Soluble dietary fibers rich in galactomannan and preparation method of soluble dietary fibers

A technology of galactomannan and galactomannan oligosaccharides, which is applied in the field of galactomannan-rich soluble dietary fiber and its preparation, can solve the problems of soluble dietary fiber that have not yet been seen, and achieve great application value and transformation High efficiency and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]A soluble dietary fiber rich in galactomannan, with a weight average molecular weight of 24800 Da, wherein the mass percentage of galactomannan oligosaccharide is 20%-30%, and the polymerization degree of galactomannan oligosaccharide is 2-6.

[0042] The present invention also provides a preparation method of galactomannan-rich soluble dietary fiber, comprising the following steps:

[0043] S1: Preparation of recombinant bacteria containing β-mannanase, wherein the coding gene of β-mannanase is derived from Rhizomucor miehei CAU432;

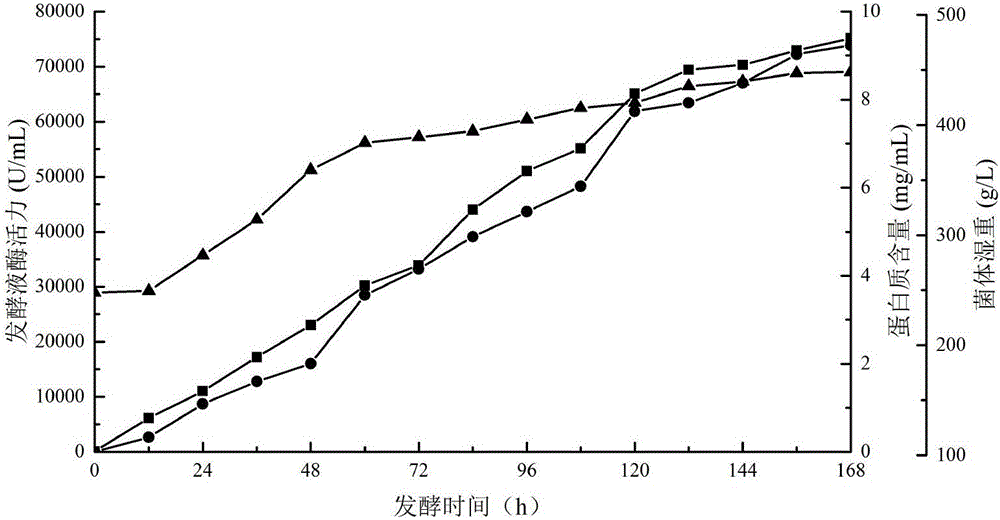

[0044] S2: Microbial fermentation: β-mannanase is prepared by fermentation of recombinant bacteria;

[0045] S3: using β-mannanase to hydrolyze the guar gum solution;

[0046] S4: Filtrating, decolorizing, ion-exchanging and concentrating the enzymolysis solution in step S3 to obtain soluble dietary fiber rich in galactomannan.

[0047] As a preferred implementation of this example, in step S1, the recombinant bacterium is Pichia pastori...

Embodiment 2

[0053] 1. Acquisition of recombinant bacteria

[0054] S1: Using Rhizomucor miehei CAU432cDNA as template, using ManF(5′-CCATG TACGTA GCTTCTTCGTTTGTCCAGACAAG-3′) and ManR (5′-CCG CCTAGG TCACTTCTTGGCCATGGCATC-3′) primer pair, according to the method provided by Polit et al. (Katrolia et al. Journal of Agricultural and Food Chemistry, 2013, 61:394-401) for PCR amplification to obtain PCR amplification products.

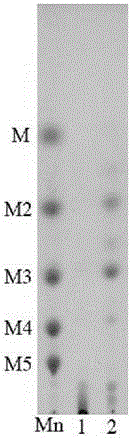

[0055] S2: Perform double enzyme digestion on the PCR amplification product obtained in S1 with restriction endonucleases SnaBI and AvrII, and recover the digested DNA fragments; perform double enzyme digestion on the pPIC9K vector with restriction endonucleases SnaBI and AvrII, Reclaim the backbone vector after the digestion; the DNA fragment is connected with the backbone vector to obtain the recombinant vector A (i.e., between the SnaBI and AvrII restriction sites of the pPIC9K vector, the gene encoding Rhizomucor miehei source β-mannanase is inserted. DNA fragme...

Embodiment 3

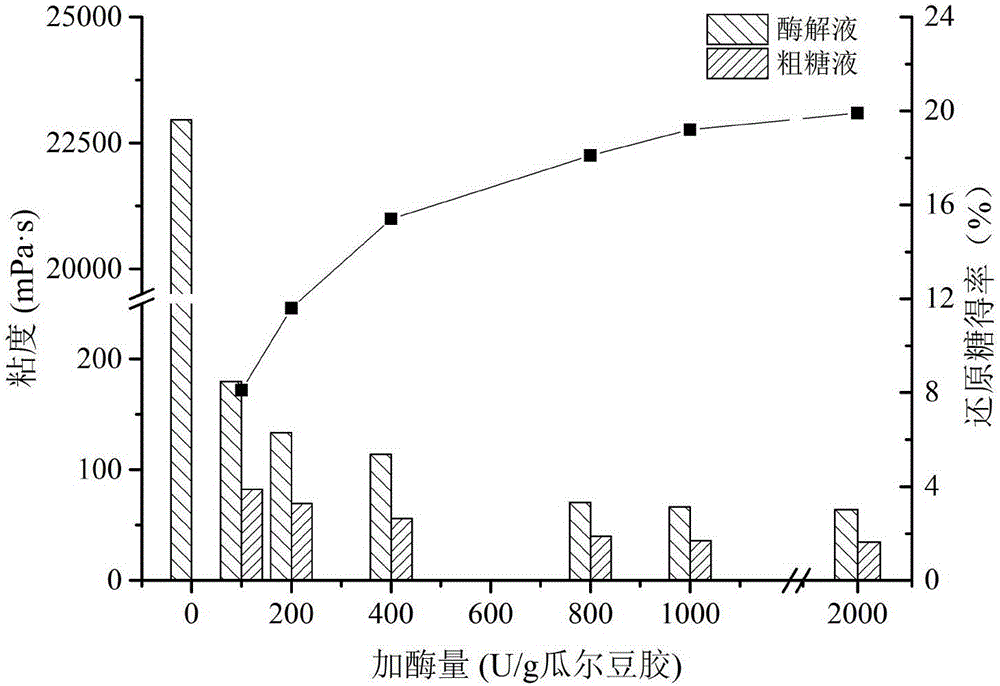

[0079] Example 3, Experimental results of the hydrolysis of guar gum by β-mannanase at different hydrolysis times

[0080] Weigh 5g of guar gum and dissolve it in 100mL of distilled water, add β-mannanase according to the ratio of guar gum to 1000U / g, and place them at 50°C to hydrolyze 1, 2, 4, 8, 12, After 24 hours of enzymolysis, inactivate in a boiling water bath for 10 minutes to obtain an enzymolysis solution, which was centrifuged at 10,000 rpm for 10 minutes, and the supernatant was collected to obtain a crude sugar solution. The viscosity of the crude sugar solution was measured with a DV-1 rotational viscometer at 25°C, and the reducing sugar content in the crude sugar solution was determined by the 3,5-dinitrosalicylic acid method and the yield of reducing sugar was calculated.

[0081] Table 1 shows the viscosity of crude sugar solution and the yield of reducing sugar obtained by hydrolyzing guar gum at different hydrolysis times.

[0082] Table 1 Viscosity of cru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com