Verification system and method for ultra-supercritical unit multi-time reheat steam temperature control strategy

An ultra-supercritical unit, reheating steam temperature technology, applied in the control system, superheat temperature control, steam superheating, etc., can solve the problem of limited operating conditions of the unit and can not be arbitrary

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

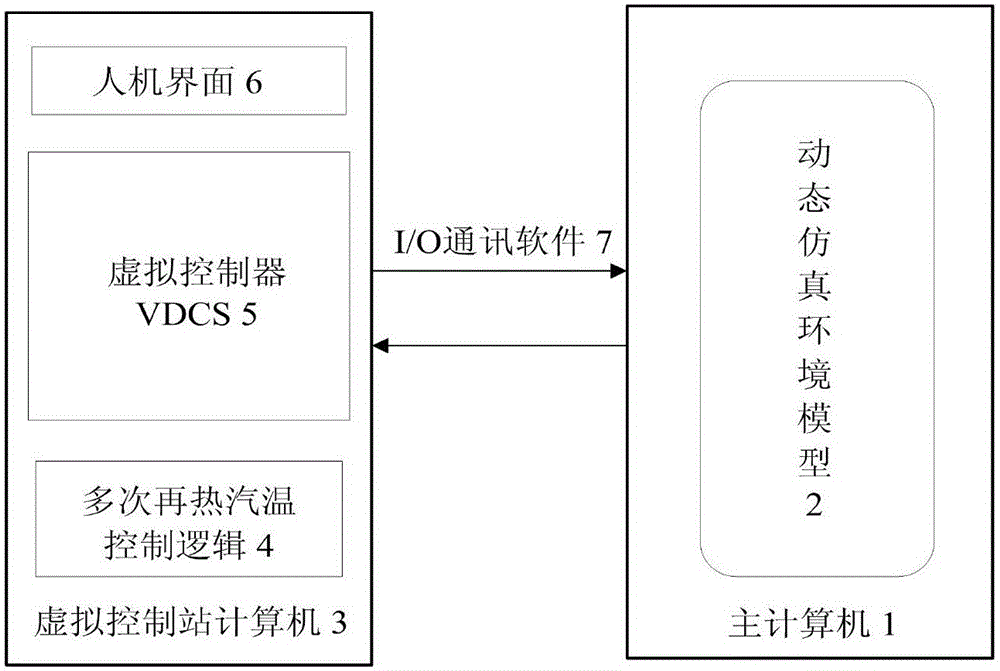

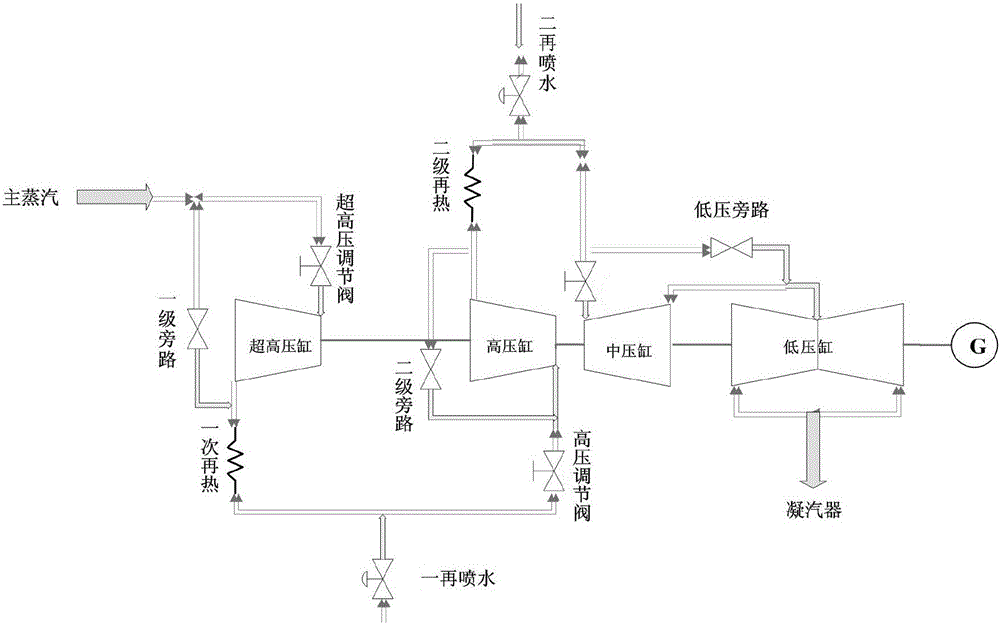

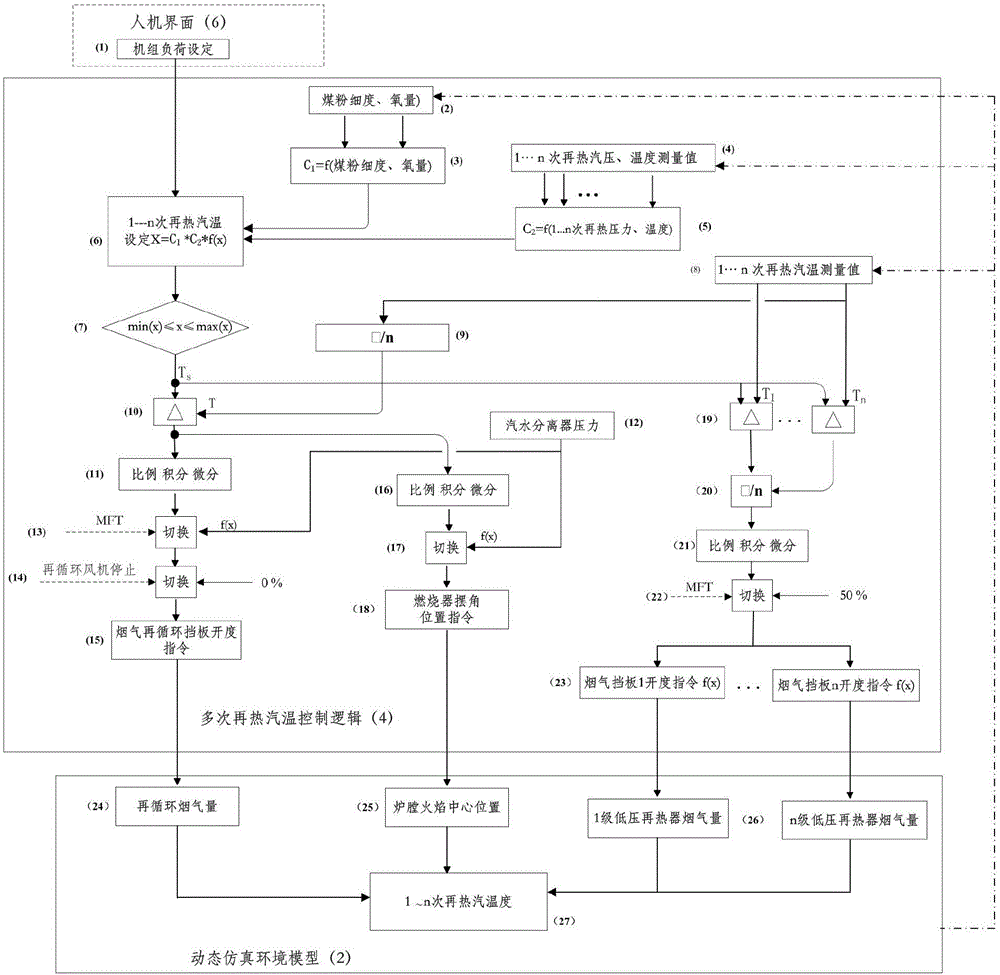

[0081] The boiler of an ultra-supercritical double-reheat unit is a direct-flow Bunsen furnace with two intermediate reheats. The steam turbine adopts the joint start mode of ultra-high / high / medium pressure cylinders, and the main steam is a series process, that is, the main steam enters from the ultra-high pressure cylinder VHP→exhausts to the first-stage reheater→enters the high-pressure cylinder HP→exhausts steam from the high-pressure cylinder HP to Secondary reheater → enter the medium pressure cylinder IP → low pressure cylinder LP → condenser, the steam water flow diagram of the unit is shown in figure 2 . Design the reheat steam temperature control logic of the ultra-supercritical double reheat unit according to the process of the unit, and carry out the real-time dynamic simulation test of the start-up and stop process of the unit through the multi-reheat steam temperature control strategy verification system of the ultra-supercritical unit. According to the flue gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com