Detection method of tin content in high concentration tin hydroxide

A tin hydroxide and detection method technology, applied in the field of chemical analysis, can solve problems such as lack of tin, difficult product quality, control, etc., and achieve good reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

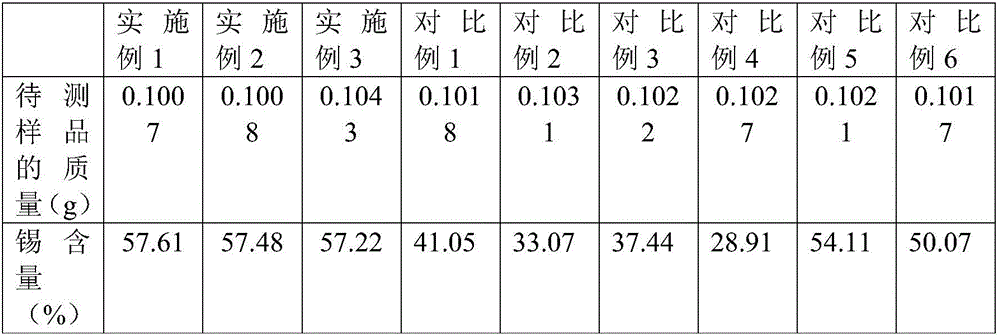

Embodiment 1

[0029] S1. Completely dissolve about 0.1g of the sample to be tested in 20mL of concentrated hydrochloric acid with a mass fraction of 37.5%, heat to 90°C, stir to completely dissolve the sample to be tested, and cool to room temperature (25°C) to form tin chloride to be tested solution;

[0030] S2. Place the solution to be tested obtained in S1 on a stirrer, control the stirring speed to 100 to 200 r / min, add dilute hydrochloric acid solution equivalent to 5 times the volume of the solution to be tested, and obtain a mixed solution;

[0031] S3. Weigh about 6g of zinc powder (60 times the mass of the sample to be tested), divide it into 3 parts on average, and add it to the mixed solution of S2 in 3 times. The interval between each addition of zinc powder is 10min. The process of adding zinc powder In the process, use a glass liquid seal tube filled with saturated sodium bicarbonate solution to prevent air from entering. After the reaction is complete, heat the solution to 6...

Embodiment 2

[0036] Follow the steps of Example 1, except that in S1, heat to 80°C.

Embodiment 3

[0038] According to the steps of Example 1, the difference is that in S3, 6g of zinc powder (60 times the mass of the sample to be tested) was weighed, divided into 2 parts on average, and added to the mixed solution of S2 in 2 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com