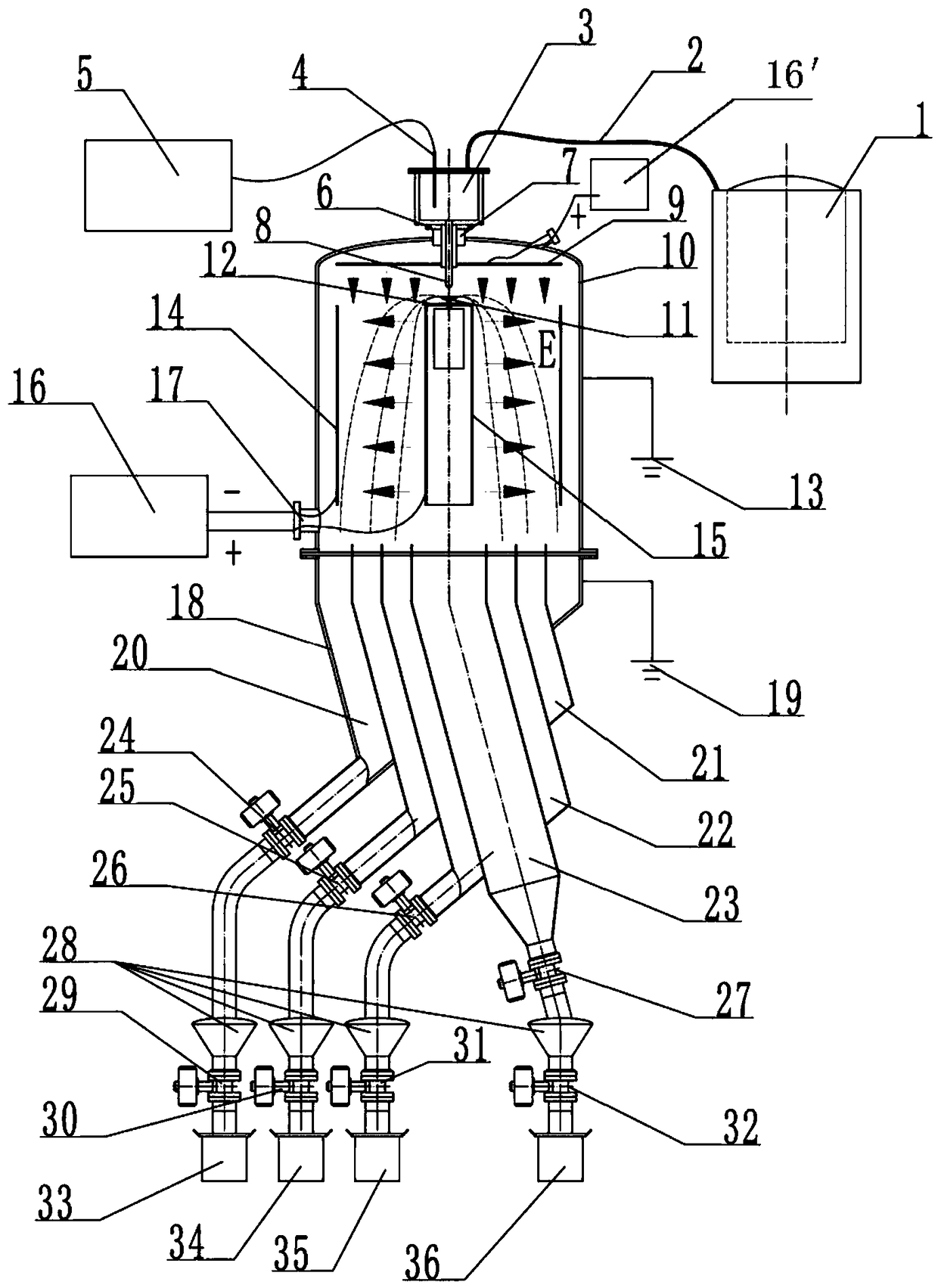

A metal atomization and electric field separation device and method

An electric field and metal technology, which is applied in the field of metal atomization and electric field separation devices, can solve the problems of poor screening effect, easy blockage of the screen, and limitation of preparation time, and achieve high sphericity, small particle size distribution and narrow oxygen concentration. The effect of low content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

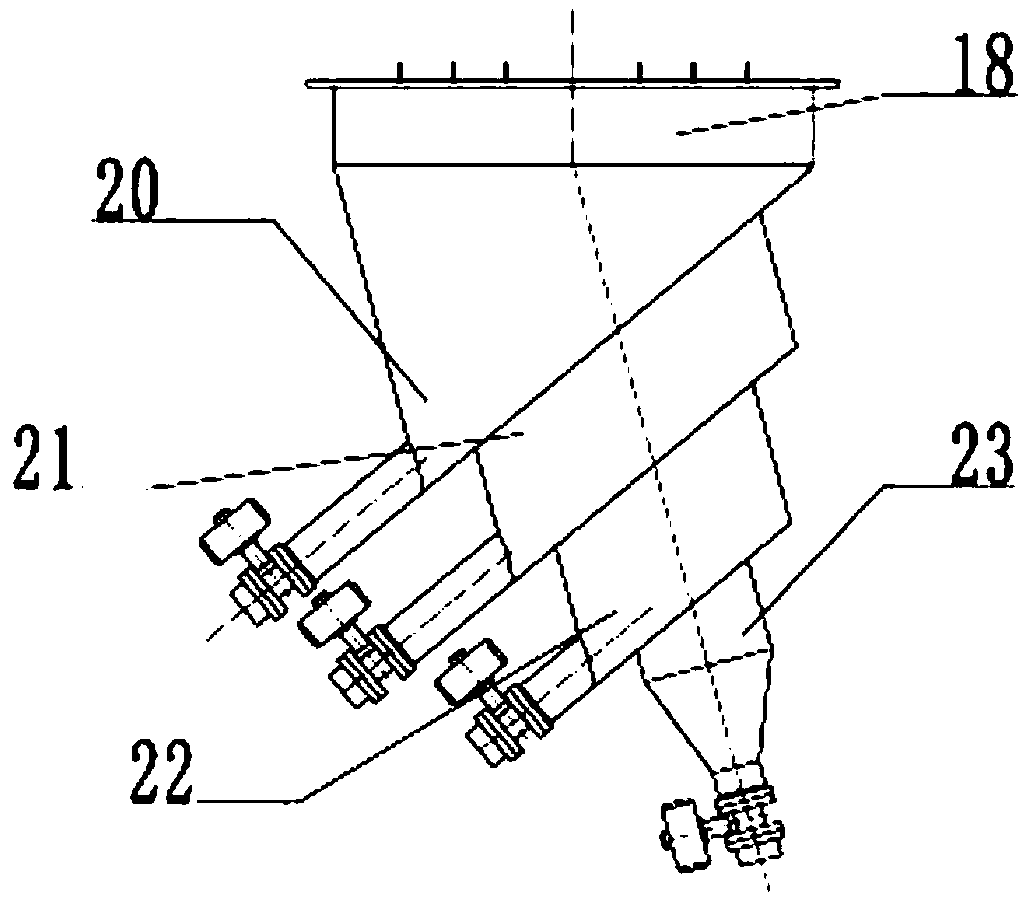

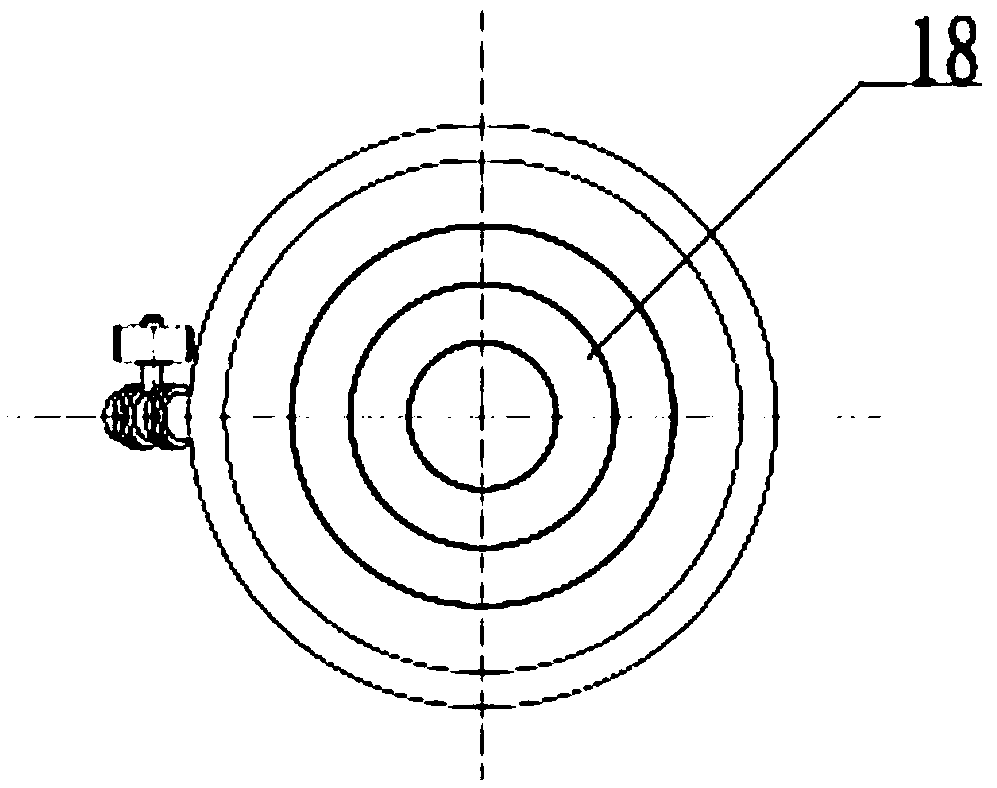

Embodiment 1

[0068] Select Sn, Ag, and Cu to add in the vacuum resistance melting furnace 1 according to the weight ratio of 96.5%, 3%, and 0.5%, and vacuumize the atomizing tank 10, and the vacuum degree reaches 2×10 -2 Pa is filled with inert gas (nitrogen, argon, helium, etc.), so that the pressure of the atomization environment is 0.02MPa, and the oxygen content is 10-400PPm. Then, the molten metal is input into the tundish 3 through the infusion tube 2, the superheat of the molten metal in the tundish 3 is controlled to be 120-160°C, and the charge supply rod 4 is connected with the induction motor generating positive charges to make the molten metal Charges are obtained, and under the action of gravity, the molten metal passes through the guide tube and nozzle flow 8 to the centrifugal atomizer 11, and the molten metal is atomized by an atomizing motor at a speed of 60,000 rpm. After atomization, the charged liquid droplets fly, cool, and solidify under the action of the vertical int...

Embodiment 2

[0070] Select Sn and Bi to add 42% and 58% of Sn and Bi into the vacuum resistance melting furnace 1 according to the weight ratio, and the atomization tank 10 is vacuumized, and the vacuum degree reaches 1×10 -2 Pa is filled with inert gas (nitrogen, argon, helium, etc.), so that the pressure of the atomization environment is 0.02MPa, and the oxygen content is 40-200PPm. Then, the molten metal is input into the tundish 3 through the infusion tube 2, the superheat of the molten metal in the tundish 3 is controlled to be 80-120°C, and the charge supply rod 4 is connected with the induction motor generating positive charges to make the molten metal Charges are obtained, and under the action of gravity, the molten metal flows through the guide tube and nozzle 8 to the centrifugal atomizer 11, and the molten metal is atomized by an atomizing motor at a speed of 50,000 rpm. After atomization, the charged liquid droplets fly, cool, and solidify under the action of the vertical inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com