Nano Ni (OH)2@C composite material and preparation method

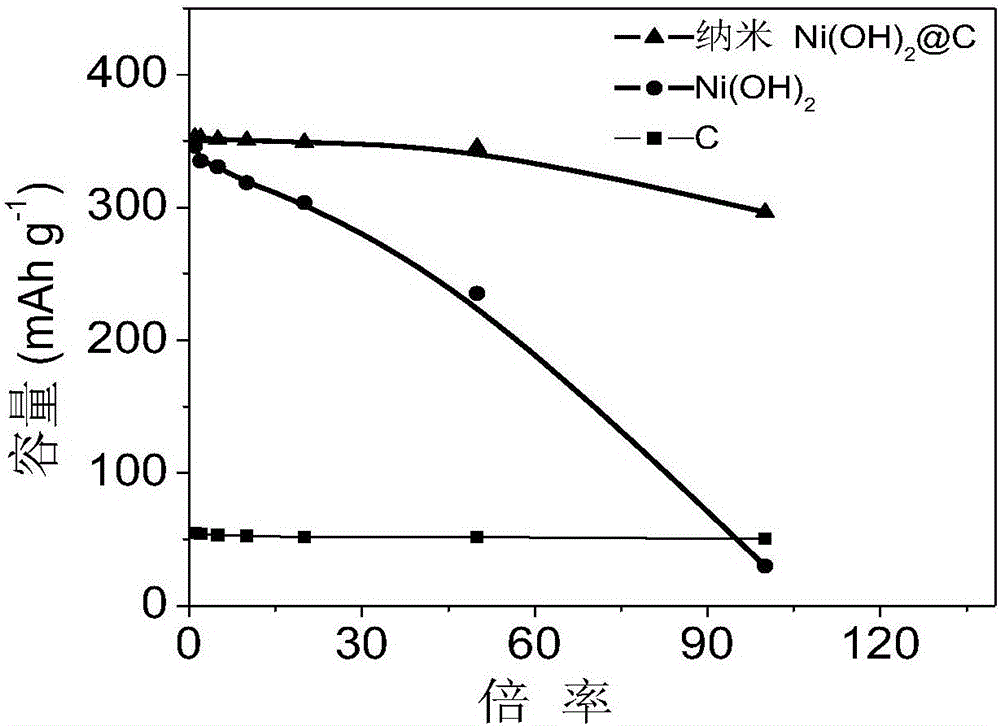

A composite material and nanotechnology, applied in the field of nanocomposite materials and electrochemistry, can solve problems such as high cost and complicated preparation methods, and achieve the effect of shortening charging time and increasing specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

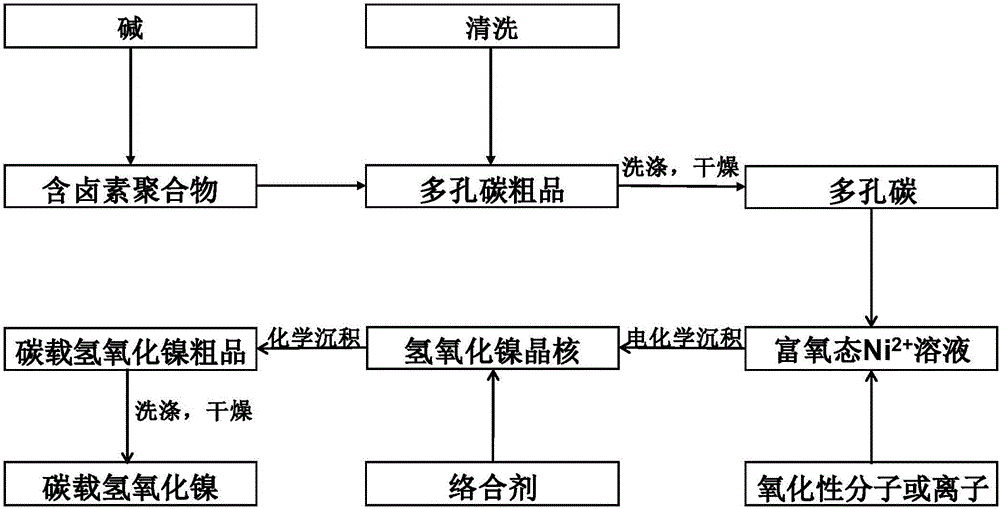

[0041] according to figure 1 The process route of the present embodiment is as follows:

[0042] 1. Preparation of Carbon Supports

[0043] Weigh 3g of polyvinylidene chloride (PVDC) and 10g of NaOH by ball milling in a ball mill at 60 rpm for 6 hours. The resulting solid mixture was calcined at 600°C for 3 h in a nitrogen atmosphere to obtain a porous carbon crude product, and then sequentially washed with 1 mol L -1 dilute hydrochloric acid and deionized water, and finally vacuum-dried at 120 °C for 3 h to obtain a porous carbon sample. 2. Nano Ni(OH) 2 Preparation of @C composite materials

[0044] First configure 80mL containing 0.2mol L -1 NaClO and 1.2mol L -1 The oxygen-enriched nickel ion solution of nickel sulfate is standby for solution A, configure 50ml of 1mol L -1 Aqueous ammonia is used as solution B, and 20ml of a mixed solution containing 4mol / L NaOH and 2.4mol / L ammonia is prepared as solution C for subsequent use.

[0045] (1) Electrochemical precipit...

Embodiment 2

[0051] according to figure 1The process route, the implementation process of this example is as follows:

[0052] 1. Preparation of Carbon Supports

[0053] Weigh 3g of polyvinyl fluoride and 10g of KOH by ball milling in a ball mill at 50 rpm for 8 hours. The obtained solid mixture was calcined at 350°C for 7h in a nitrogen atmosphere to obtain a porous carbon crude product, and then sequentially washed with 1mol L -1 dilute nitric acid and deionized water, and finally vacuum-dried at 100 °C for 5 h to obtain a porous carbon sample.

[0054] 2. Nano Ni(OH) 2 Preparation of @C composite materials

[0055] First configure 80mL containing 0.3mol L -1 H 2 o 2 and 1.2mol L -1 The oxygen-enriched nickel ion solution of nickel sulfate is standby for solution A, configure 35ml of 1.5mol L -1 The ammonium sulfate was used as solution B for later use, and 20 ml of a mixed solution containing 2.4 mol / L LiOH and 1.5 mol / L ethylenediamine was prepared as solution C for later use....

Embodiment 3

[0062] according to figure 1 The process route, the implementation process of this example is as follows:

[0063] 1. Preparation of Carbon Supports

[0064] Weigh 2.5g of polyvinylidene chloride (PVDC) and 8g of NaOH by ball milling in a ball mill at 60 rpm for 6 hours. The resulting solid mixture was calcined at 800°C for 2 h in a nitrogen atmosphere to obtain a crude porous carbon, and then sequentially washed with 1 mol L -1 dilute sulfuric acid and deionized water, and finally vacuum-dried at 150 °C for 2.5 h to obtain a porous carbon sample.

[0065] 2. Nano Ni(OH) 2 Preparation of @C composite materials

[0066] First configure 80mL containing 0.3mol L -1 CrO 3 and 1.1mol L -1 The oxygen-enriched nickel ion solution of nickel sulfate is standby for solution A, configure 65ml of 0.8mol L -1 The ethylamine solution is used as solution B for later use, and 20 ml of a mixed solution containing 4mol / L KOH and 2.4mol / L ammonia water is prepared as solution C for later...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com