Cresylic reisn containing high wear resistance drum type brake pad and manufacturing method

A technology of cresol resin and brake pads, which is applied in the field of high wear-resistant drum brake pads to achieve the effects of less dust falling, no corrosion of the wheel hub, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

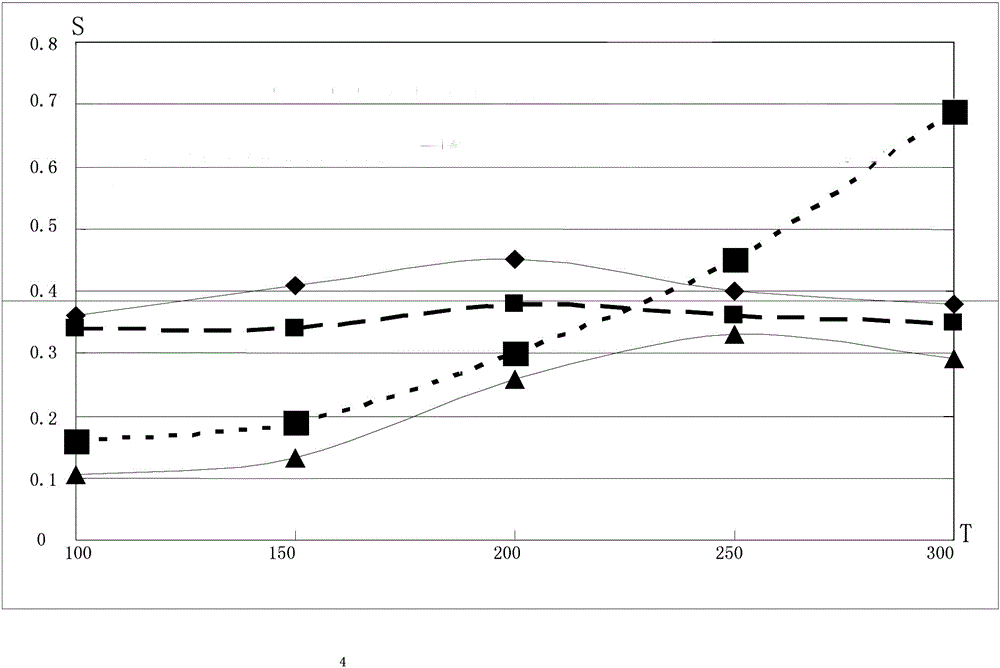

Image

Examples

Embodiment Construction

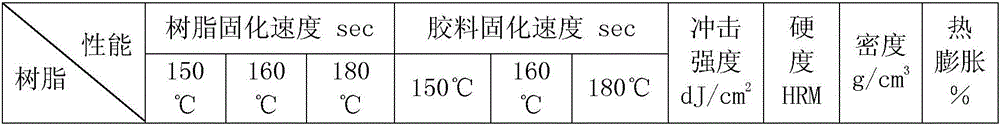

[0041]The following is a further description of the formulation and manufacturing technology of a high wear-resistant drum brake pad containing cresol resin provided by the present invention.

[0042] 1. The formula and combination of ceramic-like friction materials are divided into two components, A and B, which are described in terms of total weight percentage. The component A includes: precipitated barium sulfate 15-28%; aramid pulp ≤ 3%; whiskers Fiber 15-25%; graphite 15-22%; component B includes: cresol resin binder 8-16%; alkali-free E-glass fiber ≤ 3%; antimony trisulfide 1-4%; copper powder 2-6%; powdered nitrile 2-6%; mica 1-5%; ceramic fiber 5-10%. Wherein, whisker fiber is the combination of artificial calcium carbonate whisker and natural acicular wollastonite whisker, and its weight ratio is 1:1.2-1.5; Graphite is the combination of artificial graphite, natural graphite and expanded graphite, and its weight ratio is 1:1. : 1: 1.5-2.

[0043] Mixed cresol resin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific wear rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com