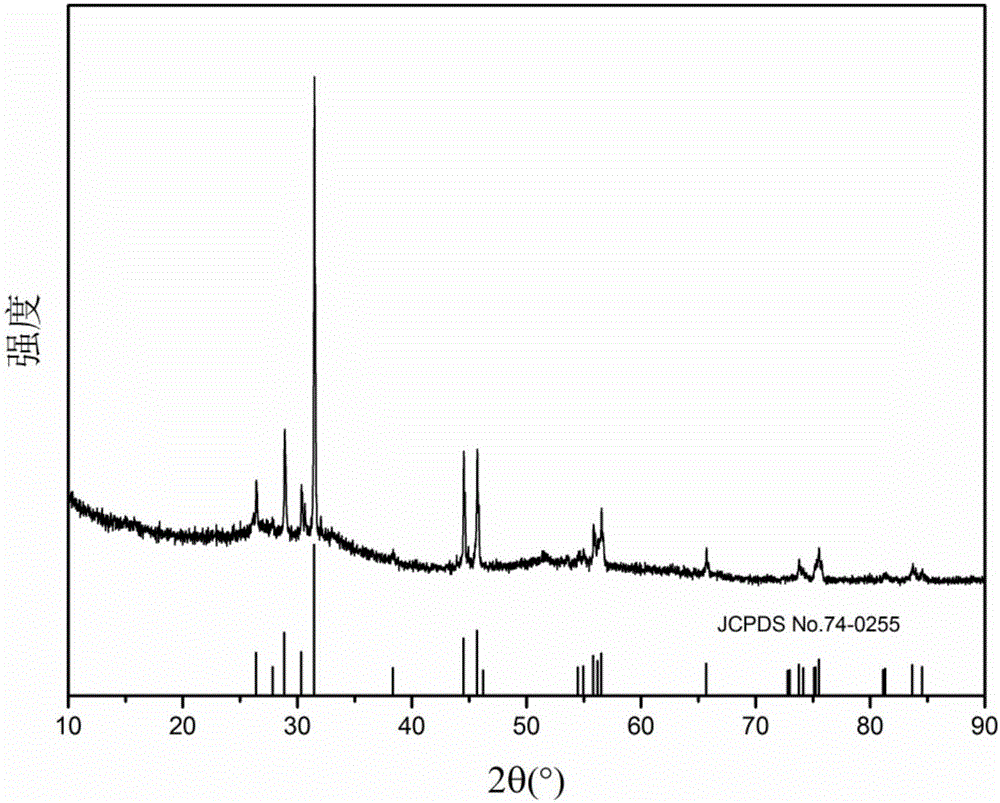

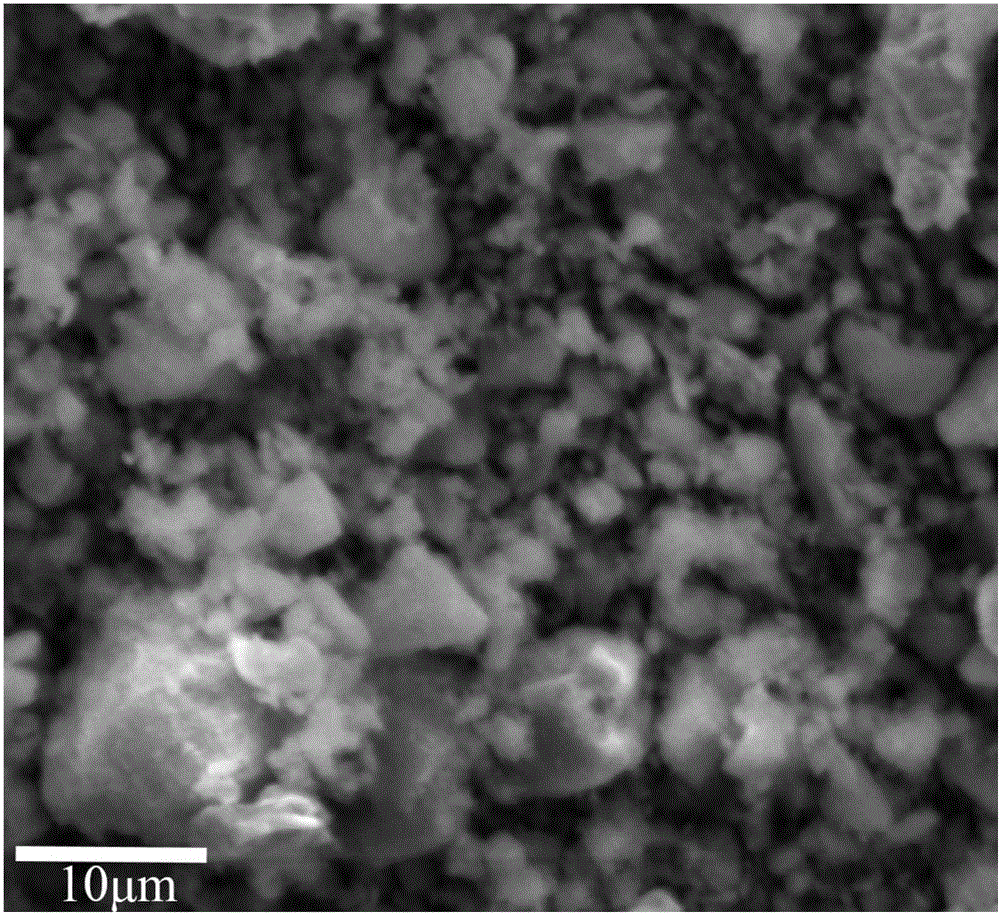

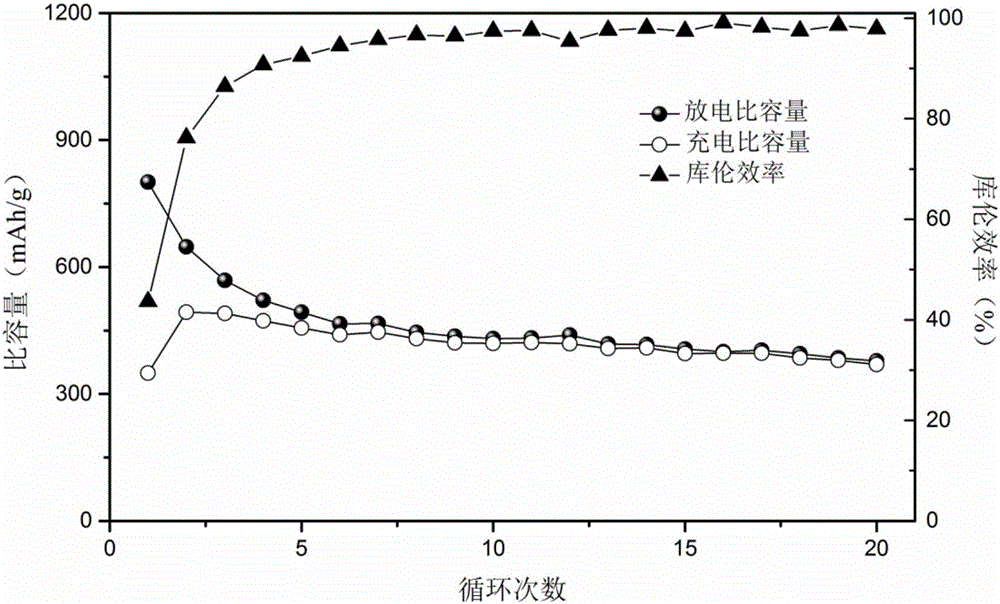

Preparation method and application of negative electrode material of tin phosphide sodium ion battery

A sodium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of specific capacity, rate performance and cycle performance to be improved, large pollution, poor safety, etc., to improve volume expansion effect Effects of agglomeration effect, high specific capacity, enhanced conductivity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In this example, a Sn 4 P 3 A preparation method for a negative electrode material for a sodium ion battery, comprising the following steps:

[0035] S1: Take 0.372g of non-toxic commercial red phosphorus, and put it into a stainless steel ball milling tank for ball milling. The ball milling beads are zirconia balls of different sizes, and the mass ratio of the balls to red phosphorus is 100:1. Argon is filled as a protective gas, the rotating speed of the ball mill is 300rpm, and the time is 3h to obtain red phosphorus with a fine particle size (<5 μm);

[0036] S2: Take 1.805g of stannous chloride dihydrate powder, add it to 80mL of ethylenediamine solvent, and stir evenly with a magnetic stirrer to obtain SnCl 2 Dispersion liquid, the concentration is 0.1mol / L;

[0037] S3: Take 0.372g of fine red phosphorus obtained in S1 and add SnCl obtained in S2 2 In the dispersion liquid, first use an ultrasonic cleaning machine for ultrasonic stirring, the power is 100W, a...

Embodiment 2

[0042] In this example, a Sn 4 P 3 A preparation method for a negative electrode material for a sodium ion battery, comprising the following steps:

[0043] S1: Take 0.558g of non-toxic commercial red phosphorus, and put it into a stainless steel ball milling tank for ball milling. The ball milling beads are zirconia balls of different sizes, and the mass ratio of the balls to red phosphorus is 100:1. Argon is filled as a protective gas, the ball milling speed is 300rpm, and the time is 0.5h to obtain red phosphorus with a fine particle size (<5 μm);

[0044] S2: Take 1.805g of stannous chloride dihydrate powder, add it to 80mL of ethylenediamine solvent, and stir evenly with a magnetic stirrer to obtain SnCl 2 Dispersion liquid, the concentration is 0.1mol / L;

[0045] S3: Take 0.558g of fine red phosphorus obtained in S1 and add SnCl obtained in S2 2 In the dispersion, first use an ultrasonic cleaning machine for ultrasonic stirring, the power is 100W, and the duration is...

Embodiment 3

[0050] In this example, a Sn 4 P 3 A preparation method for a negative electrode material for a sodium ion battery, comprising the following steps:

[0051] S1: Take 0.372g of non-toxic commercial red phosphorus, and put it into a stainless steel ball milling tank for ball milling. The ball milling beads are zirconia balls of different sizes, and the mass ratio of the balls to red phosphorus is 50:1. Argon is filled as a protective gas, the rotating speed of the ball mill is 100 rpm, and the time is 3 hours to obtain red phosphorus with a fine particle size (<5 μm);

[0052] S2: Take 1.805g of stannous chloride dihydrate powder, add it to 200mL ethylenediamine solvent, and stir evenly with a magnetic stirrer to obtain SnCl 2 Dispersion liquid, the concentration is 0.04mol / L;

[0053] S3: Take 0.372g of fine red phosphorus obtained in S1 and add SnCl obtained in S2 2 In the dispersion liquid, first use an ultrasonic cleaning machine for ultrasonic stirring, the power is 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com