Biological organic silicon bacterial fertilizer capable of degrading heavy metals with high efficiency, and preparation method thereof

A technology of heavy metals and organic silicon, applied in the field of bio-agricultural green and environmentally friendly fertilizers, can solve the problems of single function and no substantial breakthrough in potassium solution efficiency, and achieve the effects of enhancing photosynthesis, improving fertilizer utilization rate, and preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

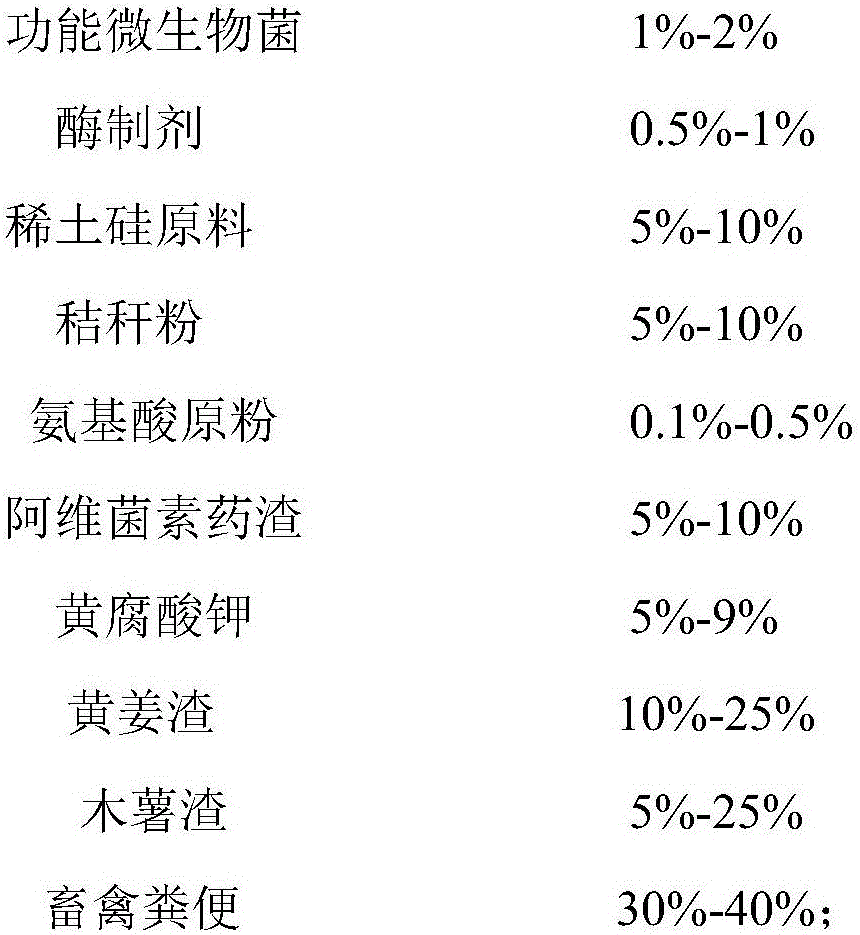

[0059] A bio-organosilicon bacterial fertilizer that efficiently degrades heavy metals is prepared from functional raw materials and water, wherein the functional raw materials are composed of the following components in mass percentage:

[0060]

[0061] The preparation method of the above-mentioned high-efficiency degradation heavy metal bioorganic silicon bacterial fertilizer is as follows:

[0062] 1) Cultivation of fermenting microorganisms:

[0063] Mix and stir the fermenting microorganisms and rice straw powder evenly, and pile them up to form a heap A with a narrow top and a wide bottom, wherein the mass ratio of fermenting microorganisms to rice straw powder is 1:10, and then add 50% of the total mass of amino acid raw powder The former amino acid powder is sprayed on the heap body A with the form of the amino acid former powder solution, and the mass percent concentration of the amino acid former powder solution is 20%. After spraying the amino acid former powder...

Embodiment 2

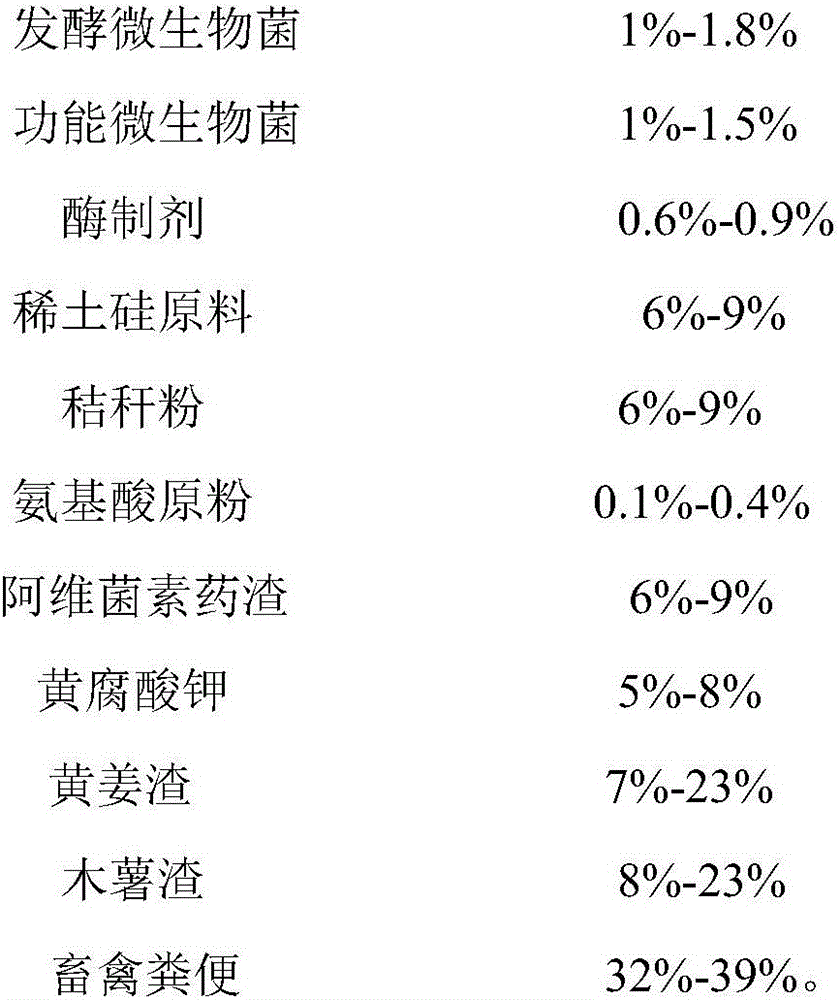

[0073] A bio-organosilicon bacterial fertilizer that efficiently degrades heavy metals is prepared from functional raw materials and water, wherein the functional raw materials are composed of the following components in mass percentage:

[0074]

[0075]

[0076] The preparation method of the above-mentioned high-efficiency degradation heavy metal bioorganic silicon bacterial fertilizer is as follows:

[0077] 1) Cultivation of fermenting microorganisms:

[0078] Mix and stir the fermenting microorganisms and corn stalk powder evenly and pile them up to form a heap A with a narrow top and a wide bottom. The mass ratio of fermenting microorganisms to corn stalk powder is 1:5, and then the The amino acid raw powder is sprayed on the pile A in the form of an aqueous solution, and the mass percentage concentration of the amino acid raw powder solution is 25%. After spraying the amino acid raw powder solution, the water content of the pile A is controlled to be 25%, and the ...

Embodiment 3

[0088] A bio-organosilicon bacterial fertilizer that efficiently degrades heavy metals is prepared from functional raw materials and water, wherein the functional raw materials are composed of the following components in mass percentage:

[0089]

[0090] The enzyme preparation is obtained by mixing cellulase and protease at a mass ratio of 1:1.

[0091] The preparation method of the above-mentioned high-efficiency degradation heavy metal bioorganic silicon bacterial fertilizer is as follows:

[0092] 1) Cultivation of fermenting microorganisms:

[0093] Mix and stir the fermenting microorganisms and wheat straw powder evenly and pile them up to form a heap A with a narrow top and a wide bottom, wherein the mass ratio of fermenting microorganisms to wheat straw powder is 1:15, and then the The amino acid raw powder is sprayed on the pile A in the form of an aqueous solution, and the mass percentage concentration of the amino acid raw powder solution is 30%. After spraying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com