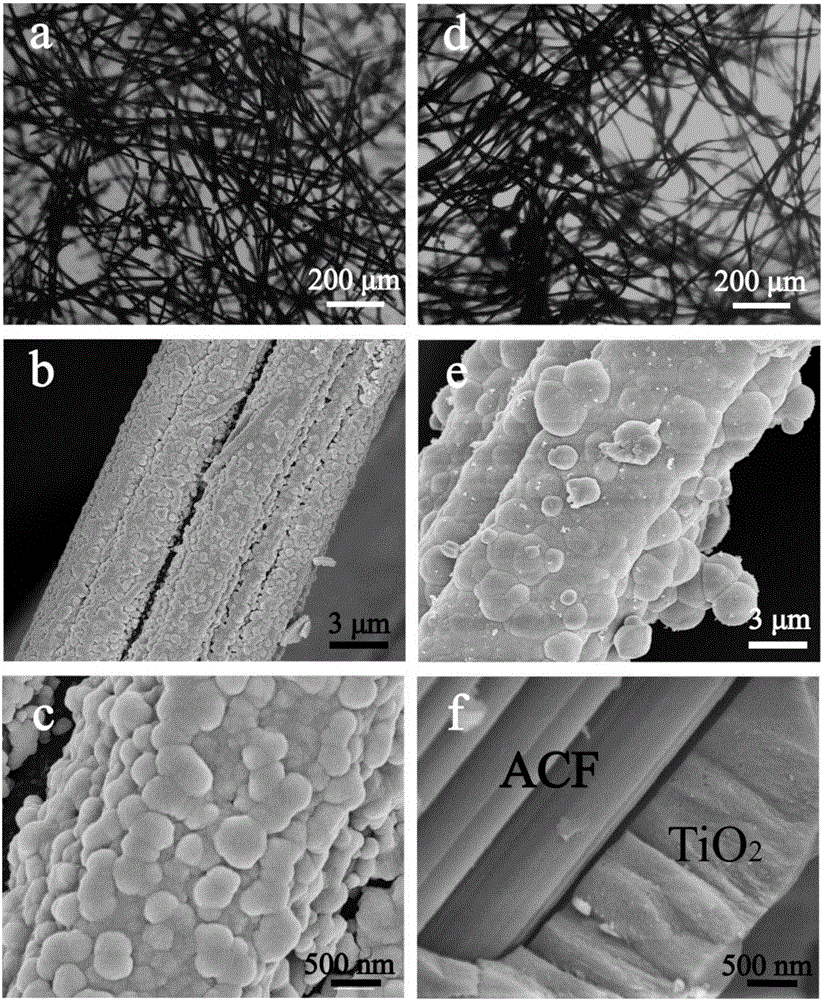

Method used

Image

Examples

Embodiment 1

[0041] (1) Accurately weigh 1.10g of zinc acetate dihydrate (5mmol) into 50mL (0.65mol) of isopropanol (AR), stir at 85°C for 15min, then add 0.7mL (5mmol) of triethylamine (AR ), stirred at 85°C for 5min, and aged at room temperature for 3h to obtain a zinc oxide crystal layer solution.

[0042] (2) Activated carbon fiber felt (thickness: 1mm, specific surface area 1100m 2 / g) cut into 2cm*2cm*1mm blocks, placed in the pretreatment solution containing 5mmol / L Triton-X100, 5mmol / L citric acid monohydrate and 300mmol / L sodium hydroxide, stirred at 100°C for 1.5 h; after being washed with deionized water and ethanol respectively, dried at 60° C. for 1 hr.

[0043] (3) step (2) is pretreated and dried active carbon fiber mat is immersed in the zinc oxide crystal layer solution of step (1), soaks 5min, then upwards pulls active carbon fiber mat vertically with the speed of 1mm / s, gained product is in Dry at 60°C for 30 minutes, then repeat the above dipping and pulling process 4...

Embodiment 2

[0050] The nano-titanium dioxide / activated carbon fiber mat three-dimensional porous material obtained in embodiment 1 is carried out adsorption and photocatalytic degradation experiment of volatile organic gas toluene:

[0051] (1) Take 4 pieces of nano-titanium dioxide / activated carbon fiber felt three-dimensional porous material (mass about 0.2g) and place them at the bottom of the reaction tank. Then, inject 2 μL, 3.5 μL, and 5 μL of toluene into the reaction tank with a microsampler, respectively. Dark light adsorption was carried out at room temperature and without light for 1.5h, gas samples were collected every 1min, and online content analysis was carried out with INNOVA-1412i infrared photoacoustic chromatography.

[0052] (2) After adsorption equilibrium, turn on the ultraviolet light source (high-pressure mercury lamp, 32W) for photocatalytic degradation experiment, light for 35 hours, collect gas samples every 1 min, and use INNOVA-1412i infrared photoacoustic chr...

Embodiment 3

[0056] (1) Accurately weigh 1.10g of zinc acetate dihydrate (5mmol) into 100mL (1.31mol) of isopropanol (AR), stir at 85°C for 15min, then add 1.4mL (10mmol) of triethylamine (AR ), stirred at 85°C for 5min, and aged at room temperature for 3h to obtain a zinc oxide crystal layer solution.

[0057] (2) Cut the activated carbon fiber felt into 2cm*2cm*1mm (thickness: 1mm, specific surface area 1100m 2 / g) block, dry after pretreatment, with embodiment 1 step (2).

[0058] (3) step (2) is pretreated and dried activated carbon fiber mat is immersed in the zinc oxide crystal layer solution of step (1), soaks 2min, then upwards vertically pulls activated carbon fiber felt at a speed of 5mm / s, and the resulting product is in Dry at 80°C for 1 hour, then repeat the above dipping and pulling process 8 times, put the dried active fiber base in the oven again, and dry it again at 180°C for 4 hours, then zinc oxide crystals can be deposited on the surface of the activated carbon fiber f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com