Small organic molecule donor material based double-junction solar cell device and preparation method thereof

A small molecule donor, solar cell technology, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of few devices, backward photoelectric conversion performance, lack of preparation technology, etc., and achieve good reproducibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

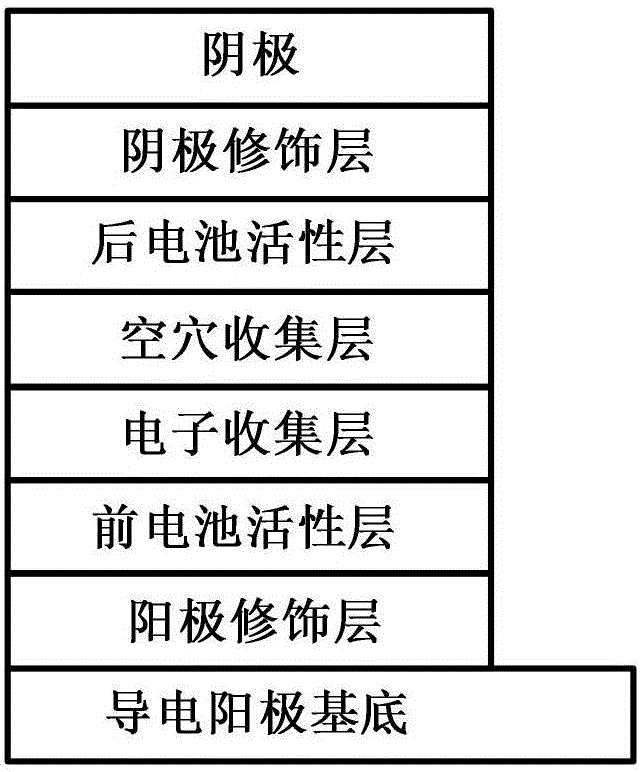

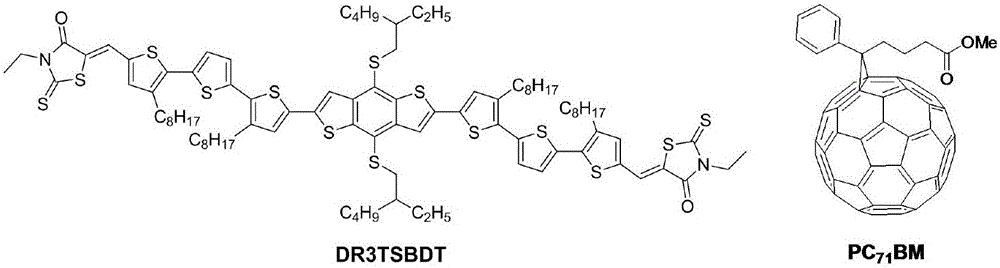

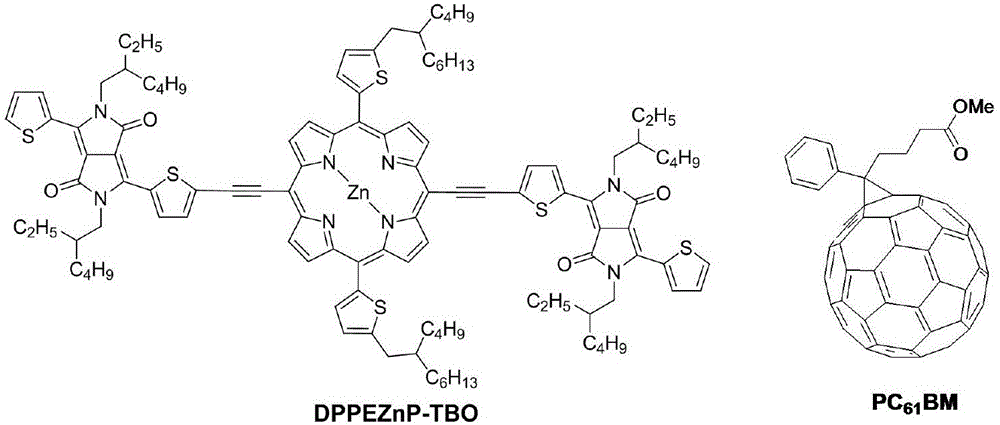

[0037] A double-junction solar cell device based on an organic small molecule donor material, such as figure 1 As shown, including conductive anode ITO glass, cuprous thiocyanide anode modification layer, front cell active layer, zinc oxide electron collection layer, neutral PEDOT:PSS hole collection layer, rear cell active layer, PFN cathode modification layer and aluminum The cathode constitutes a laminated structure, and the thickness of each layer is: ITO anode 110-130nm, copper thiocyanide anode modification layer 35-40nm, front battery active layer 120-130nm, zinc oxide electron collection layer 38-42nm, neutral PEDOT: PSS hole collection layer 38-42nm, rear battery active layer 120-130nm, PFN cathode modification layer 4.5-5.5nm, aluminum cathode 60-80nm.

[0038] The preparation method of the double-junction solar cell device based on the organic small molecule donor material comprises the following steps:

[0039] 1) The ITO glass was ultrasonically cleaned with det...

Embodiment 2

[0057] Double-junction organic solar cell device, the specific structure is the same as in Example 1, such as figure 1 shown.

[0058] The difference from Example 1 is that the material of the anode modification layer is changed to molybdenum oxide, and the materials and dimensions of the other layers are exactly the same as those of Example 1.

[0059] The preparation method of the double-junction organic solar cell device comprises the following steps:

[0060] 1) Indium tin oxide glass (ITO) was ultrasonically cleaned with detergent, deionized water, acetone, and isopropanol solvents for 15 minutes each. After taking it out, it was blown dry with a nitrogen gun, and treated in an ultraviolet ozone cleaner for 20 minutes.

[0061] 2) spin coating molybdenum oxide anode modification layer on the pretreated ITO glass

[0062] An ethanol solution of molybdenum oxide was prepared, spin-coated on the conductive anode substrate to form a film with a thickness of about 35 nm, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com