High-strength high-flexibility CuNiSn alloy material and preparation method thereof

An alloy material and high-elasticity technology, which is applied in the field of new high-strength and high-elasticity CuNiSn alloy material and its preparation, can solve the problems of poor stress relaxation resistance at high temperature, limitation, unsuitable for long time, etc., and achieve excellent fatigue resistance and good cold working characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

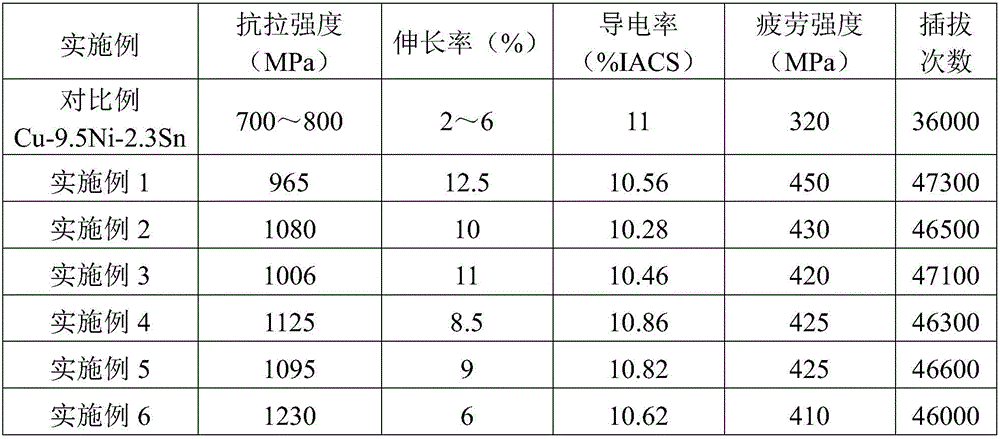

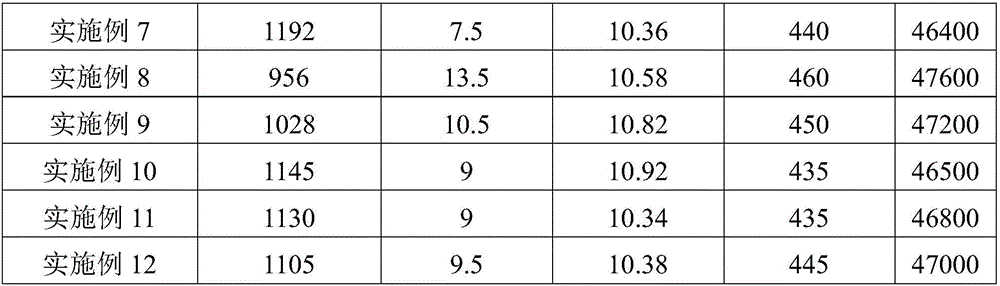

Examples

preparation example Construction

[0027] The preparation and processing technology of the copper alloy described in the present invention are: a. batching, feeding, smelting and casting according to the mass percentage, b. solution annealing, c. milling, d. rough rolling, e. trimming, f .Intermediate annealing, g. Pickling, h. Intermediate rolling, i. Solution annealing + surface cleaning, j. Finish rolling, k. Aging, l. Pickling, m. Stretch bending straightening, n. Split shearing, o .Packaging and storage.

[0028] The alloy of the present invention adopts the following raw materials for smelting: electrolytic copper, industrial pure nickel, pure tin, pure silicon, copper-manganese alloy, copper-niobium alloy and copper-zirconium alloy.

Embodiment 1

[0030] The composition of the alloy is shown in Example 1 of Table 1.

[0031] 1. Melting: Melting is carried out in a non-vacuum environment using a power frequency induction furnace. The order of adding the alloy is: first add copper (Cu), after melting, then add nickel (Ni), cobalt (Co), vanadium (V), copper-boron alloy (Cu-B), and then add tin (Sn ), add copper-phosphorus (Cu-P) alloy after it is completely melted, and after the composition test is qualified and the slag is cleaned, it is covered with baked charcoal; the melting temperature is 1250°C, and the casting temperature is controlled at 1180°C.

[0032] 2. Solution annealing: Place the billet in a bell-type annealing furnace for solution annealing, the annealing temperature is 800°C, and the holding time is 3h.

[0033] 3. Face milling: face milling of the alloy (0.8mm milling on the upper and lower surfaces).

[0034] 4. Rough rolling: the alloy strip after face milling is cold-rolled and billeted, and the tota...

Embodiment 2

[0042] The composition of the alloy is shown in Example 2 of Table 1.

[0043] 1. Melting: Melting is carried out in a non-vacuum environment using a power frequency induction furnace. The order of adding the alloy is: first add copper (Cu), after melting, then add nickel (Ni), cobalt (Co), vanadium (V), copper-boron alloy (Cu-B), and then add tin (Sn ), add copper-phosphorus (Cu-P) alloy after it is completely melted, after the composition test is qualified and the slag is cleaned, it is covered with baked charcoal; the melting temperature is 1230°C, and the casting temperature is controlled at 1170°C.

[0044] 2. Solution annealing: Place the billet in a bell-type annealing furnace for solution annealing, the annealing temperature is 800°C, and the holding time is 3h.

[0045] 3. Face milling: face milling of the alloy (0.8mm milling on the upper and lower surfaces).

[0046] 4. Rough rolling: the alloy strip after face milling is cold-rolled and billeted, and the total pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| fatigue strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com