Two-layer or multilayer composite sheet made of porous metal and high polymer material

A technology of polymer materials and porous metals, applied in the field of composite conductive materials, can solve problems such as misjudgment and key switch function failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

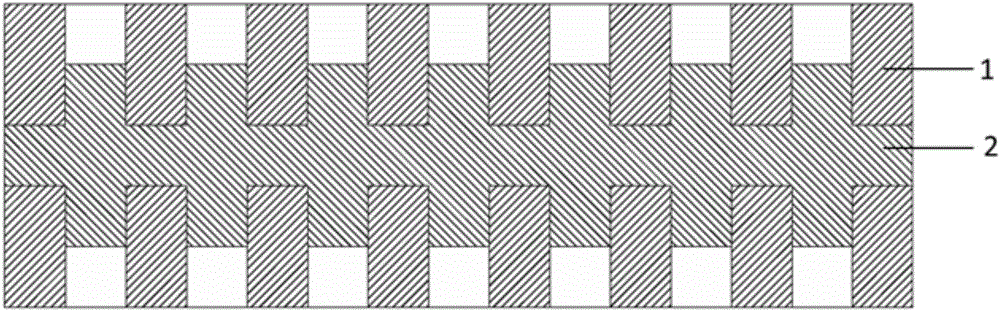

Embodiment 1

[0026] A high-temperature hot-melt adhesive sheet made of epoxy-modified acrylic resin with a thickness of 0.05mm was placed between two porous metal sheets with a thickness of 0.075mm, and pressed at 280°C to obtain a composite sheet. The porous metal sheet used in this embodiment is a stainless steel sheet with uniformly distributed holes with a diameter of 0.5 mm and a distance between two adjacent holes of 0.25 mm. The axes of these holes are perpendicular to the porous metal sheet. The obtained composite sheet was punched into small discs with a diameter of 5 mm. The material of the two circular surfaces of this small disc is the same, and the contact resistance of the two circular surfaces is also the same. This small disc, as an electrical contact, is compounded with silicone rubber by thermal vulcanization and bonding, so that a silicone rubber button with electrical contact can be made. No matter which circular surface of the small disc is bonded to the silicon rubbe...

Embodiment 2

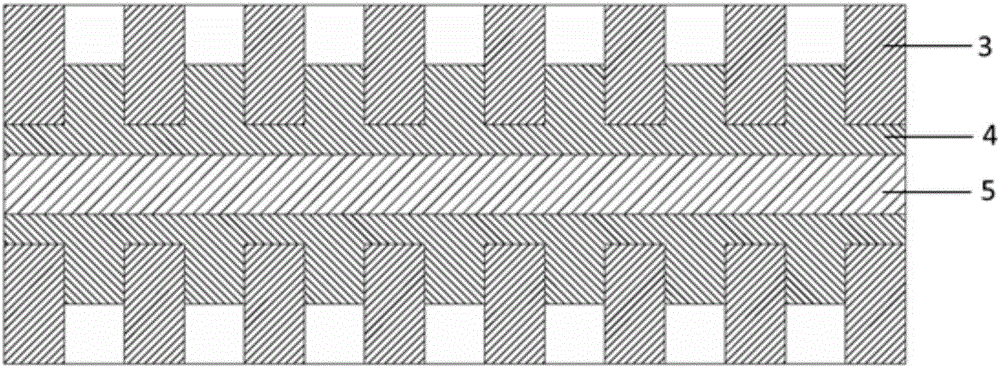

[0029] The materials used in Example 1 were also used in Example 2. In order to increase the overall mechanical strength of the composite sheet and the electrical contacts made afterwards, a non-porous stainless steel sheet with a thickness of 0.075mm is placed between the two layers of porous stainless steel sheets, the non-porous stainless steel sheet and the porous stainless steel sheet Between them, a composite sheet is still bonded with a high-temperature hot-melt adhesive sheet, and die-cut into small discs with various diameters (such as 2mm, 2.5mm, 5mm, 10mm). This small disc can also be used as an electrical contact in a silicone rubber key.

Embodiment 3

[0031] Dip a 0.05mm thick stainless steel sheet into the silicone rubber solution, and coat a layer of silicone rubber with a dry film thickness of 25-30 μm on both sides of the stainless steel sheet by dip coating. The formula of silicone rubber solution is silicone rubber (in this embodiment, select the product produced by Wacker Company, Germany) R401 / 60) 7.5g, vinyltri-tert-butylperoxysilane (VTPS), 0.1g, xylene 92.4g. Dry the silicone rubber solution dip-coated on the stainless steel sheet at 70°C, then, 40-mesh stainless steel wire mesh, 40-mesh nickel wire mesh, 0.15mm thick stainless steel fiber sintered felt with a porosity of 80%, 0.15mm thick Nickel foam with a porosity of 85%, 0.15mm thick nickel expanded mesh with a hole diameter of 0.5mm and a hole spacing of 0.25mm are laminated on both sides of a stainless steel sheet coated with silicone rubber, and then placed on a flat vulcanizer , Pressed at 165°C for 10 minutes to obtain various composite sheets reinfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Circumcircle diameter | aaaaa | aaaaa |

| Circumcircle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com