Borosilicate glass and preparation method

A borosilicate glass and glass technology, which is applied in glass manufacturing equipment, glass pressing, glass forming, etc., can solve the problems of affecting the absorption of heat energy of the glass liquid, weakening the melting capacity of the reactor, and not conforming to green production, etc. To achieve the effect of easy processing and forming, outstanding thermal resistance, excellent mechanical properties and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

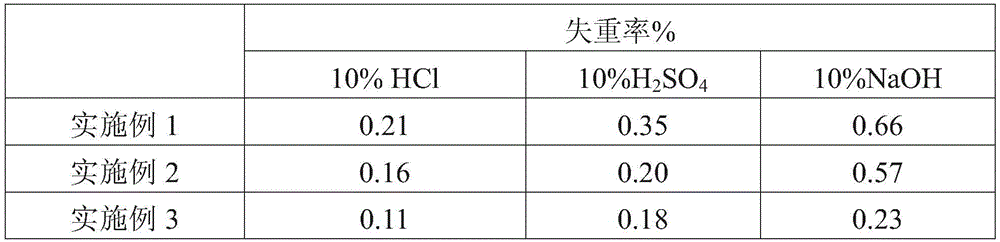

Examples

Embodiment 1

[0041] A kind of borosilicate glass, by weight percentage, its main component comprises: SiO 2 : 54.3%, Al 2 o 3 : 17%, B 2 o 3 : 8%, CaO: 20%, Fe 2 o 3 : 0.2%, TiO 2 : 0.1%, MgO: 0.1% and Na 2 O: 0.3%.

[0042] In terms of weight percentage, the borosilicate glass is mainly made of the following raw materials in weight percentage:

[0043] The borosilicate glass is mainly made of the following raw materials in weight percentage: 52% of pyrophyllite, 12% of kaolin, 10% of quicklime, 14.5% of calcite, 1% of fluorite, 10% of boronite, and 0.2% of mirabilite. %, Soda Ash 0.1%, Carbon Powder 0.2%.

[0044] The method for preparing the above-mentioned borosilicate glass specifically comprises the following steps:

[0045] 1) Take each raw material according to the above weight ratio, dry and pulverize after mixing uniformly, and then pass through a 400-mesh sieve to obtain the micropowder raw material;

[0046] 2) input the micropowder raw material obtained in step 1) in...

Embodiment 2

[0050] A kind of borosilicate glass, by weight percentage, its main component comprises: SiO 2 : 53.85%, Al 2 o 3 : 19.0%, B 2 o 3 : 7.0%, CaO: 18.02%, Fe 2 o 3 : 0.23%, TiO 2 : 0.3%, MgO: 1.0%, Na 2 O: 0.5%; K 2 O: 0.1%.

[0051] The borosilicate glass is mainly made of the following raw materials in weight percentage: 53.8% of pyrophyllite, 11.2% of kaolin, 15.4% of quicklime, 2.9% of fluorite, 15.4% of boronite, 0.6% of mirabilite, and 0.4% of soda ash , Toner 0.3%.

[0052] The preparation method of above-mentioned borosilicate glass specifically comprises the following steps:

[0053] 1) Take each raw material according to the above weight ratio, dry and pulverize after mixing uniformly, and then pass through a 325 mesh sieve to obtain the micropowder raw material;

[0054] 2) input the micropowder raw material obtained in step 1) into a closed tank kiln and melt and react at 1400° C. to form a flowable molten glass;

[0055] 3) Clarifying, defoaming, homogeni...

Embodiment 3

[0058] A kind of borosilicate glass, by weight percentage, its main composition comprises:

[0059] SiO 2 : 59.8%, Al 2 o 3 : 21.3%, B 2 o 3 : 3.3%, CaO: 12.4%, Fe 2 o 3 : 0.2%, TiO 2 : 0.2%, MgO: 0.6%, Na 2 O: 0.2%, K 2 O: 0.2%, BaO 0.8% and ZrO 2 0.8%, Bi 2 o 3 0.2%.

[0060] The borosilicate glass is mainly made of the following raw materials in weight percentage: 56.2% of pyrophyllite, 13% of kaolin, 9.4% of quicklime, 4.5% of fluorite, 10.1% of boronite, 0.8% of mirabilite, and 1.3% of soda ash , Carbon powder 1.6%, barium carbonate 1.7%, zircon 0.5%, bismuth 0.9%.

[0061] The preparation method of above-mentioned borosilicate glass specifically comprises the following steps:

[0062] 1) Take each raw material according to the above-mentioned weight ratio, dry and pulverize after mixing uniformly, and then pass through a 200-mesh sieve to obtain the micropowder raw material;

[0063] 2) Input the micropowder raw material obtained in step 1) into a closed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com