Water reducing agent for concrete

A technology for concrete and water reducing agent, applied in the field of concrete accessories, can solve the problems of low anti-bleeding ability, large conveying resistance, poor anti-freezing ability, etc., and achieves simple and easy-to-master production method, small conveying resistance and good appearance quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

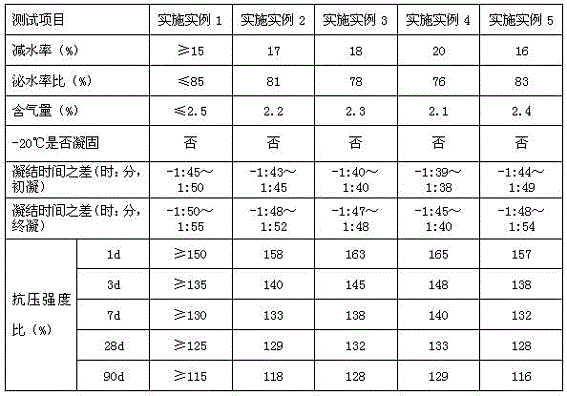

Examples

Embodiment 1

[0030] A water reducing agent for concrete is characterized in that it is composed of the following raw materials in parts by weight:

[0031] Polyethylene glycol: 20 to 35 parts;

[0032] Aminobenzenesulfonic acid: 3 to 5 parts;

[0033] Acrylic acid: 20-40 parts;

[0034] Boric acid: 3 to 5 parts;

[0035] Hydroquinone: 0.5 to 1.5 parts;

[0036] Cyclohexane: 80-120 parts;

[0037] Polyethylene glycol methacrylate: 30-40 parts;

[0038] Ammonium persulfate: 1 to 2 parts;

[0039] Mercaptoethanol: 1 to 2 parts;

[0040] Formaldehyde: 15-25 parts;

[0041] Water glass: 30-50 parts;

[0042] Calcium silicate: 10-16 parts;

[0043] Sodium methacrylate: 6-10 parts;

[0044] Commercially available water-based rust inhibitor JX-502: 5-10 parts;

[0045] Commercially available concrete defoamer of model XWC-2530 or BYC-0852: 5-10 parts;

[0046] Water: 200-300 parts;

Embodiment 2

[0049] A water reducing agent for concrete is characterized in that it is composed of the following raw materials in parts by weight:

[0050] Polyethylene glycol: 20 parts;

[0051] Aminobenzenesulfonic acid: 3 parts;

[0052] Acrylic acid: 20 parts;

[0053] Boric acid: 3 parts;

[0054] Hydroquinone: 0.5 parts;

[0055] Cyclohexane: 80 parts;

[0056] Polyethylene glycol methacrylate: 30 parts;

[0057] Ammonium persulfate: 1 part;

[0058] Mercaptoethanol: 1 part;

[0059] Formaldehyde: 15 parts;

[0060] Water glass: 30 parts;

[0061] Calcium silicate: 10 parts;

[0062] Sodium methacrylate: 6 parts;

[0063] Commercially available water-based antirust agent of model JX-502: 5 parts;

[0064] Commercially available concrete defoamer of model XWC-2530 or BYC-0852: 5 parts;

[0065] Water: 200 parts;

[0066] Sodium hydroxide: 10 parts.

Embodiment 3

[0068] A water reducing agent for concrete is characterized in that it is composed of the following raw materials in parts by weight:

[0069] Polyethylene glycol: 35 parts;

[0070] Sulfuran: 5 parts;

[0071] Acrylic acid: 40 parts;

[0072] Boric acid: 5 parts;

[0073] Hydroquinone: 1.5 parts;

[0074] Cyclohexane: 120 parts;

[0075] Polyethylene glycol methacrylate: 40 parts;

[0076] Ammonium persulfate: 2 parts;

[0077] Mercaptoethanol: 2 parts;

[0078] Formaldehyde: 25 parts;

[0079] Water glass: 50 parts;

[0080] Calcium silicate: 16 parts;

[0081] Sodium methacrylate: 10 parts;

[0082] Commercially available water-based antirust agent of model JX-502: 10 parts;

[0083] Commercially available concrete defoamer of model XWC-2530 or model BYC-0852: 10 parts;

[0084] Water: 300 parts;

[0085] Sodium hydroxide: 30 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water reduction rate | aaaaa | aaaaa |

| gas content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com