Method of assembling MOF/nitrogen-doped active carbon asymmetric supercapacitor device

A technology of supercapacitor and activated carbon, which is applied in the manufacture of hybrid/electric double-layer capacitors, electrodes of hybrid capacitors, etc., can solve the problems of volume expansion, collapse of microstructure, poor cycle performance, etc., to reduce internal resistance, good cycle performance, The effect of increasing the specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

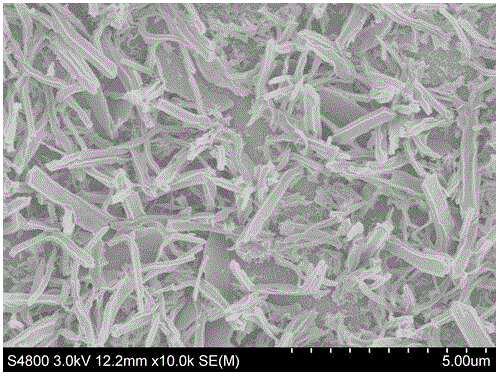

[0015] (1) Mix and stir cobalt nitrate aqueous solution and 2-methylimidazole aqueous solution at room temperature to synthesize MOF, code name zif-67, wash with ultrapure water and analytical pure ethanol at 60 °C for 5 times, and then vacuum dry at 80 °C After 24 h, the obtained purple powder was heated at a heating rate of 1 °C / min to 300 °C in an air atmosphere for 1 h, and then cooled to room temperature at a cooling rate of 5 °C / min to obtain a supercapacitor cathode material.

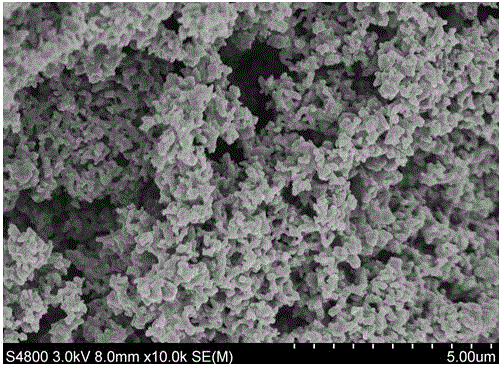

[0016] (2) Mix aniline, phytic acid, and ammonium persulfate aqueous solution in an ice-water bath to prepare polyaniline hydrogel, then soak the polyaniline hydrogel in deionized water for 24 h, take it out and freeze-dry it for 24 h, and then dry it at 2 ℃ / The heating rate of min was raised to 400 °C and calcined for 30 min in an argon atmosphere to prepare carbonized hydrogel. The carbonized hydrogel was soaked in 6 M KOH, and then dried. The resulting mixture was heated at 5 °C / min The heati...

Embodiment 2

[0020] (1) Mix and stir cobalt nitrate aqueous solution and 2-methylimidazole aqueous solution at room temperature to synthesize MOF, code name zif-67, wash with ultrapure water and analytical pure ethanol at 60 °C for 5 times, and then vacuum dry at 80 °C After 24 h, the obtained purple powder was heated at a heating rate of 1 °C / min to 300 °C in an air atmosphere for 1 h, and then cooled to room temperature at a cooling rate of 5 °C / min to obtain a supercapacitor cathode material.

[0021] (2) Mix aniline, phytic acid, and ammonium persulfate aqueous solution in an ice-water bath to prepare polyaniline hydrogel, then soak the polyaniline hydrogel in deionized water for 24 h, take it out and freeze-dry it for 24 h, and then dry it at 2 ℃ / The heating rate of min was raised to 400 °C and calcined for 30 min in an argon atmosphere to prepare carbonized hydrogel. The carbonized hydrogel was soaked in 6 M KOH, and then dried. The resulting mixture was heated at 5 °C / min The heati...

Embodiment 3

[0025](1) Mix and stir cobalt nitrate aqueous solution and 2-methylimidazole aqueous solution at room temperature to synthesize MOF, code name zif-67, wash with ultrapure water and analytical pure ethanol at 60 °C for 5 times, and then vacuum dry at 80 °C After 24 h, the obtained purple powder was heated at a heating rate of 1 °C / min to 300 °C in an air atmosphere for 1 h, and then cooled to room temperature at a cooling rate of 5 °C / min to obtain a supercapacitor cathode material.

[0026] (2) Mix aniline, phytic acid, and ammonium persulfate aqueous solution in an ice-water bath to prepare polyaniline hydrogel, then soak the polyaniline hydrogel in deionized water for 24 h, take it out and freeze-dry it for 24 h, and then dry it at 2 ℃ / The heating rate of min was raised to 400 °C and calcined for 30 min in an argon atmosphere to prepare carbonized hydrogel. The carbonized hydrogel was soaked in 6 M KOH, and then dried. The resulting mixture was heated at 5 °C / min The heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com