Imidazole-type ionic liquid and application thereof to degradation of polyformaldehyde

A technology of ionic liquid and imidazole type, which is applied in the field of imidazole type ionic liquid and its application in the degradation of polyoxymethylene, can solve the problems of slow degradation of polyoxymethylene, difficult disposal of waste residue, environmental pollution, etc., and achieve consumption saving, thorough decomposition, Effect of reducing solvent volatilization loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

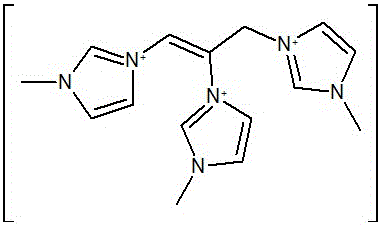

[0026] A kind of imidazole type ionic liquid, its cationic composition is: [ATMIM] 3+ (1,2,3-(3-N-methylimidazolyl)-1-propene), the structural formula is shown in formula (1), and the anion is [p-TSA] - 、[CH 3 COO] - , [HSO 4 ] - , [H 2 PO 4 ] - 、[CF 3 SO 3 ] - 、[CH 3 SO 3 ] - any one or a mixture of two or more;

[0027] Formula 1).

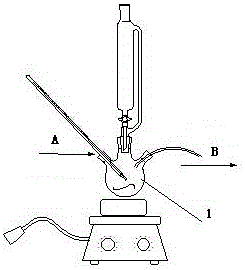

[0028] The preparation method of imidazole type ionic liquid as above may further comprise the steps:

[0029] (1) [ATMIM]Cl 3 Preparation of [1,2,3-(3-N-methylimidazolyl)-1-propene trichloride]: Take 1,2,3-trichloropropene and N-methylimidazole, add to hydrothermal reaction kettle , the molar ratio of the two is 1: (3-6); add 0.1%-1.0% of the raw material mass of γ-alumina and 0.5‰-10‰ of octadecyltrimethylammonium chloride as a catalyst, seal , heated to 220-280°C and stirred for 24-72h, cooled, extracted and purified with ethyl acetate, chloroform, acetone or carbon tetrachloride, and dried to obtain [ATMIM]Cl 3 ;

[00...

Embodiment 2

[0040] The ionic liquid provided by this embodiment is [ATMIM][HSO 4 ] 3 (1,2,3-(3-N-methylimidazolyl)-1-propene trihydrogensulfate), the cation is [1,2,3-(3-N-methylimidazolyl)-1-propene 】 3+ , the anion is [HSO 4 ] - , its preparation method and the method of catalyzing polyoxymethylene are as follows:

[0041] 1. [ATMIM]Cl 3 Preparation of (1,2,3-(3-N-methylimidazolyl)-1-propene trichloride)

[0042]Take 145.41g (1.00mol) of 1,2,3-trichloropropene and 396.45g (4.50mol) of N-methylimidazole, put them into a hydrothermal reaction kettle, add 3.00g of γ-alumina and 1.00g of Octadecyltrimethylammonium chloride, sealed, heated to 280°C and stirred for 48 hours, cooled to room temperature, washed and filtered three times with 400mL ethyl acetate each time, and the white solid obtained was stored in a vacuum drying oven using di Phosphorus was dried at 80°C for 36 hours to finally obtain 254.8 g of a white solid product with a yield of 65.0%.

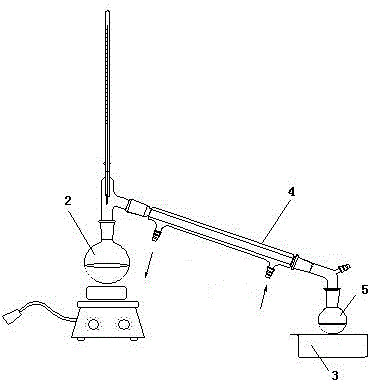

[0043] 2. [ATMIM][HSO 4 ] ...

Embodiment 3

[0047] Except adding 12.0g of polyoxymethylene particles, all the others are the same as in Example 2. Under this condition, the degradation rate of polyoxymethylene is 93.23%, and the formaldehyde is collected to 92.73%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com