Activated water reaction device

A technology of reaction device and activated water, which is applied in the field of water treatment, can solve the problems of activated water supply, inconvenient storage, inconvenient use, cumbersome process, etc., and achieve the improvement of dissolved oxygen and antibacterial ability, long life and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

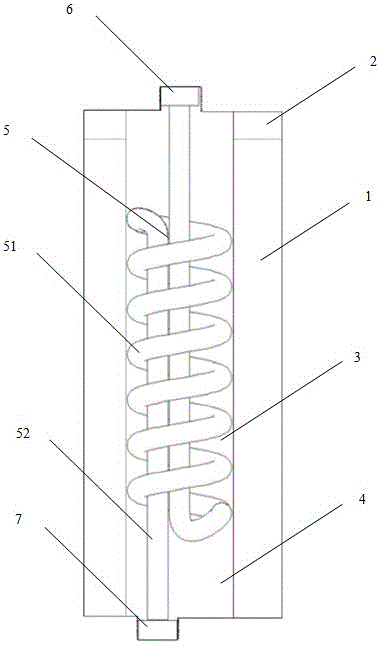

[0029] Such as figure 1 As shown, a kind of activated water reaction device 3 is made of main body 1, protective cover 2 and reaction device 3, protective cover 2 is screw-connected on the top of main body 1, and described reaction device 3 is installed in main body 1 inside, is characterized in that: The reaction device 3 includes a filter element body 4, and the inside of the filter element body 4 is provided with a multi-turn reaction channel 5, and a water molecule activation material is installed in the multi-turn reaction channel 5.

[0030] The main body 1 is provided with a water inlet 6, which communicates with the entrance of the multi-turn reaction channel 5, and the protective cover 2 is provided with a water outlet 7, which is connected with the multi-turn reaction channel 5. The outlet is connected, and the water inlet 6 and the water outlet 7 are respectively provided with threaded joints.

[0031] The multi-turn reaction channel 5 includes a spiral coil 51, th...

Embodiment 2

[0062] The water molecule activation material is made of the following raw materials in weight percentage:

[0063] Calcium carbonate 65.0-90%, dipotassium oxide 1.0-10%, ferric oxide 0.5-5%, calcium oxide 0.1-5%, titanium dioxide 0.1-2%, silicon dioxide 0.05-2%, sulfur trioxide 0.01- 2%, manganese oxide 0.01-2%, barium oxide 0.005-2%, strontium 0.005-2%, rubidium oxide 0.001-1%, copper oxide 0.001-1%, and diyttrium oxide 0.001-0.005%.

[0064] The preparation technology of described water molecule activation material is:

[0065] A. Weighing, crushing and mixing: Weigh calcium carbonate, dipotassium oxide, ferric oxide, calcium oxide, titanium dioxide, silicon dioxide, sulfur trioxide, manganese oxide, barium oxide, strontium, rubidium oxide by weight percentage , copper oxide, yttrium trioxide, mixed and crushed, the mixed powder is a nano-powder with a particle size of 70nm, to obtain the mixed powder of the required water molecule activation material;

[0066] B. Molding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com