Sludge curing agent as well as preparation method and use method thereof

A sludge solidifying agent, sludge technology, applied in chemical instruments and methods, sludge treatment, fixed/solidified sludge treatment, etc. Improve compressive strength and dewatering performance, avoid re-pollution of the environment, and reduce the effect of sludge volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

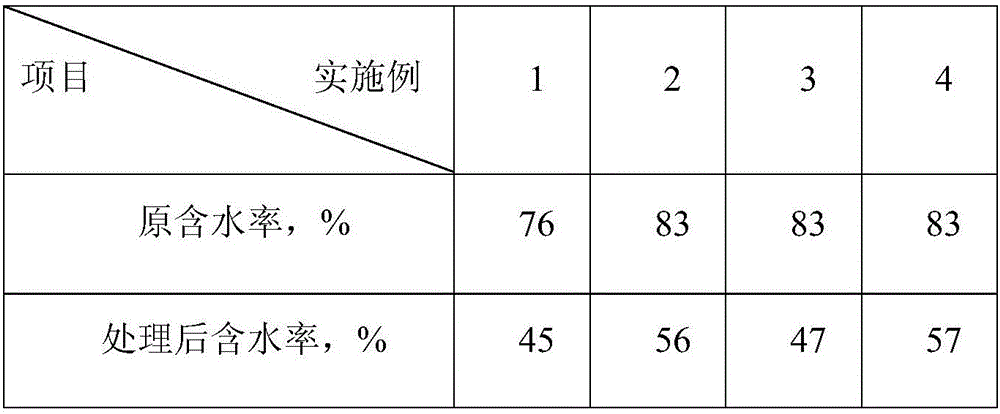

Examples

Embodiment 1

[0044] A kind of sludge curing agent, including liquid composition and solid composition, according to the amount of sludge dosage is 100 tons, the dosage of liquid composition is 4 tons, wherein, the liquid composition includes the following components by weight : 6 parts of sodium silicate, 40 parts of magnesium chloride, 30 parts of ferrous sulfate, 2 parts of organic flocculant, 6 parts of water reducer, 252 parts of water; the organic flocculant is octadecyltrimethylammonium chloride. The dosage of the solid composition is 5 tons, and the solid composition includes the following components in parts by weight: 3 parts of calcium oxide, 1 part of plant ash, 1 part of fly ash, and 2 parts of diatomaceous earth.

[0045] The preparation method of sludge solidification agent comprises the following steps:

[0046] 1) Heat and dry calcium oxide, plant ash, fly ash and diatomaceous earth at 105°C for 9 hours to reduce the moisture content to below 2%;

[0047] 2) Use a pulveriz...

Embodiment 2

[0055] A kind of sludge curing agent, including liquid composition and solid composition, according to the amount of sludge dosage is 100 tons, the dosage of liquid composition is 4 tons, wherein, the liquid composition includes the following components by weight : 4 parts of sodium silicate, 40 parts of magnesium chloride, 30 parts of ferrous sulfate, 2 parts of organic flocculant, 2 parts of water reducer, 200 parts of water; and the dosage of solid composition is 5 tons, and the solid composition includes the following Components in parts by weight: 4 parts of calcium oxide, 2 parts of plant ash, and 1 part of diatomaceous earth.

[0056] The preparation method of sludge solidification agent comprises the following steps:

[0057] 1) Heat and dry calcium oxide, plant ash and diatomaceous earth at 105°C for more than 8 hours to reduce the moisture content to below 2%;

[0058] 2) Use a pulverizer to crush calcium oxide, plant ash and diatomite step by step to less than 1mm ...

Embodiment 3

[0065] A kind of sludge curing agent, including liquid composition and solid composition, according to the amount of sludge dosage is 100 tons, the dosage of liquid composition is 4 tons, wherein, the liquid composition includes the following components by weight : 4 parts of sodium silicate, 30 parts of magnesium chloride, 20 parts of ferrous sulfate, 1 part of organic flocculant, 4 parts of water reducer, 220 parts of water; the dosage of solid composition is 5 tons, and the solid composition includes the following weight Parts of components: 4 parts of calcium oxide, 2 parts of plant ash.

[0066] The preparation method of sludge solidification agent comprises the following steps:

[0067] 1) heating and drying calcium oxide and plant ash at 110°C for 10 hours to reduce the moisture content to below 2%;

[0068] 2) Use a pulverizer to crush calcium oxide and plant ash step by step to less than 1mm respectively, use a ball mill to perform ball milling, crushing, and ball mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com