Doped stannic oxide and graphene composite material and preparing method thereof

A technology of graphene and tin oxide, which is applied in the field of one-step in-situ preparation of doped tin oxide graphene composite materials and its preparation, can solve the problems of poor rate performance, insufficient binding force, and poor conductivity of negative electrode materials, and achieve synthesis Low cost, low cost, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

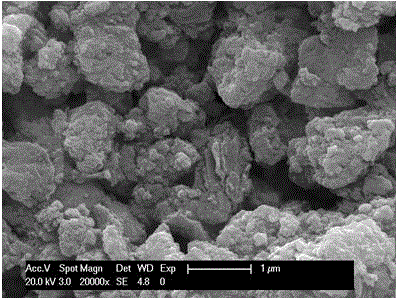

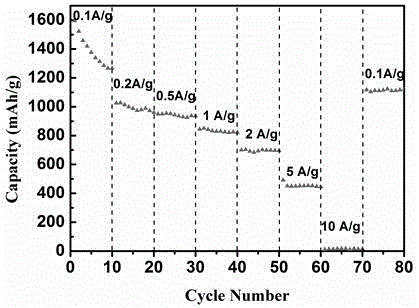

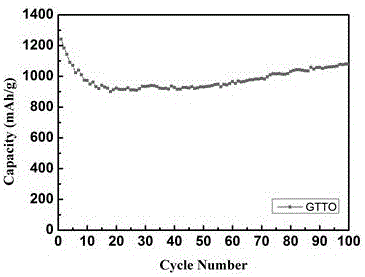

[0032] Example 1: Weigh 0.1 g of graphene oxide, evenly disperse it in 40 mL of water, add 0.5 g of stannous oxalate, stir for 1 hour, mix 4.3 mg of tungsten powder and 90 μL of hydrogen peroxide (the precursor of tungsten needs to use hydrogen peroxide) Add it after mixing, ultrasonically disperse for 2 hours, transfer to a hydrothermal kettle, add 30 mL of water, and react at 170°C for 24 hours. After cooling, the product was taken out, washed with water and ethanol several times, and vacuum-dried at 140° C. for 12 hours to obtain a tungsten-doped tin oxide graphene composite. The specific capacity of the above composite negative electrode material is about 1100 mAh / g.

Embodiment 2

[0033] Example 2: Weigh 0.06g of graphene oxide, uniformly disperse in 40 mL of ethanol, add 0.4g of stannous oxalate and 0.19g of ammonium fluoride, stir for 0.5h, ultrasonically disperse for 1h, transfer to a hydrothermal kettle, add 30 mL of water, react at 100°C for 48h. After cooling, the product was taken out and washed several times with water and ethanol, and dried in vacuum at 120° C. for 18 hours to obtain a fluorine-doped tin oxide graphene composite. The specific capacity of the above-mentioned composite negative electrode material is about 1000 mAh / g.

Embodiment 3

[0034] Example 3: Weigh 0.12 g of graphene oxide, uniformly disperse in 40 mL of water, add 1 g of stannous oxalate, stir for 1.5 h, add 31.5 mg of antimony trichloride, ultrasonically disperse for 2 h, transfer to a hydrothermal kettle, add 30 mL of water, react at 160°C for 48h. After cooling, the product was taken out, washed with water and ethanol several times, and vacuum-dried at 150° C. for 10 h to obtain an antimony-doped tin oxide graphene composite. The specific capacity of the above composite negative electrode material is about 1100 mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com