A method for removing and recovering copper from magnesium ammonium phosphate sludge

A technology for removing copper from magnesium ammonium phosphate, which is applied to the improvement of process efficiency, photographic process, instruments, etc., can solve the problems of high processing cost, incomplete copper removal, residues, etc., so as to simplify the process flow, save the cost of chemicals, reduce the cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

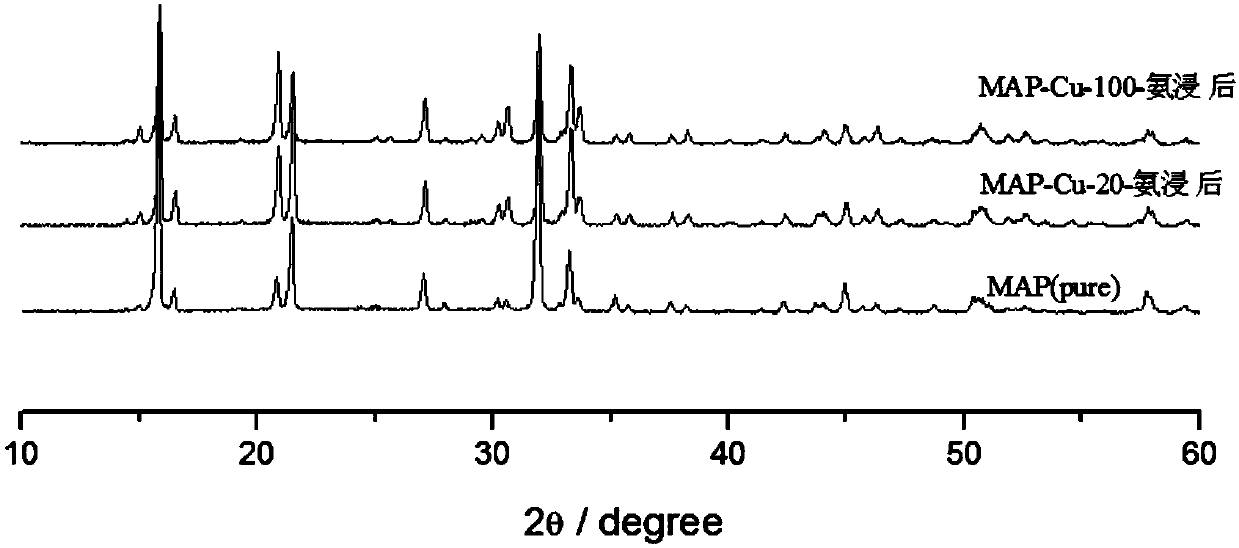

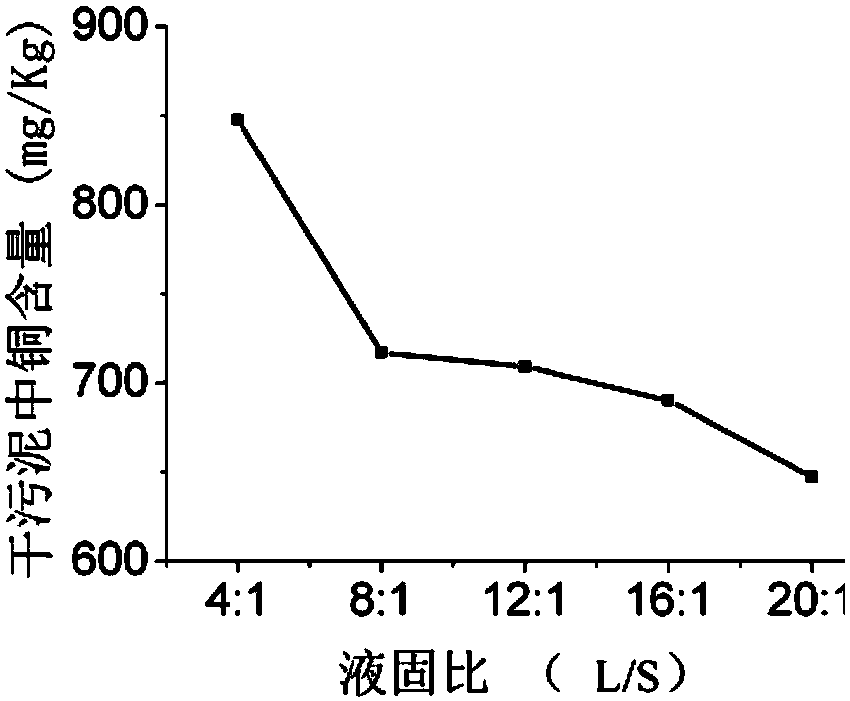

[0036] For wastewater with a copper content of 20 mg / L and an ammonia nitrogen content of 333 mg / L, add phosphate and magnesium salt in a ratio of n(N):n(P):n(Mg)=1:1:1, and use sodium hydroxide Adjust the pH value to 9.5 to react magnesium ammonium phosphate, stir for 1 hour, and filter to obtain a precipitate. After testing, the copper content in the precipitate was 2920mg / kg. It is 6 times the limit value of copper in the "Standards for the Control of Pollutants in Agricultural Sludge" (GB4282-84). Add ammonium carbonate to 8-12mol / L concentrated ammonia water to prepare ammonia immersion solution, and control the molar ratio of ammonium salt to ammonia water to be (0.5-2):1. The ammonia immersion solution was mixed with the magnesium ammonium phosphate precipitation, the liquid-solid ratio was 18:1, and oscillated and leached in a closed container. After 2 hours, it was taken out and filtered. The copper content in the magnesium ammonium phosphate sludge after ammonia lea...

Embodiment 2

[0038]For wastewater with a copper content of 100 mg / L and an ammonia nitrogen content of 333 mg / L, add phosphate and magnesium salt in a ratio of n(N):n(P):n(Mg)=1:1:1, and use sodium hydroxide The pH value was adjusted to 9.5 for ammonium magnesium phosphate reaction, stirred for 1 hour, and filtered to obtain a precipitate. After testing, the copper content in the precipitate was 17849mg / kg. It is 18 times the limit value of copper in the "Standards for the Control of Pollutants in Agricultural Sludge" (GB4282-84). Add ammonium sulfate to 8-12mol / L concentrated ammonia water to prepare ammonia immersion solution, and control the molar ratio of ammonium salt to ammonia water to be (0.5-2):1. The ammonia immersion solution was mixed with the magnesium ammonium phosphate precipitation, and the liquid-solid ratio was 16:1. The liquid-solid ratio was 16:1, and the vibration leaching was carried out in a closed container. After 2 hours, it was taken out and filtered. The copper ...

Embodiment 3

[0040] For wastewater with a copper content of 100mg / L and a phosphorus content of 737mg / L, add phosphate and magnesium salt in a ratio of n(N):n(P):n(Mg)=1:1:1, and use sodium hydroxide to Adjust the pH to 10 for ammonium magnesium phosphate reaction, stir for 1 h, and filter to obtain a precipitate. After testing, the copper content in the precipitate was 17602mg / kg. It is 35 times the limit value of copper in the "Standards for the Control of Pollutants in Agricultural Sludge" (GB4282-84). Add ammonium carbonate to 8-12mol / L concentrated ammonia water to prepare ammonia immersion solution, and control the molar ratio of ammonium salt to ammonia water to be (0.5-2):1. Mix the ammonia immersion solution with the magnesium ammonium phosphate precipitation, the liquid-solid ratio is 10:1, shake and leaching in a closed container, take it out and filter after 2 hours, the copper content in the precipitation is measured to be 410mg / L. The copper content in the treated magnesium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com