Protein peptide with antioxidant activity and preparation method thereof

An antioxidant activity and protein peptide technology, which is applied in the field of protein peptides with antioxidant activity and its preparation, can solve the problems of high ash content of products and affect the flavor of products, and achieves industrialized production, good flavor and thermal stability, The effect of good functional features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

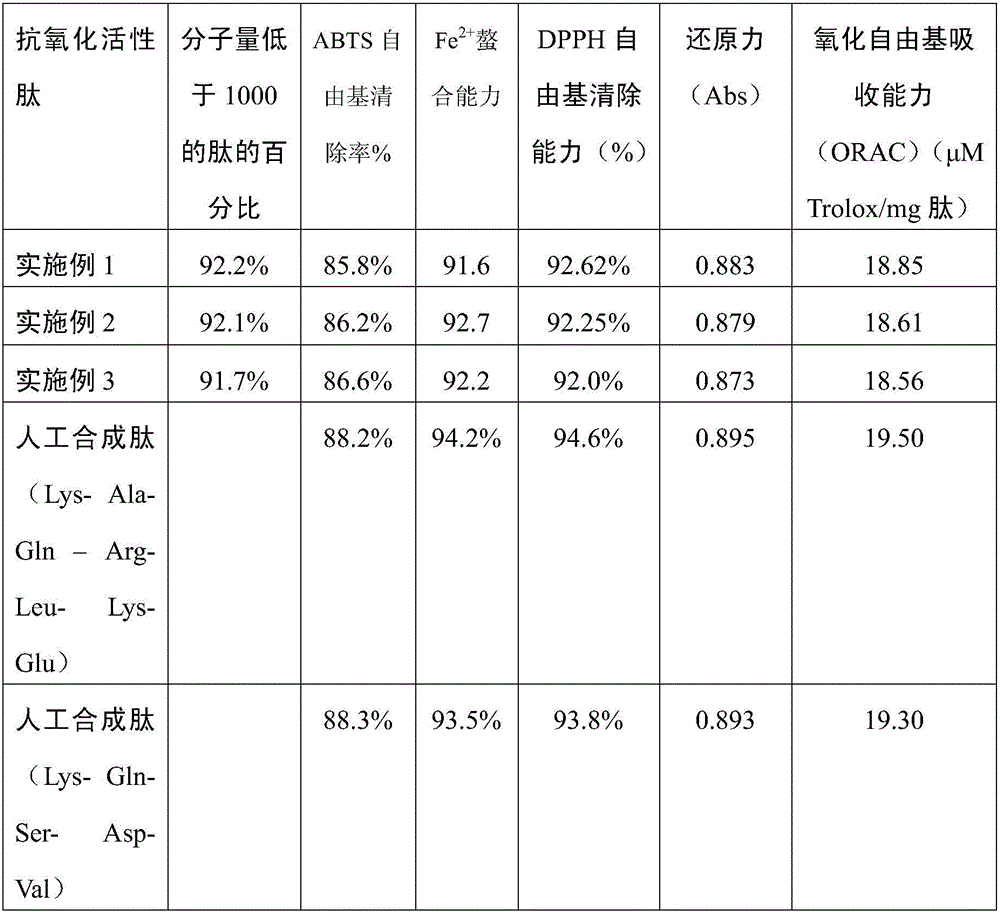

Embodiment 1

[0036] Example 1 Preparation of Bighead Carp Meat Antioxidant Active Peptide

[0037] (1) Wash 100 grams of bighead carp meat, beat the fish meat with a beater to obtain fish meat pulp; then add 150 grams of water 1.5 times the weight of fish meat to the fish meat slurry, bathe in water at 95°C for 20 minutes, and then disperse The homogenizer was homogenized for 2 minutes at 10000 rpm to obtain 250 grams of fish slurry. By centrifuging at 6000g for 10-min, the upper layer of fat was removed to obtain 230 grams of fat-free fish meat slurry. The temperature of the degreased fish meat slurry was adjusted to 55° C., and treated with ultrasonic waves (frequency 35 kH) in an ultrasonic generator for 15 minutes.

[0038] (2) Adjustment step (1) The temperature of the fish meat slurry is 55°C, and then the compound protease is added according to the ratio of the compound protease to the fish meat mass ratio of 1:300 (alkaline protease: flavor protease: bromelain = 2:1:1) 0.33 g, en...

Embodiment 2

[0042] Example 2 Preparation of Bighead Carp Meat Antioxidant Active Peptide

[0043](1) Wash 500 grams of bighead carp meat, beat the fish meat with a beater to obtain fish meat pulp; then add 1,000 grams of water 2.0 times the weight of fish meat to the fish meat slurry, bathe in water at 90°C for 20 minutes, and then disperse The homogenizer was homogenized for 2 minutes at 12000 rpm to obtain 1500 grams of fish slurry. By centrifuging at 8000g for 10min, the upper layer of fat was removed to obtain 1430 grams of fat-free fish meat slurry. The temperature of the degreased fish meat slurry was adjusted to 60° C., and treated with ultrasonic waves (frequency 45 kH) in an ultrasonic generator for 20 minutes.

[0044] (2) Regulating (1) the temperature of the fish meat slurry is 60 DEG C, then according to the composite protease (alkaline protease: flavor protease: bromelain=2:2:1) and fish mass ratio is 1:400 to add composite protease 1.25 grams, Enzymolysis at 65°C for 3 ho...

Embodiment 3

[0048] Preparation of Example 3 Cod Meat Antioxidant Active Peptide

[0049] (1) Wash 1000 grams of cod meat, beat the fish meat with a beater to obtain a fish meat paste; then add 2000 grams of water 2.0 times the weight of the fish meat to the fish meat paste, bathe in water at 90 ° C for 15 minutes, and use a dispersing homogenizer The machine was homogenized at 12000rpm for 2min to obtain 3000 grams of fish slurry. By centrifuging at 6000g for 15min, the upper layer of fat was removed to obtain 2880 grams of fat-free fish meat slurry. The temperature of the degreased fish meat slurry was adjusted to 60° C., and treated with ultrasonic waves (frequency 40 kH) in an ultrasonic generator for 15 minutes.

[0050] (2) Regulating step (1) The temperature of the fish meat slurry is 65°C, then add 2.5 grams according to the compound protease (alkaline protease: flavor protease: bromelain = 3:1:1) and fish meat mass ratio of 1:400, Enzymolysis was performed at 65°C for 4 hours, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com