Novel environment-friendly pig house and pollution-free intensive pig farming method

A pig house, a new type of technology, applied in the field of pig breeding, can solve the problems of difficult discharge, easy disease, and inability to seal, and achieves the effect of less floor space, strong function and reasonable arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

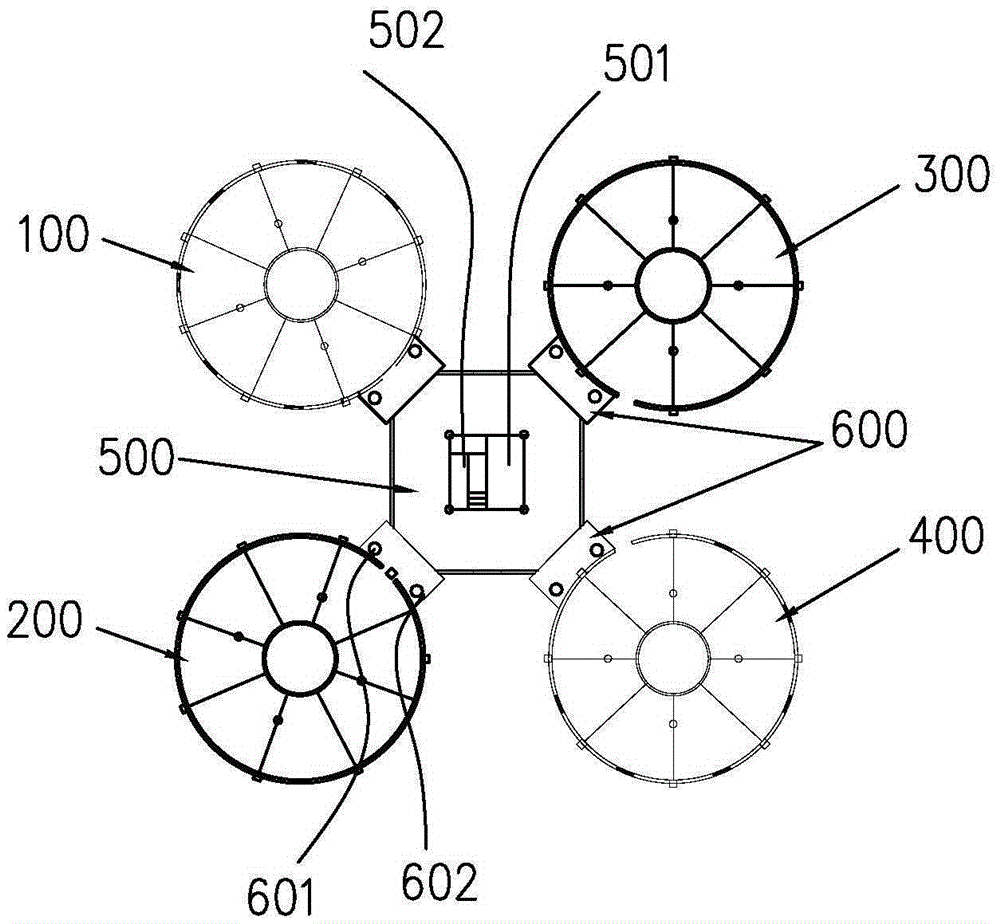

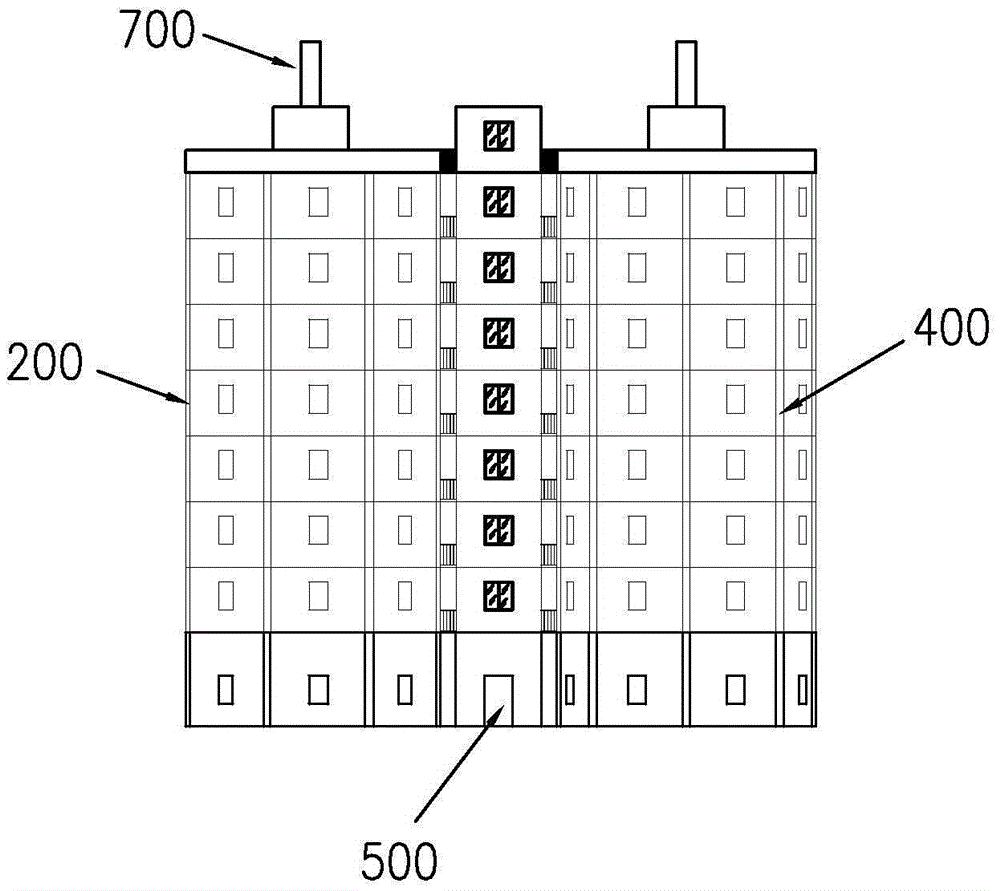

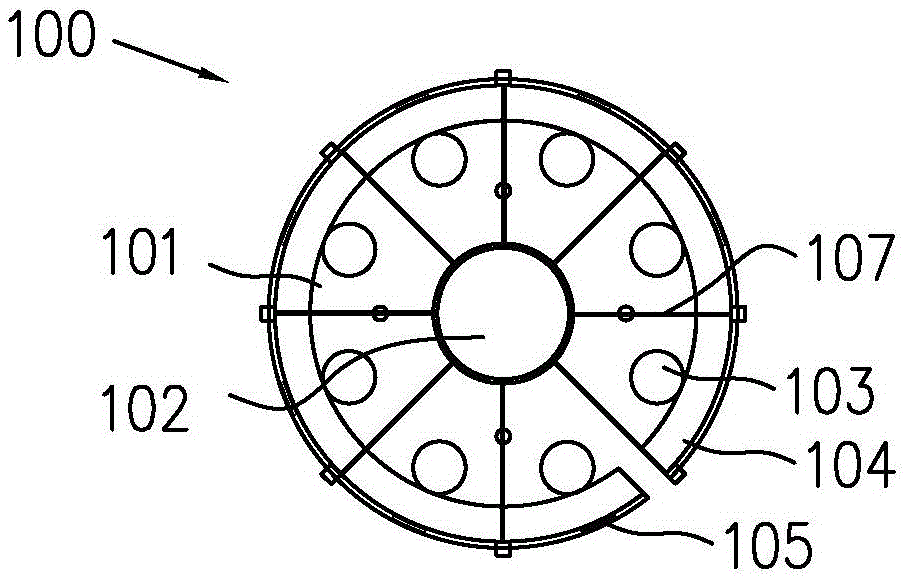

[0031] see figure 1 and figure 2 , the pig house of the present invention comprises four circular buildings, respectively the first pig house building 100, the second pig house building 200, the third pig house building 300 and the fourth pig house building 400. These 4 pig house buildings are arranged as Square, and the shape and structure of each building are consistent. In the middle of these four pig house buildings, passage and auxiliary facility building 500 are provided, and passage and auxiliary facility building 500 are provided with elevator room 501 and step room 502 . The pig house building, passage and auxiliary facility building adopt reinforced concrete frame structure, and the passage and auxiliary facility building is octahedral. The first pig house building 100, the second pig house building 200, these 4 buildings of the third pig house building 300 and the fourth pig house building 400 form a breeding unit with passage and auxiliary facility building 500....

Embodiment 2

[0042] Pig house of the present invention comprises four circular buildings equally. These 4 pig house buildings are arranged in a square shape, and the shape and structure of each building are consistent. There are passages and auxiliary facilities buildings in the middle of the four pig house buildings, and the passages and auxiliary facilities buildings are equipped with elevator rooms and stair rooms.

[0043] These four pig house buildings are all 8 floors, and there are connecting parts between the passage and auxiliary facility buildings and each pig house building, so that each floor of each pig house building can be horizontally connected with the passage and auxiliary facility buildings. Each connection part is provided with a ventilation pipe and a feed delivery pipe, which can respectively deliver the wind and the feed to each floor of the pig house. There is an exhaust gas collection and treatment device on the top of each pig house building.

[0044] The differ...

Embodiment 3

[0051] Pig raising method of the present invention is:

[0052] If it is pig breeding (piglets are fed into big pigs for sale), adopt the structure of Embodiment 1, and the piglets are first raised in the first pig house building 100 for about 75 days, and then directly transferred to other three medium and large pig house buildings on the same floor. farming. Due to the corresponding quantity, it just happens to be all transferred, no need to go up and down the stairs. After the transfer, the first pig house building 100 can replenish a batch of piglets to form a production line.

[0053] If it is sow breeding, the structure of Embodiment 2 is adopted. The pregnant sow building 800 is used to feed pregnant sows. The sows are transferred to the delivery sow building 900 on the same floor for 7 days before delivery. After the piglets are weaned, The sows are moved into the comprehensive building, and the piglets continue to be fed for 7-15 days before being transferred

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com