TPEE (thermoplastic polyester elastomer)/TPU (thermoplastic polyurethane elastomer)/PTFE (polytetrafluoroethylene) composite cable material and preparation method

A composite cable and elastomer technology, used in insulated cables, plastic/resin/wax insulators, cables, etc., can solve problems affecting the application field of TPEE polyester elastomers, and achieve excellent mechanical properties, chemical solvent resistance The effect of high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

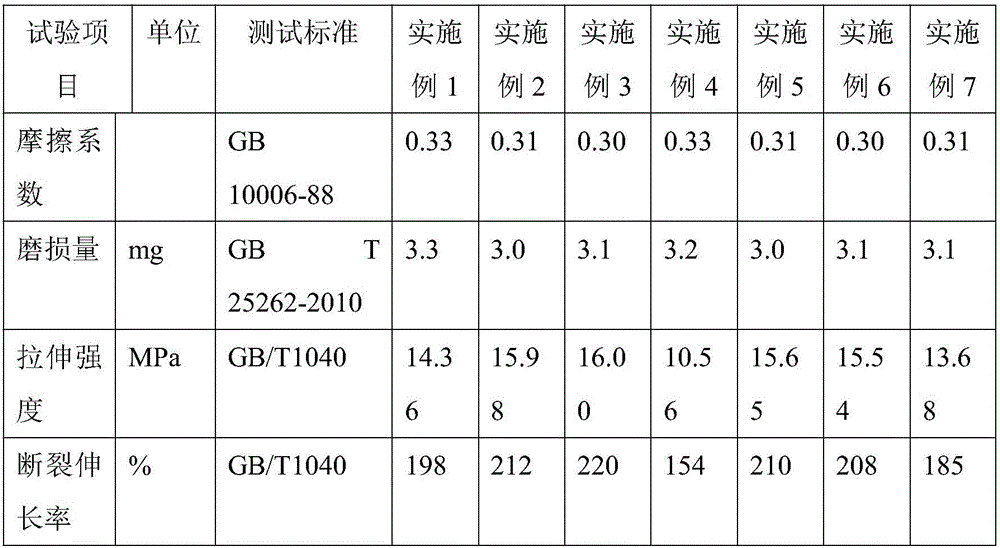

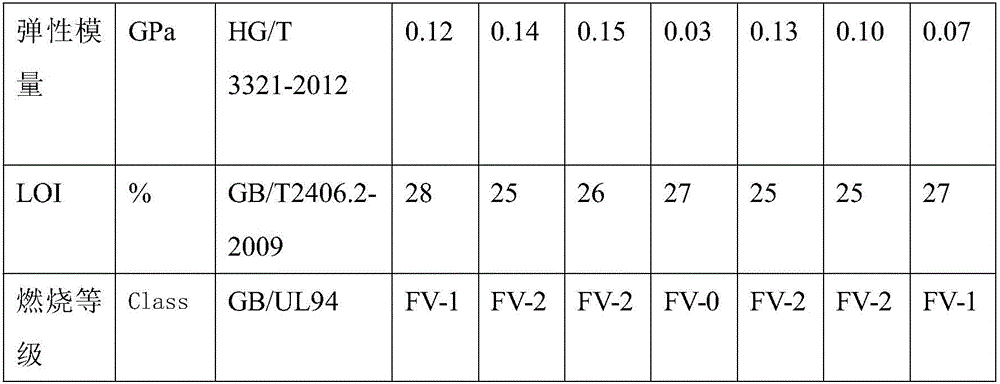

Embodiment 1

[0026] In this embodiment, the raw material composition of the halogen-free flame-retardant super soft wear-resistant TPEE / TPU / PTFE composite cable material includes (wt%): TPEE 35%; TPU 20%; PTFE 5%; MCA 29.5%; Montmorillonite 5% %; polyethylene wax 4%; antioxidant 1680.4%; light stabilizer UV-9 (2-hydroxy-4-methoxybenzophenone) 0.1%, ultraviolet absorber UV-P 2-(2ˊ-hydroxy -5'-methylphenyl)benzotriazole 1%.

Embodiment 2

[0028] In this embodiment, the raw material composition of the halogen-free flame-retardant super soft wear-resistant TPEE / TPU / PTFE composite cable material includes (wt%): TPEE 35%; TPU 20%; PTFE 10%; MCA 24.5%; Montmorillonite 5%; polyethylene wax 4%; antioxidant 1680.4%; light stabilizer UV-9 (2-hydroxy-4-methoxybenzophenone) 0.1%, ultraviolet absorber UV-P 2-(2ˊ- Hydroxy-5'-methylphenyl)benzotriazole 1%.

Embodiment 3

[0030] In this embodiment, the raw material composition of the halogen-free flame-retardant super soft and wear-resistant TPEE / TPU / PTFE composite cable material includes (wt%): TPEE 35%; TPU 20%; PTFE 15%; MCA 24.5%; Montmorillonite 2%; polyethylene wax 2%; antioxidant 1680.4%; light stabilizer UV-9 (2-hydroxy-4-methoxybenzophenone) 0.1%, ultraviolet absorber UV-P 2-(2ˊ- Hydroxy-5'-methylphenyl)benzotriazole 1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com